Manufacturing method for n type SiC semiconductor device ohmic contact

A manufacturing method and ohmic contact technology, applied in the field of microelectronics, can solve the problems of poor ohmic contact interface matching and high ohmic contact annealing temperature, and achieve the effect of avoiding matching problems and reducing contact barriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

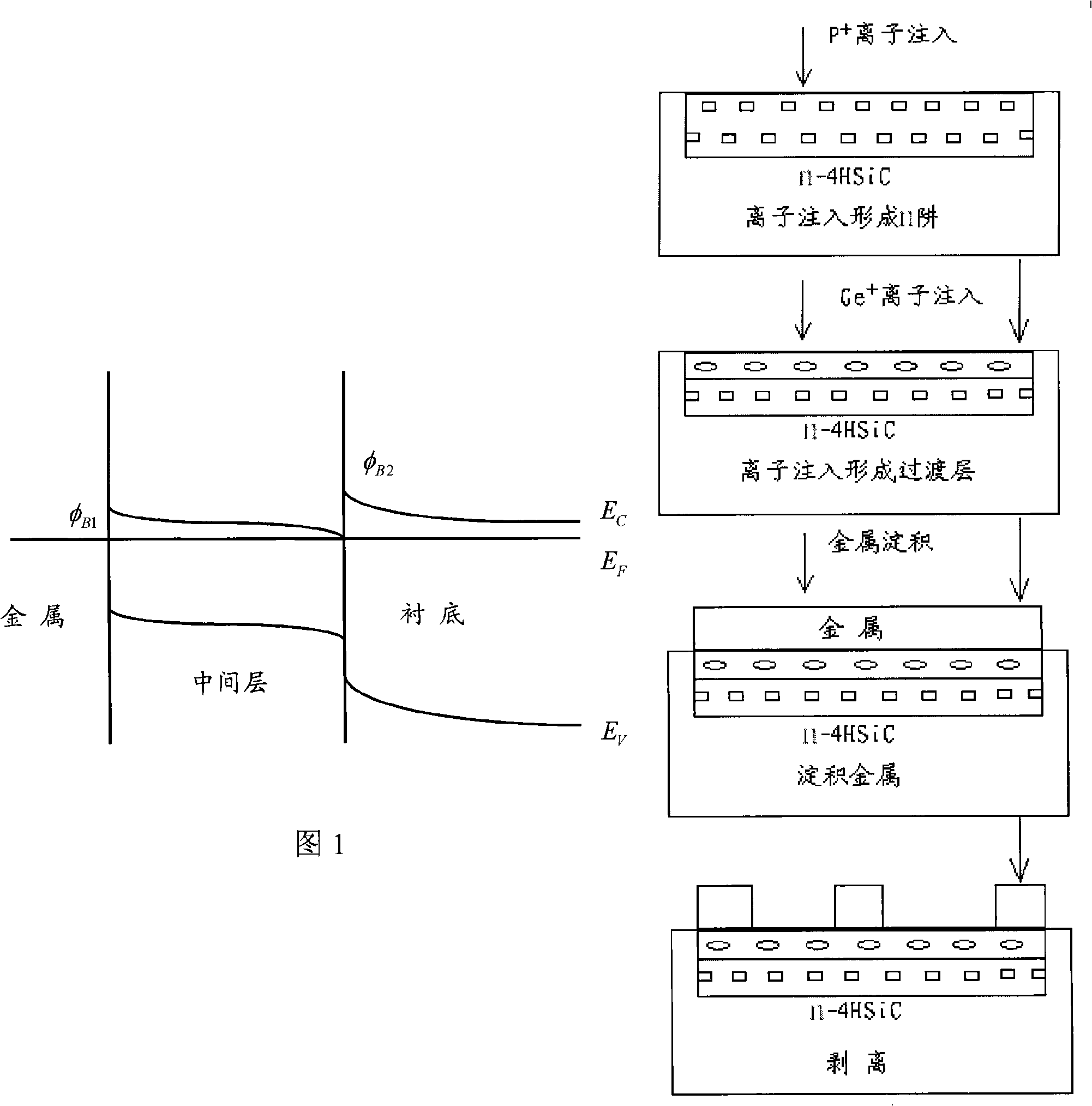

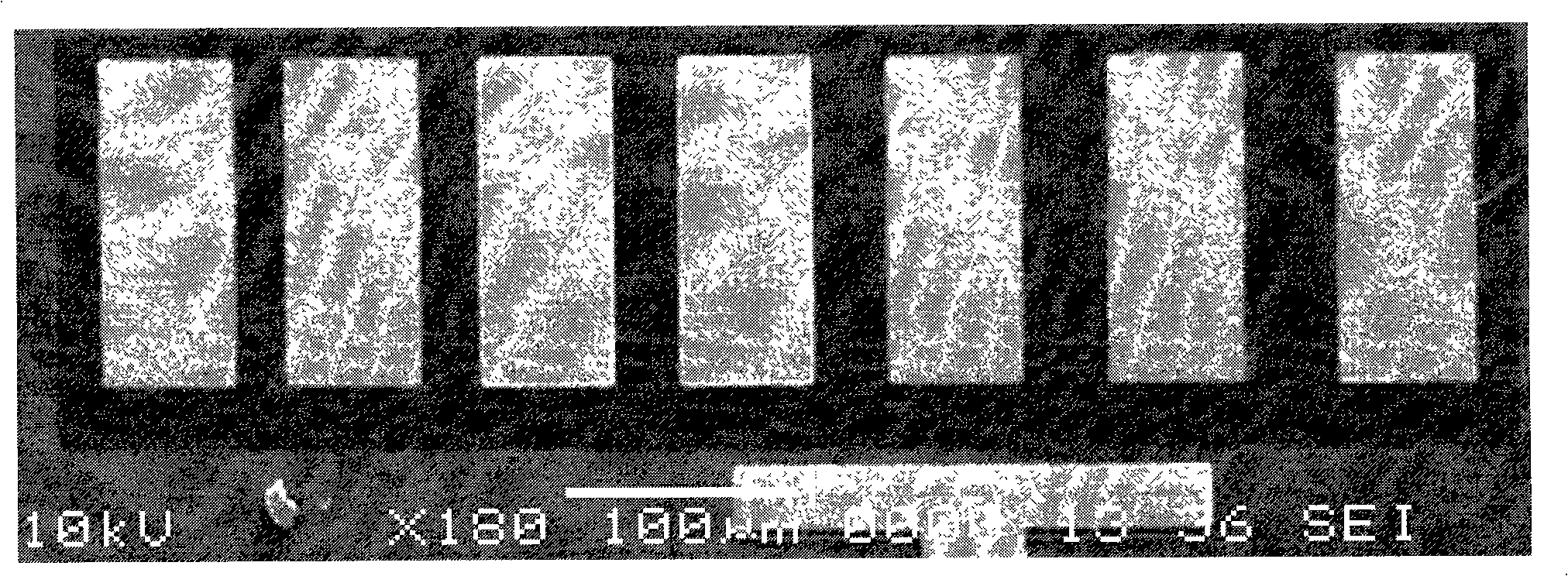

[0020] refer to figure 2 , the substrate used in the present invention is an n-type 4H-SiC substrate, and the thickness of one layer on the substrate is 5 μm, and the doping concentration Na=7.4×10 16 cm -3 The p-type 4H-SiC epitaxial layer, the ohmic contact fabrication process is as follows:

