Method for preparing big and medium hole high performance active carbon

A high-performance, activated carbon technology, used in the manufacture of wood-based activated carbon, can solve the problem of low strength of granular carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

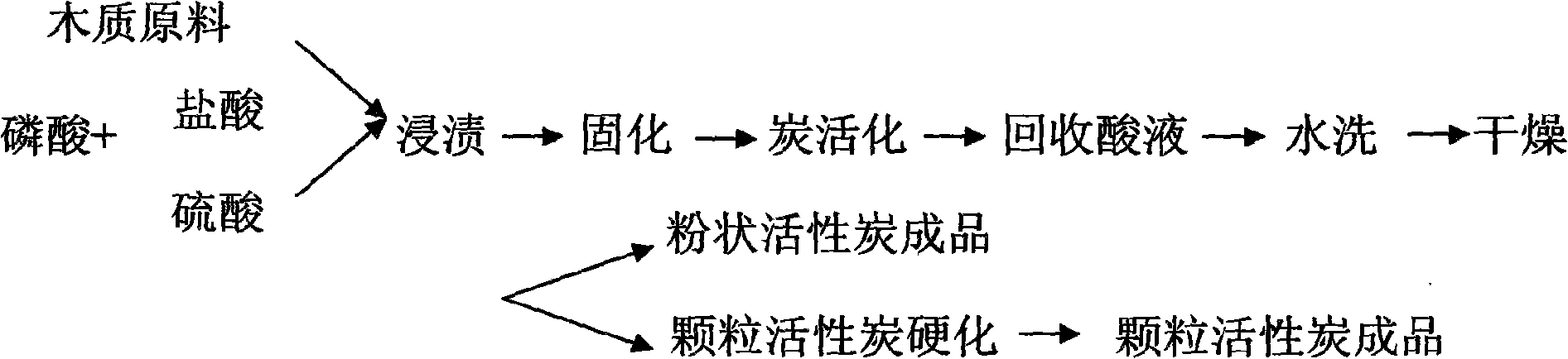

Image

Examples

Embodiment 1

[0011] 10 parts of dry apricot shells of 10-20 mesh, impregnated with 30-85% concentration of phosphoric acid, concentrated sulfuric acid, hydrochloric acid mixed acid (the amount of concentrated sulfuric acid and hydrochloric acid is 2-10% of the amount of phosphoric acid), and the immersion temperature is 40-120 ℃, the immersion time is 4-24 hours, after immersion, filter off the excess immersion liquid, soak the apricot shells and cure them at 40 ℃-120 ℃ for 6-24 hours, and the cured phosphoric acid apricot husks are activated at 300-700 ℃ for 0.5 -4 hours. After activation, recover the acid in the activated material, wash, dry and solidify at 100-500°C for 0.5-3 hours to obtain 3.3 parts of finished granular activated carbon. After testing: the methylene blue adsorption value of apricot shell granular activated carbon is as high as 300mg / g (20ml / 0.1g), the caramel decolorization rate of method B is 160%, the iodine adsorption value is 1200mg / g, the granular carbon strength...

Embodiment 2

[0013] 10 parts of dried coconut shells of 6-8 mesh, impregnate 10-24 hours at 80-120°C for 10-24 hours with phosphoric acid of 30-85% concentration and 2-10% of the phosphoric acid content of concentrated sulfuric acid and hydrochloric acid. The impregnation solution, the impregnated coconut shell is cured at 40°C-120°C for 4-24 hours, and the cured phosphoric acid coconut shell is activated at 300-700°C for 0.5-4 hours. After activation, recover the acid in the activated material, wash, dry and solidify at 100-500°C for 0.5-3 hours to obtain 3.3 parts of finished granular activated carbon. After testing: the methylene blue adsorption value of coconut shell granular activated carbon reaches 285mg / g (19ml / 0.1g), the caramel decolorization rate of method B is 150%, the iodine adsorption value reaches 1200mg / g, the granular carbon strength is greater than 80%, and the yield is 33% .

Embodiment 3

[0015] 10 parts of dry-dried walnut shells of 10-20 mesh, soaked at 60-120°C for 10-24 hours with 30-85% phosphoric acid and 2-10% of phosphoric acid, concentrated sulfuric acid, hydrochloric acid, and filtered to remove excess The impregnating liquid, the soaked walnut shell is cured at 40°C-120°C for 4-24 hours, and the cured phosphoric acid walnut shell is activated at 300-700°C for 0.5-4 hours. After activation, recover the acid in the activated material, wash, dry and solidify at 100-500°C for 0.5-3 hours to obtain 3.3 parts of finished granular activated carbon. After testing: the methylene blue adsorption value of walnut granular activated carbon is as high as 292mg / g (19.5ml / 0.1g), the caramel decolorization rate of method B is 160%, the iodine adsorption value is 1200mg / g, the granular carbon strength is 80%, and the yield is 33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption value of blue | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com