Defective cigarette holder processing and recovering technique

A technology of defective cigarettes and cigarette holders, which is applied in the direction of solid separation, filter screen, grille, etc., to achieve the effects of avoiding outflow, good social benefits, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

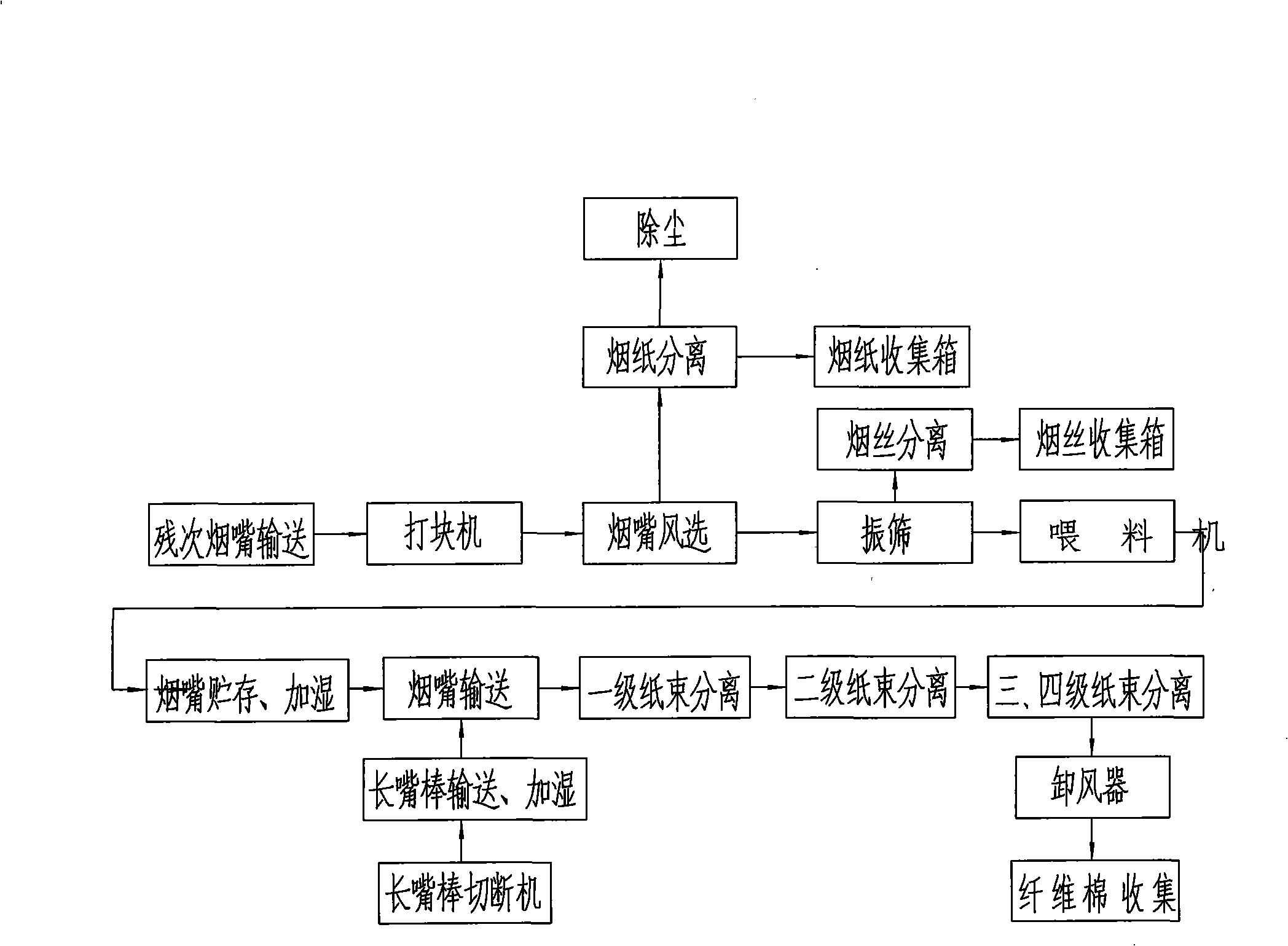

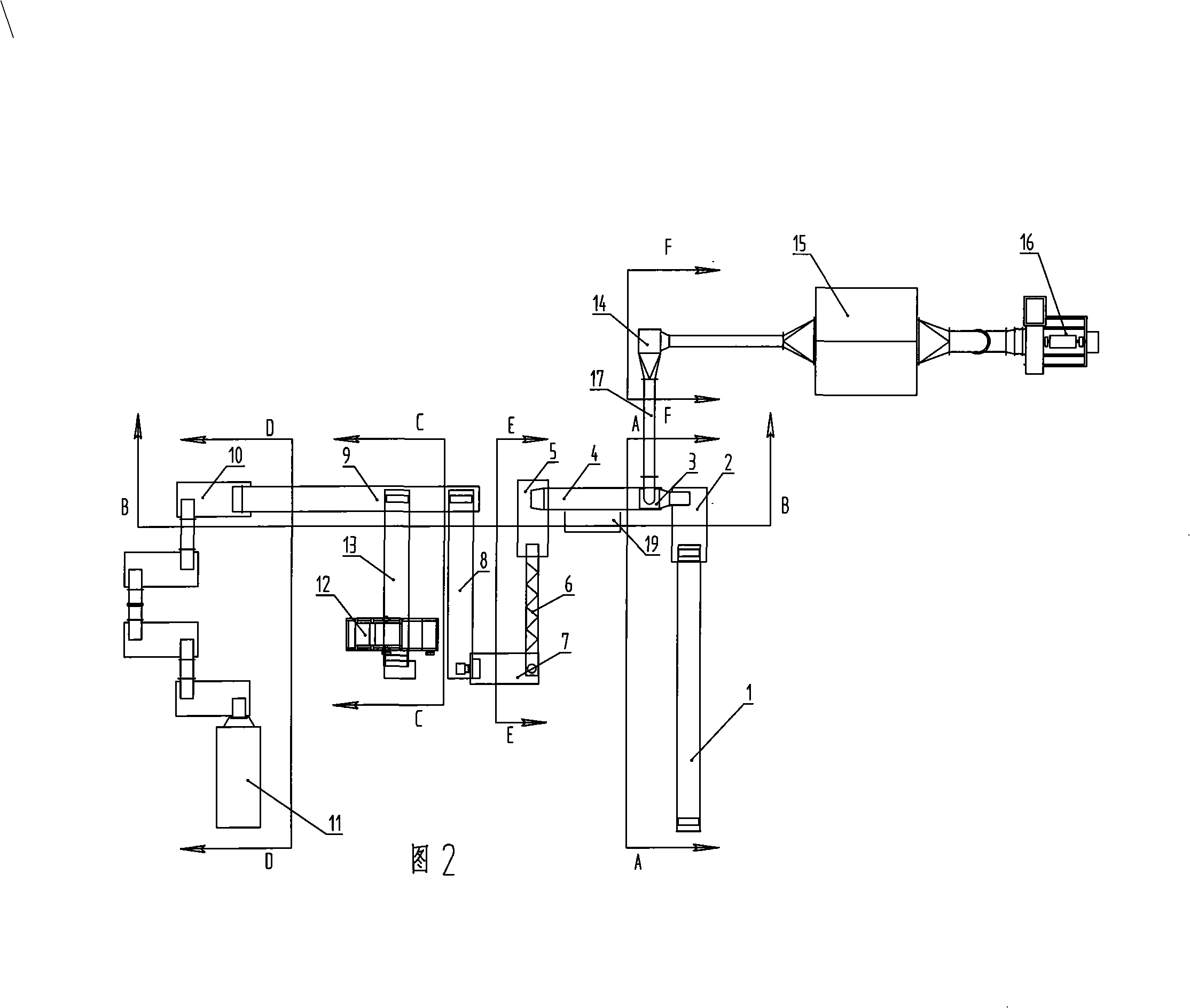

[0023] Such as figure 1 , as shown in Figure 2, the process flow of this process includes: working step 1: cigarette holder pieces are broken up, winnowing; working step 2: cigarette holder screening, automatic humidification, storage, flow control; working step 3: cigarette holder paper removal, cotton output 1. Separation of paper bundles; working step four: unloading and collecting fiber cotton.

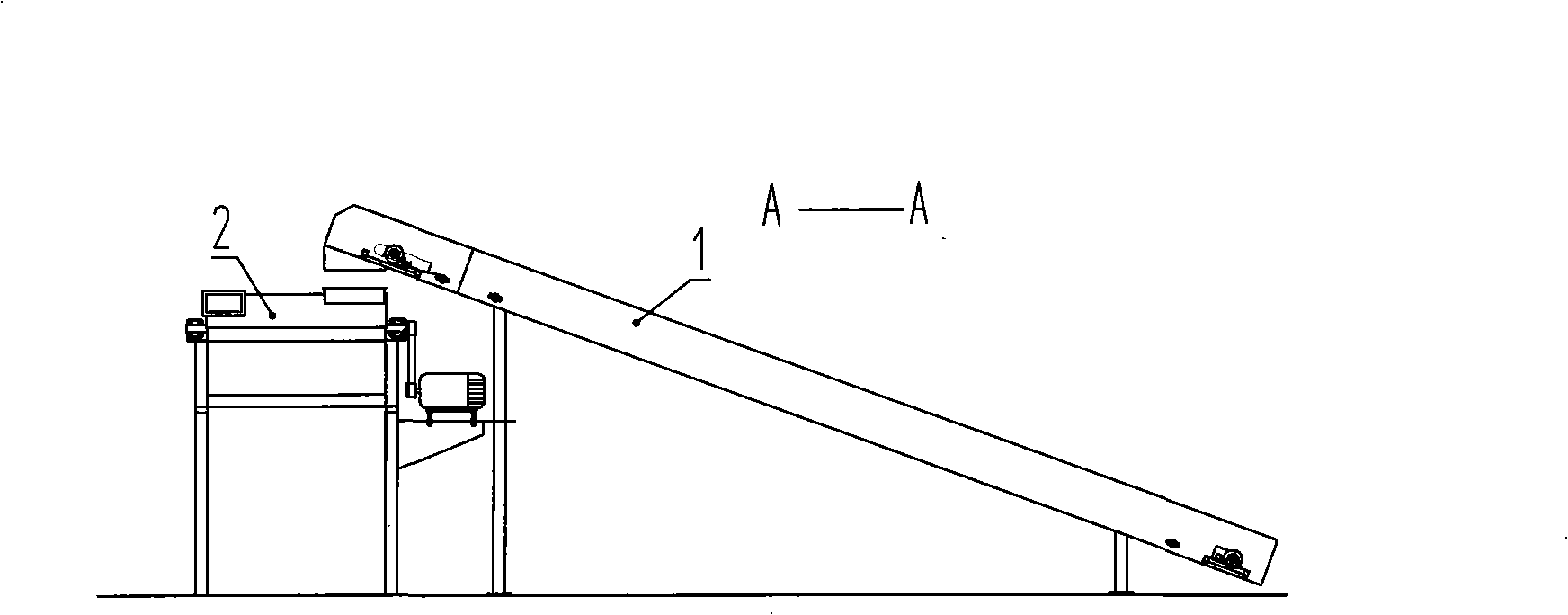

[0024] Such as figure 1 ,figure 2, image 3 , Figure 8 As shown, the first step of the process: the cigarette holder blocks are broken up and winnowed, and the process is as follows: the defective cigarette holders produced in the production of the cigarette factory are generally compressed into blocks for the convenience of storage and transportation, and then enter the cigarette holders for processing and recycling When crafting, break it up first. The defective cigarette holders that are compressed into blocks enter the block machine 2 through the belt conveyor I 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com