Ultra-thin plate type heater and manufacturing method thereof

A technology of heater and ultra-thin plate, which is applied in the direction of ohmic resistance heating, electric heating device, manufacturing stator/rotor body, etc., can solve the problems of inapplicability, and achieve the effect of fast heating speed, not easy to bend, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

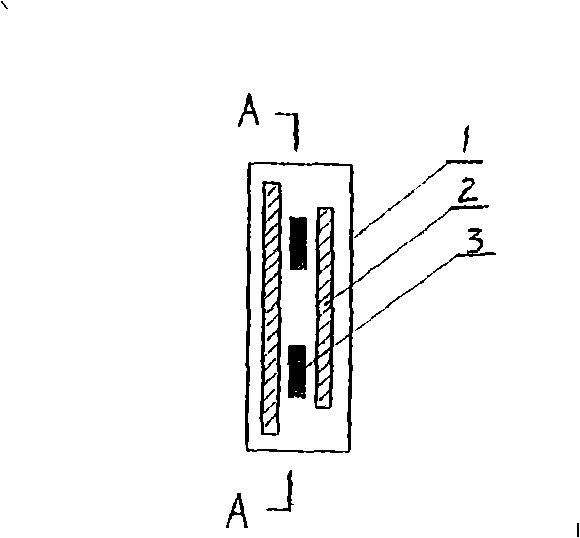

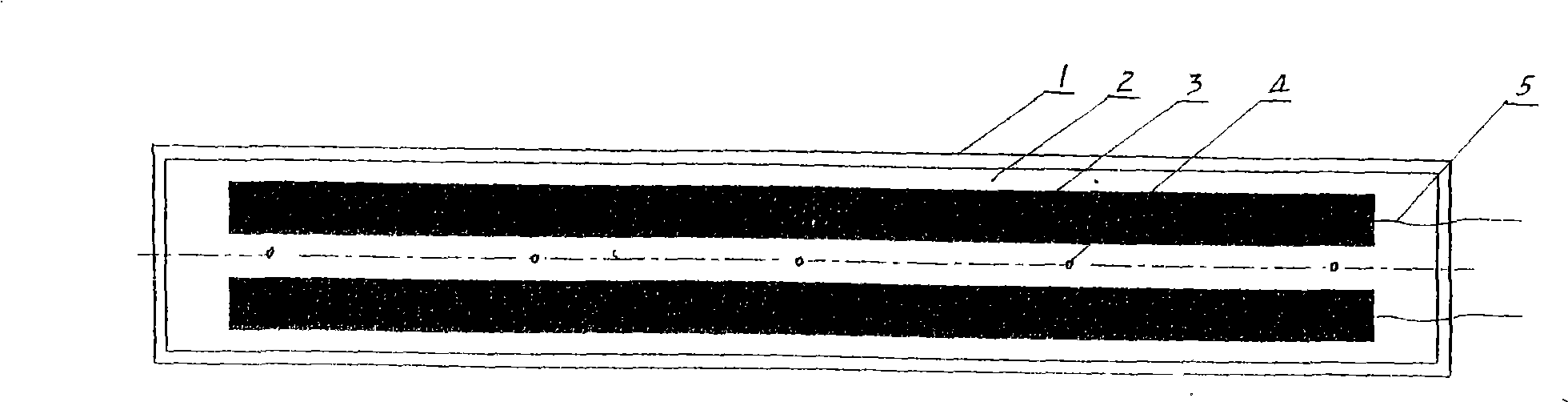

[0022] The invention is an ultra-thin plate heater and a manufacturing method thereof. The heater includes a lead wire 5, and is characterized in that the heater is provided with a rectangular thin-plate housing 1 whose length and width match the air flow grooves of the turbine generator rotor, and two thin silicon wafers are arranged longitudinally on both sides of the housing. 2. Between the two silicon wafers, on both sides of the longitudinal centerline, two thin heating elements 3 are arranged in parallel and symmetrically. In addition, in order to increase the strength, riveting holes 4 are evenly arranged on the longitudinal center line of the rectangular thin-plate housing 1.

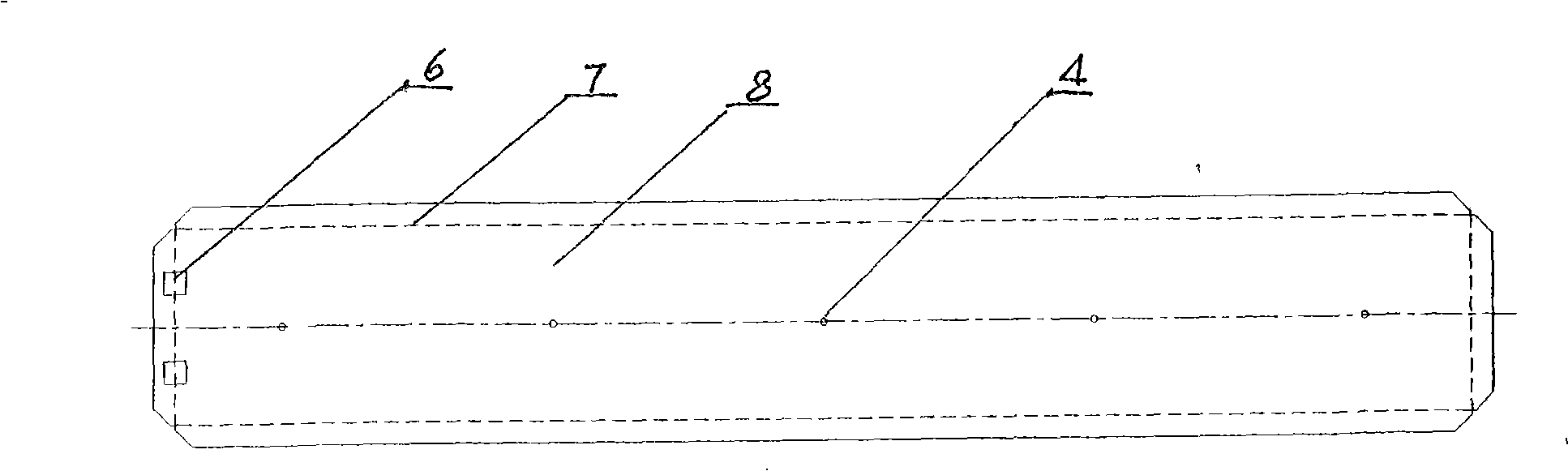

[0023] The manufacturing method of the present invention is: the ultra-thin plate heater shell is composed of an upper plate 8 and a lower plate 9 respectively, and folds are arranged around the upper plate 8. The production process is like this:

[0024] First, cut the upper and lower plates, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap