Process for extracting insoluble sulfur

A sulfur-soluble technology, applied in the preparation/purification of sulfur, etc., can solve problems such as solvent loss without extraction effect, industrial application of unseen technology, low extraction effect, etc., to solve the problem of toxicity and safety, and reduce equipment Investment cost, good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

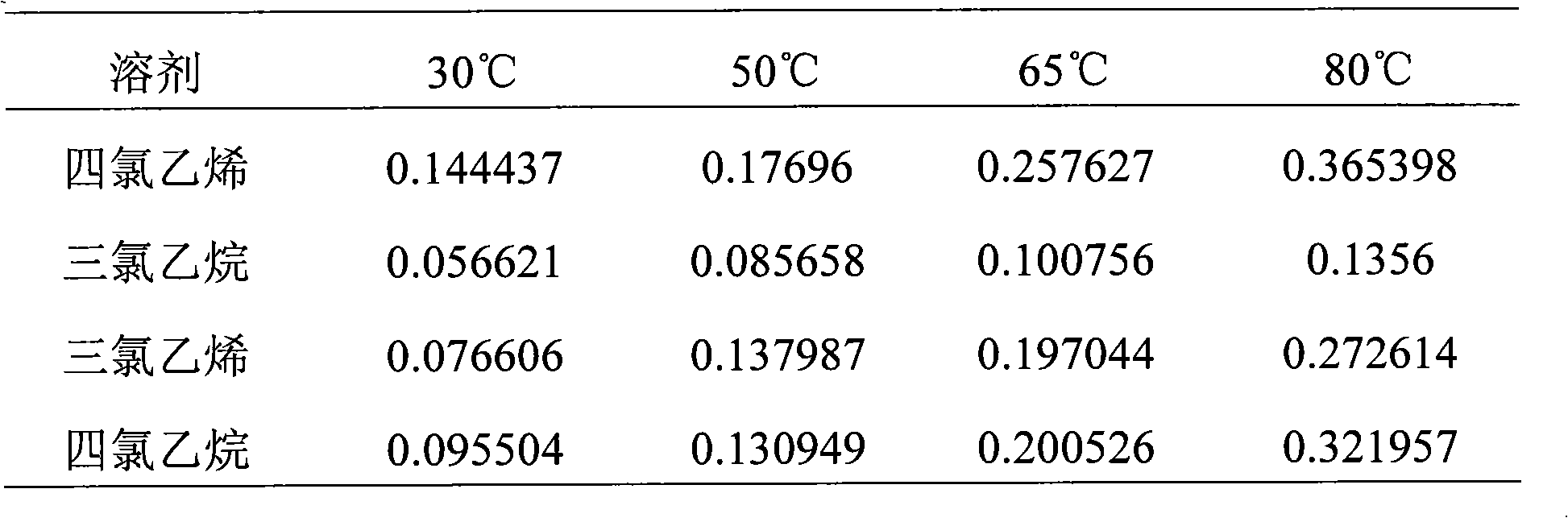

[0023] The industrial insoluble sulfur crude product with an IS mass content of 48.6% is used as a raw material, and the solvent of the present invention is used as an extraction agent. At an extraction temperature of 80°C and an extraction time of 15 minutes, the extraction experiment is carried out by adjusting the solvent ratio, and the content of IS in the obtained product is See Table 2 below.

[0024] Table 2 adopts solvent of the present invention to be extraction agent experimental result

[0025] Solvent ratio (m:m)

Embodiment 3-4

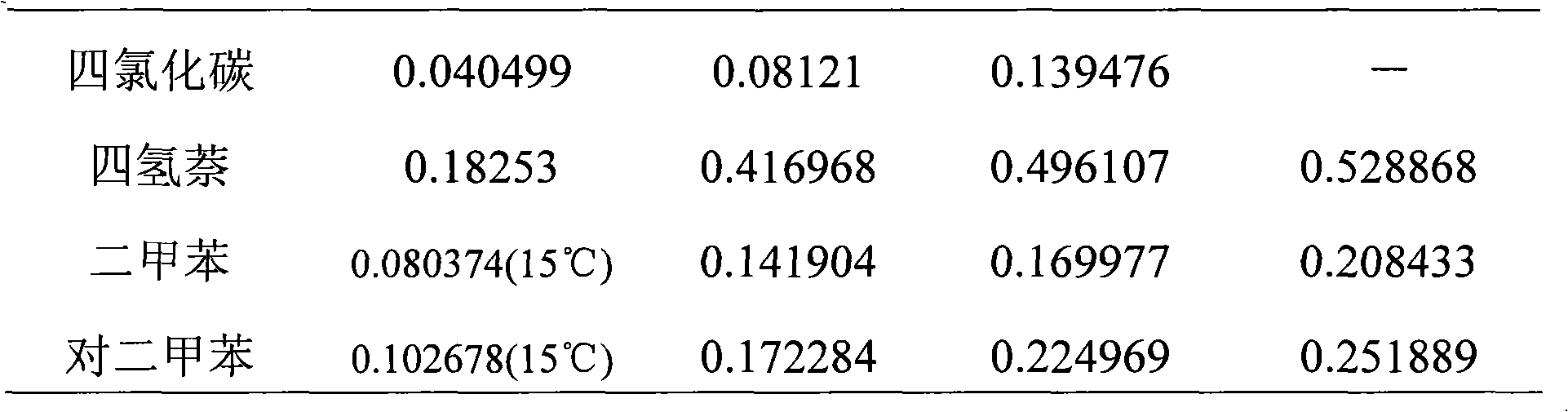

[0027] Insoluble sulfur crude products with different IS contents are used as raw materials, industrialized carbon disulfide, tetrachlorethylene and the solvent of the present invention are respectively used as extraction agents, and the extraction temperature is 80°C (25°C for carbon disulfide), and the extraction time is 15 minutes. In the extraction experiment, the content of IS in the obtained product is shown in Table 3 below.

[0028] Table 3 adopts solvent of the present invention, tetrachlorethylene, carbon disulfide to the extraction result of different raw materials

[0029]

[0030] From the results of Table 3, it is obvious that the extraction effect of the extraction solvent of the present invention when purifying the insoluble sulfur product is equivalent to the carbon disulfide solvent, but obviously better than the tetrachlorethylene solvent.

Embodiment 5-9

[0032] Using the industrial insoluble sulfur crude product with an IS mass content of 48.6% as a raw material, the extraction time is 15 minutes, the extraction effects of the solvent of the present invention at different temperatures and solvent ratios are shown in Table 4 below.

[0033] Table 4 is the extraction result of solvent of the present invention under different temperature and solvent ratio

[0034] Solvent ratio, m:

[0035] As can be seen from the results in Table 4, the extraction effect of the solvent will decrease if the extraction temperature is lowered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com