Synthetic method of polyarylene sulfide resin

A technology of polyarylene sulfide and synthesis method, applied in the field of polymer materials, can solve problems such as large solvent loss, and achieve the effects of reducing solvent loss, low production cost and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

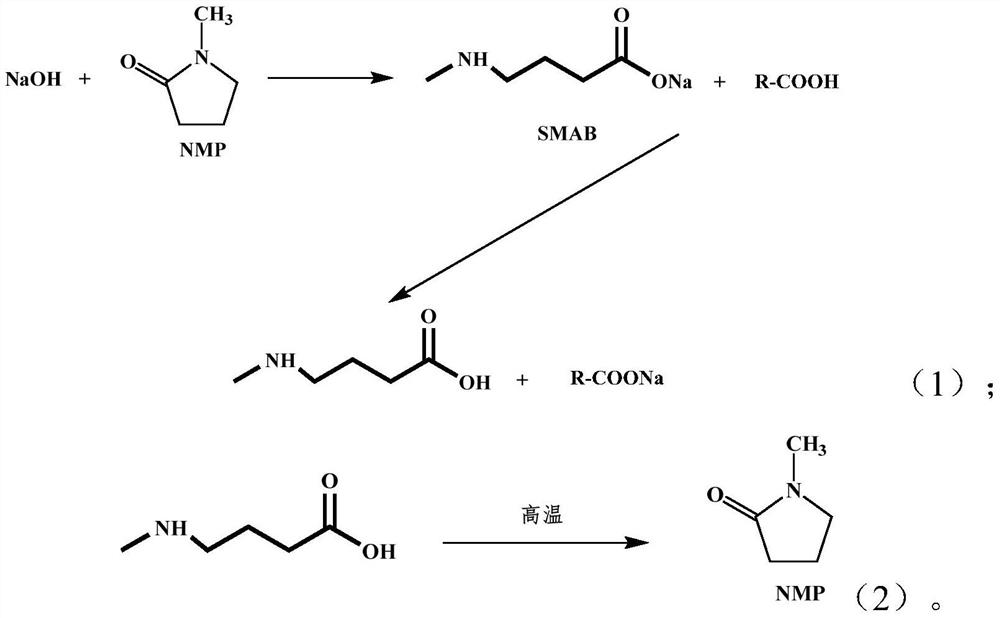

Method used

Image

Examples

Embodiment 1

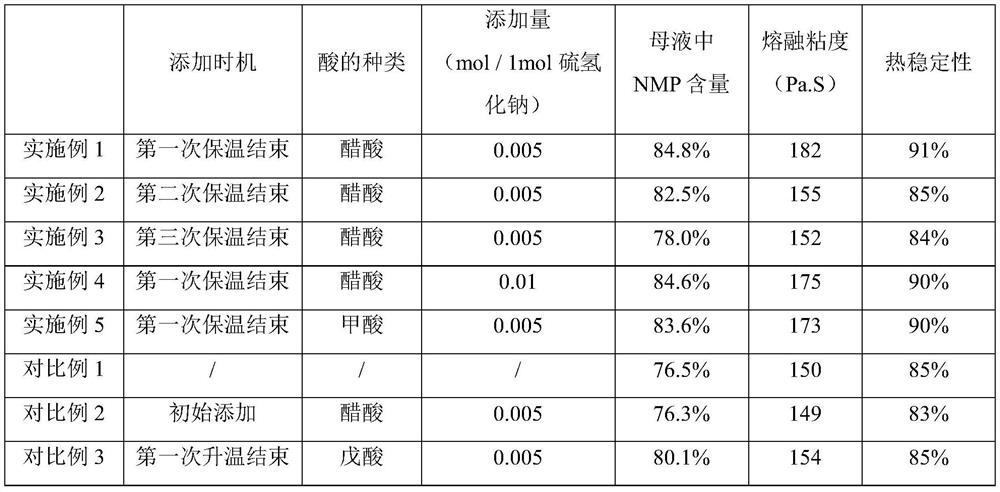

[0041] Dehydration: In a 1000L reactor, add 1000mol of sodium hydrosulfide, NaOH / sodium hydrosulfide (mol / mol)=1.01, NMP / sodium hydrosulfide (mol / mol)=2.5, at a stirring speed of 200rpm and under nitrogen protection, At a speed of 1.5°C / min, the temperature was raised to 200°C for dehydration, 124.4Kg of aqueous solution (water content 94.2%) was removed, and then the temperature was lowered to 110°C.

[0042] Polymerization: continue to add p-dichlorobenzene (PDCB) and solvent NMP to the reactor, and in the final reaction system, PDCB / sodium hydrosulfide (mol / mol)=1.02, and NMP / sodium hydrosulfide (mol / mol)=3.5. Raise the temperature to 220°C at a rate of 2°C / min, and add acetic acid after keeping the temperature for 1 hour. The amount added is 0.005mol / 1mol sodium hydrosulfide. Then the temperature was raised to 270°C at a rate of 1°C / min, and kept for 2 hours; then cooled to 240°C at 1°C / min, kept for 0.5h, and finally cooled to 150°C at 2°C / min to obtain polyarylene sulfide ...

Embodiment 2~6

[0046] On the basis of Example 1, the type, timing and amount of organic monobasic acid were changed, as shown in Table 1 below. The properties of the polyphenylene sulfide prepared in each example are also listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com