Plant-derived flavoring and seasoning base material and preparation method thereof

A seasoning base material and plant-sourced technology, which is applied in food science, sugar-containing food ingredients, food ingredients as anti-microbial preservation, etc., can solve the problems of difficult to meet consumers' taste needs and single color, and achieve rich color varieties, The effect of increasing the degree of hydrolysis and increasing the added value of the oil industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

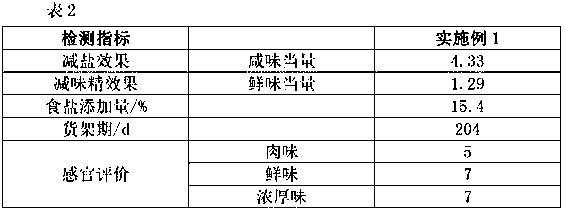

Embodiment 1

[0035] The specific preparation operation steps of a kind of plant source flavoring seasoning base material are as follows:

[0036] (1) Preparation of defatted linseed meal powder enzymatic hydrolyzate

[0037] Get the defatted linseed meal powder 1000g that protein content is 25%, at first add the total 40g of alkaline protease and tyrosinase by the amount of 4% of defatted cake powder quality, alkaline protease and tyrosinase are respectively 33.3g and 6.7g, that is, the mass ratio is 5:1; add 8.3L water to adjust the mass concentration of defatted cake powder to 12%, adjust the pH value to 7.0 with phosphate buffer solution; react for 1.5 h at a temperature of 45 °C; Add 10g of tyrosinase and flavor protease to the amount of 1% of the mass of meal flour, tyrosinase and flavor protease are 2.5g and 7.5g respectively, that is, the mass ratio is 1:3, and the pH value is adjusted to 5.5 with phosphate buffer solution ; under the condition of temperature 40 ℃, the reaction tim...

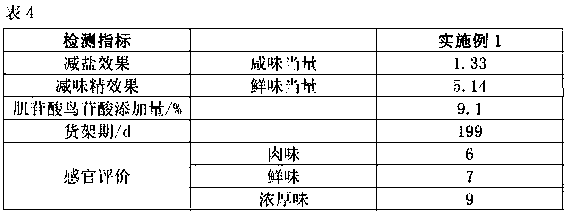

Embodiment 2

[0060] The specific production operation steps of a kind of plant source flavor-enhancing seasoning base material are as follows:

[0061] (1) Preparation of defatted peony seed meal powder enzymatic hydrolyzate

[0062] Get the defatted peony seed meal powder 1000g that protein content is 50%, at first add the total 60g of alkaline protease and tyrosinase by the amount of 6% of defatted cake powder quality, alkaline protease and tyrosinase are respectively 52.5g and 7.5g, that is, the mass ratio is 7:1; add 6.7L of water to adjust the mass concentration of defatted cake powder to 15%, and adjust the pH value to 8.0 with phosphate buffer solution; react for 2 hours at a temperature of 55°C; A total of 40g of tyrosinase and flavor protease were added to the amount of 4% of the mass of the meal flour. The tyrosinase and flavor protease were 6.7g and 33.3g respectively, that is, the mass ratio was 1:5, and the pH value was adjusted to 7.0 with phosphate buffer solution. ; under ...

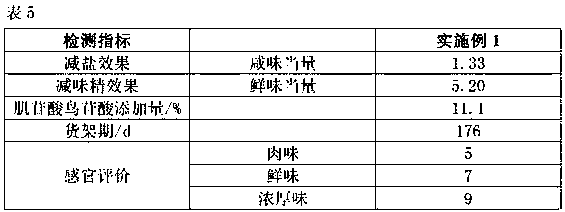

Embodiment 3

[0085] The specific production operation steps of a kind of plant source flavor-enhancing seasoning base material are as follows:

[0086] (1) Preparation of degreased walnut meal powder enzymatic hydrolyzate

[0087] Get the defatted walnut meal powder 1000g that protein content is 30%, at first add the total 50g of alkaline protease and tyrosinase by the amount of 5% of defatted cake powder quality, alkaline protease and tyrosinase are respectively 43.0g and 7.0g g, that is, the mass ratio is 6:1; add 7.7L of water to adjust the mass concentration of defatted cake powder to 13%, and adjust the pH value to 7.5 with phosphate buffer solution; react for 1.5 h at a temperature of 50 °C; Add 20g of tyrosinase and flavor protease in an amount of 2% of the powder mass, the tyrosinase and flavor protease are 4.0g and 16.0g respectively, that is, the mass ratio is 1:4, and the pH value is adjusted to 6.0 with phosphate buffer solution; The reaction time was 2.5 h at 45 °C; the enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com