[0021] Step 1, pretreat the n-type 4H-SiC substrate, and implant the epitaxial layer with a concentration of 1×10 20 cm -3 P + ions, forming an n-well.

[0022] First, when the temperature is 550±5℃, the energy is 100keV, the dose is 8.3×10 14 cm -2 ;P + Ions were implanted into the epitaxial layer of the n-type 4H-SiC substrate.

[0023] Then, when the temperature is 550±5℃, the energy is 50keV, and the dose is 2.5×10 15 cm -2 . P + Ions were implanted on the epitaxial layer of the n-type 4H-SiC substrate to form a concentration of 1×10 20 cm -3 The n-well.

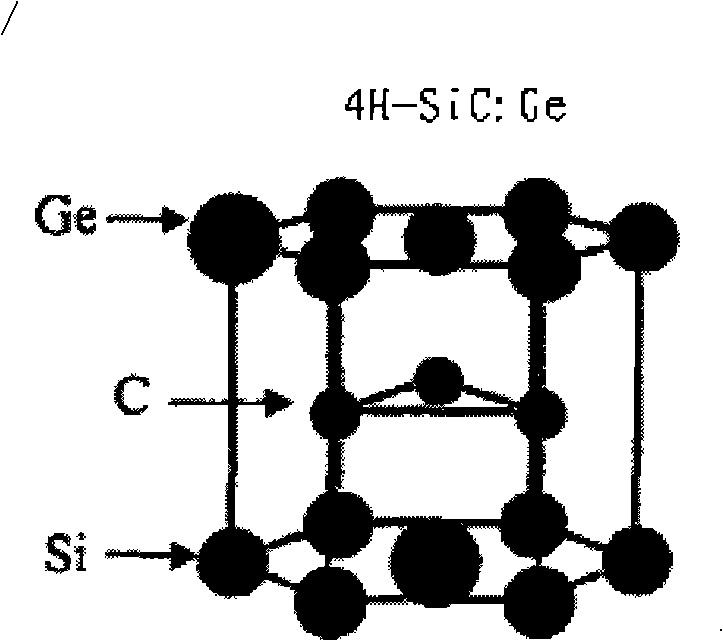

[0024] Step 2, the implantation concentration on the 4H-SiC material forming the n well is at least 10 21 cm -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com