Method for extracting sea-buckthorn protein from sea-buckthorn seed meal

A technology of seabuckthorn protein and seabuckthorn seeds, which is applied in the field of protein extraction, can solve the problems of insufficiently high seabuckthorn protein content and darker color, and achieve the effects of improving comprehensive utilization, increasing added value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

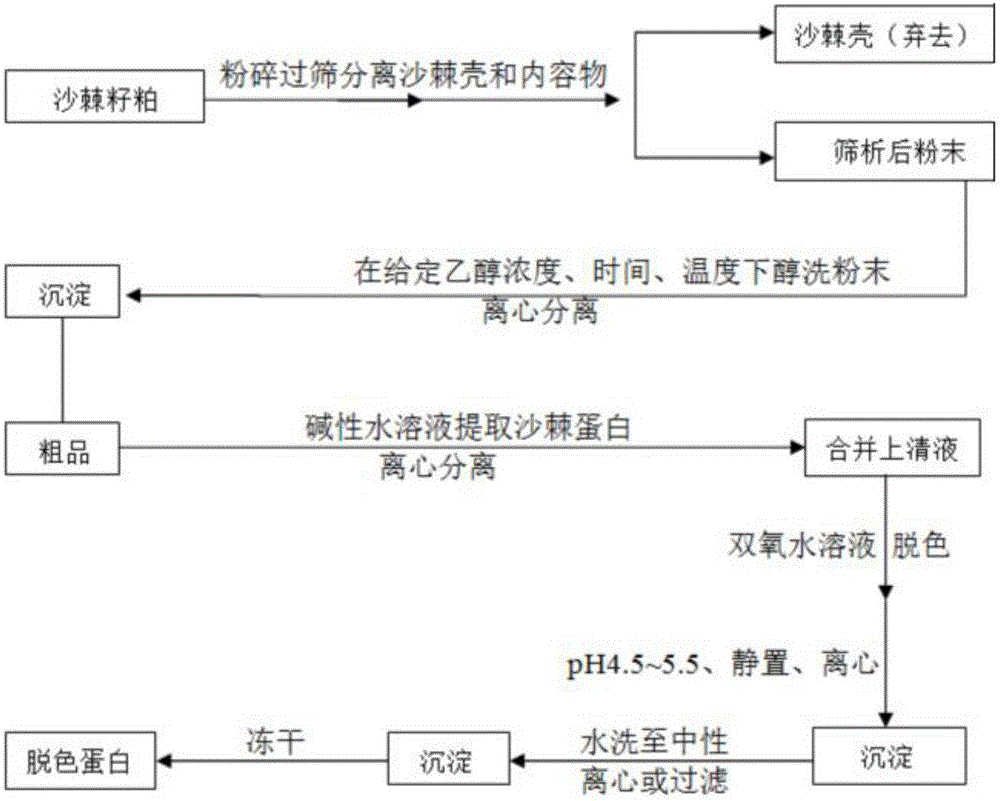

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 225g of seabuckthorn seed meal and crush it for 35S in a ZN-10 small pulverizer with a power of 1.5Kw, and then pass through a 40-mesh sieve to obtain seabuckthorn seed meal fine powder;

[0033] Step two, take 10g of sieved and subdivided into a round bottom flask, add 60% ethanol solution according to 1:6 material-liquid ratio, stir and extract 3 times on a constant temperature magnetic stirrer at 50℃, each 60min, centrifuge (3000PRM, 20min), collect the precipitate and wash with water until it is neutral;

[0034] Step 3: Add water to the precipitate after washing with water according to the ratio of material to liquid at 1:12, stir and mix well, adjust the pH to 10 with 0.1 mol / L sodium hydroxide, stir and extract 3 times at 50°C, each time for 50 minutes, centrifuge at 3000PRM for 20 minutes , Collect and combine the supernatants, add 30% hydrogen peroxide solution (30% hydrogen peroxide to alkaline extract ratio 1:20) to the supernatant, stir at 45°C for ...

Embodiment 2

[0037] Step 1: Weigh 225g of sea-buckthorn seed meal and crush it for 35S in a ZN-10 small pulverizer with a power of 1.5Kw, then pass through a 60-mesh sieve to obtain sea-buckthorn seed meal fine powder;

[0038] Step two, take 10g of sieved and subdivided into a round bottom flask, add 60% ethanol solution according to 1:6 material-liquid ratio, stir and extract 3 times on a constant temperature magnetic stirrer at 50℃, each 60min, centrifuge (3000PRM, 20min), collect the precipitate;

[0039] Step 3: Add water to the precipitate after washing with water according to the ratio of material to liquid at 1:12, stir and mix well, adjust the pH to 10 with 0.1 mol / L sodium hydroxide, stir and extract 3 times at 50°C, each time for 50 minutes, centrifuge at 3000PRM for 20 minutes , Collect and combine the supernatants, add 30% hydrogen peroxide solution (30% hydrogen peroxide to alkaline extract ratio 1:20) to the supernatant, stir at 45°C for 60 minutes, and then adjust the pH to 0.1m...

Embodiment 3

[0042] Step 1: Weigh 225g of seabuckthorn seed meal and crush it for 35S in a ZN-10 small pulverizer with a power of 1.5Kw, and pass it through an 80-mesh sieve to obtain seabuckthorn seed meal fine powder;

[0043] Step two, take 10g of sieved and subdivided into a round bottom flask, add 60% ethanol solution according to 1:6 material-liquid ratio, stir and extract 3 times on a constant temperature magnetic stirrer at 50℃, each 60min, centrifuge (3000PRM, 20min), collect the precipitate.

[0044] Step 3: Add water to the precipitate after washing with water according to the ratio of material to liquid at 1:12, stir and mix well, adjust the pH to 10 with 0.1 mol / L sodium hydroxide, stir and extract 3 times at 50°C, each time for 50 minutes, centrifuge at 3000PRM for 20 minutes , Collect and combine the supernatants, add 30% hydrogen peroxide solution (30% hydrogen peroxide to alkaline extract ratio 1:20) to the supernatant, stir at 45°C for 60 minutes, and then adjust the pH to 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com