Dual-solvent extraction of oil sand bitumen

a technology of oil sand bitumen and solvent, which is applied in the petroleum industry, liquid hydrocarbon mixture production, etc., can solve the problems of economic losses and environmental problems, fire hazards caused by the use of light or intermediate solvents, and recoveries of bitumen, so as to optimize the recovery and separation rate of bitumen, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

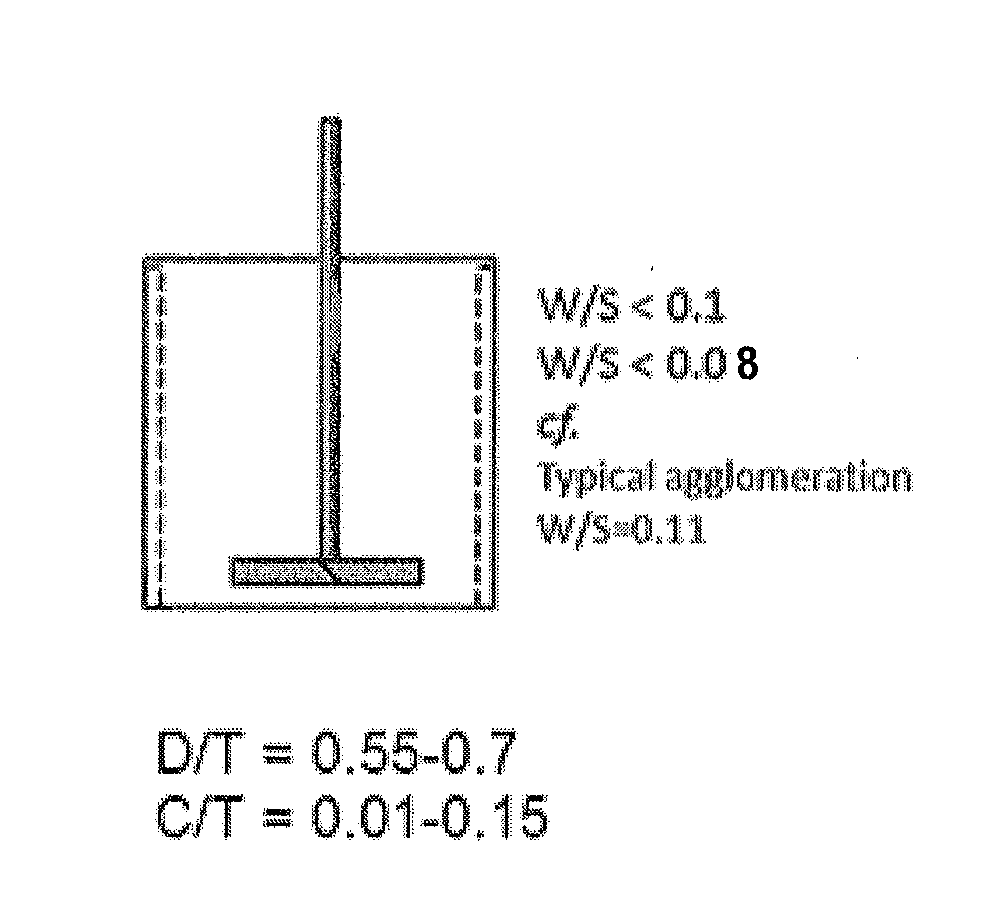

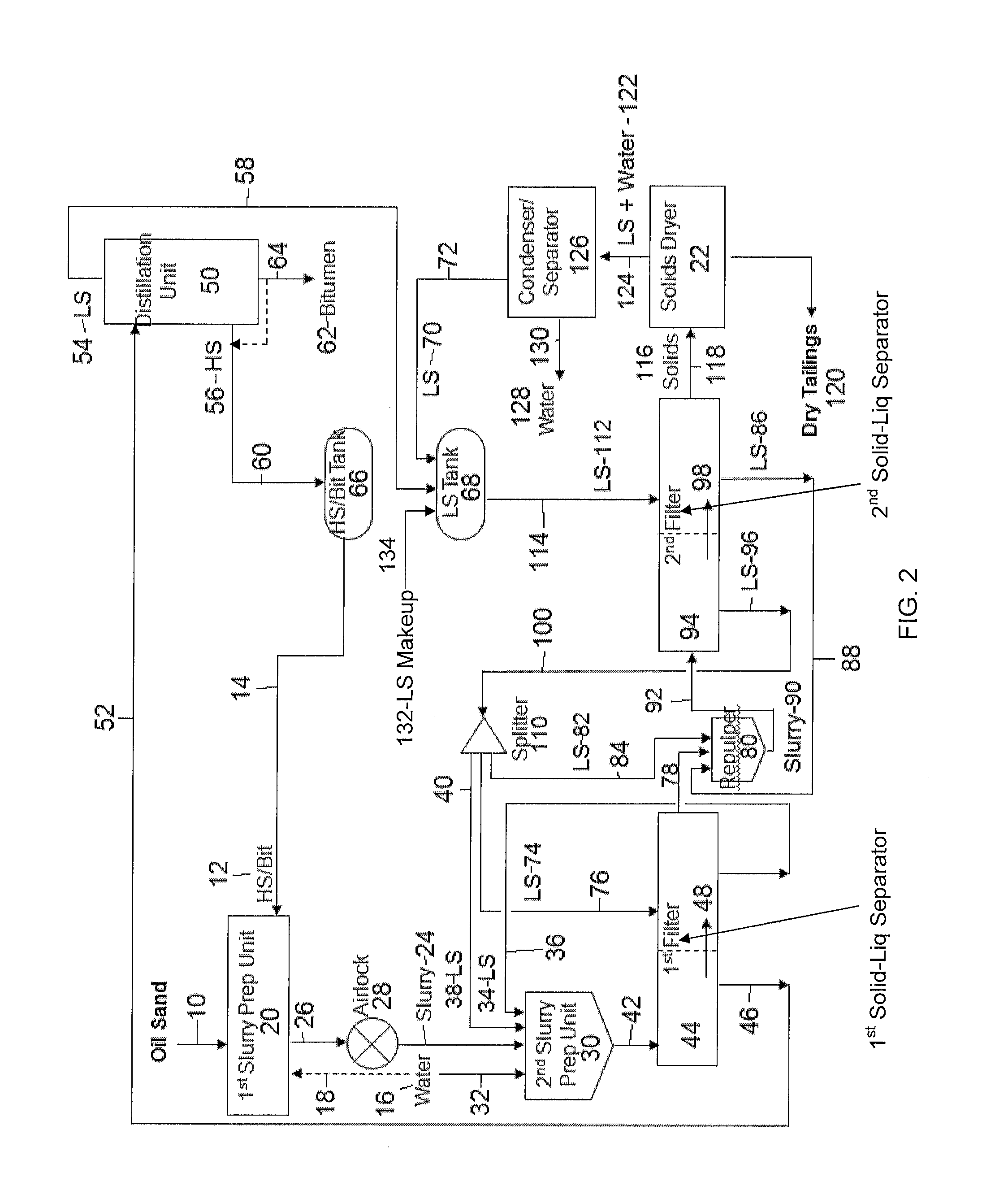

[0069]Table 1 shows the relationship of water-to-solids mass ratios (W / S) in slurry and filtration rates for a test oil sand (#1) containing 9.3 wt % bitumen, 2.1 wt % water and 88.6 wt % solids. The fines (<44 μm) content in the solids was 21 wt %. This oil sand was relatively dry, so by varying the water dosage, the W / S could be adjusted in a wider range. The hydrocarbon phase in the slurry prior to the first filtration step comprised about 30 wt % bitumen, 35 wt % virgin light gas oil and 35 wt % heptane. The solids content in the slurry was about 58 wt %. The solids were flocculated in a baffled dished-bottom mixing tank of 13 cm in diameter (T) at 50° C. The impeller was a 6-blade 45° PBT of 7.6 cm in diameter (D). The bottom clearance (C) was about 1.5 cm. Thus, D / T=0.58 and C / T=0.12. The down-pumping axial impeller was operated at 600 rpm for 4 minutes, providing a power input of about 6 W / kg of slurry. The mixed slurry was transferred to a top-loading batch filter with about...

example 2

[0071]Two samples of oil sands #1 and #2 having 9.3 wt % and 9.7 wt % bitumen, 2.1 wt % and 6.2 wt % water and 21% and 28% fines in solids, respectively, were extracted with dual solvents under similar conditions as described in Example 1. The test for oil sand #2 had zero water addition. Oil sand connate water was the sole source of water for solids flocculation. Both samples went through four stages of filtration with repulping between stages 2 and 3. The filter cake thickness was kept around 4.3 cm. All wash liquids were prepared based on their compositions and flow rates in a continuous process. Table 2 shows the extraction performance.

TABLE 2Initial FiltrateFilter ProcessBitumenW / S MassFluxRateRecovery*Ratio inOil sand(L / m2 s)(t / m2 h)(%)Slurry#15.97.096.90.052#211.18.594.10.074*Bitumen recovery here includes small loss of HS to spent solids that can be deducted from the product bitumen in distillation as HS makeup.

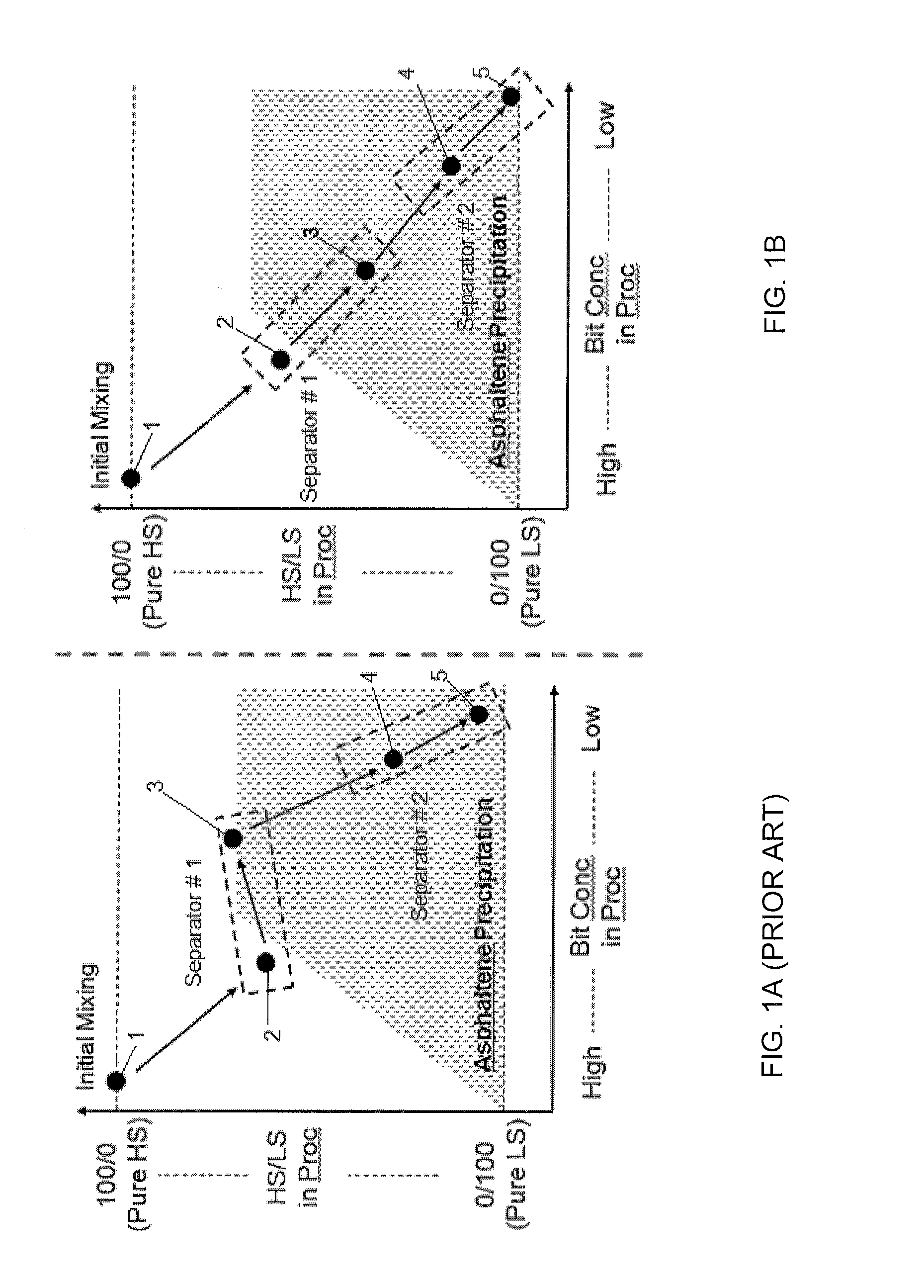

[0072]The bitumen recoveries for oil sands #1 and #2 in water-ba...

example 3

[0073]Tests were conducted to compare the filter process rates and bitumen recoveries achieved using a solids agglomeration method of the prior art which involved a drum agglomerator verses the solids flocculation method of the present invention which involved the mixing tank / impeller described in Example 1, The two solvents used in extraction and the slurry compositions were identical in these two tests and similar to those in Example 1. An oil sand (#3) used in both tests contained about 10 wt % bitumen, 5 wt % water and 85 wt % solids. The fines (<44 μm) content in the solids was 28 wt %. The solids contents in the slurry for the agglomeration and flocculation tests were about 45 wt % and 52 wt %, respectively. The filter cake thicknesses used in the agglomeration and flocculation tests were 10.2 cm and 4.7 cm, respectively. The agglomeration data have been converted based on a hypothetical filter cake thickness of 4.7 cm to be comparable with the flocculation data. Table 3 shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass ratio | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| mass ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com