Method for directionally degrading secondary deposited protein of soybean sauce

A secondary precipitation and soy sauce technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of high membrane operation cost, increased labor cost, non-targeting, etc., to improve appearance quality, save cost, and improve internal quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 crude enzyme preparation

[0025] Soybean meal powder and corn starch were used as the main medium, fully mixed with water, steamed (121°C / 20min), and then inoculated with Aspergillus niger ATCC16404 (1.0×10 6 spores / g substrate) for solid-state culture. The solid-state culture conditions are as follows: the initial culture temperature is 28°C, the relative humidity is 90%, the song is turned over at 13 hours, and the temperature is controlled at 30°C; the humidity is reduced to promote the secretion of the target protease when the culture reaches 45 hours; When the amount of secretion reaches the maximum value, the preparation of the enzyme preparation is completed, and the above-mentioned koji is collected to obtain the crude enzyme preparation.

Embodiment 2

[0026] Embodiment 2 high salt dilute state method

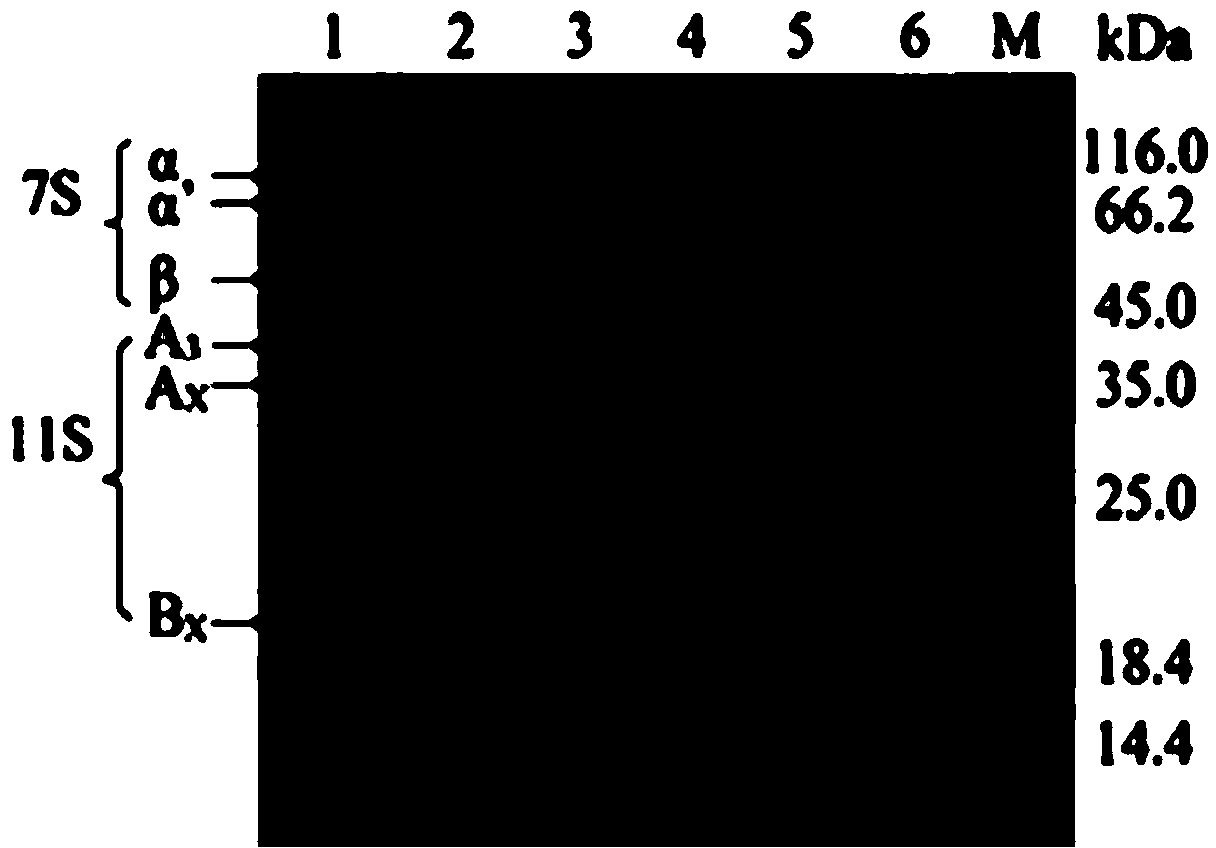

[0027] After Daqu (soybean, soybean meal, flour, roasted wheat) enters the pond or falls into the tank, keep the salt concentration in the mash at 6%, ferment with low salt for 10 days, add the enzyme preparation prepared in Example 1, and the enzyme preparation addition amount is 3000IU / g substrate protein, continue low-salt fermentation for 6 days. Salt is added to the mash in an amount to make the salt content of the mash reach 20% (w / w), and the fermentation is continued for 5 months. After the mash was filtered through filter paper, the SDS-PAGE electrophoresis method was used to measure the degradation of soy sauce secondary precipitation protein in the fermentation broth. At the same time, the filtered mash was pasteurized and packaged, and stored at room temperature for 3 months to observe the formation of secondary precipitation. SDS-PAGE electrophoresis experiment result proves that its secondary precipitation pro...

Embodiment 3

[0029] Embodiment 3 low-salt solid-state method

[0030] After Daqu (soybean meal, soybean, flour, bran) enters the pond or falls into the tank, keep the salt concentration in the mash at 5%, ferment at 42-45°C, and ferment with low salt for 4 days, add the enzyme preparation prepared in Example 1, enzyme The addition amount of the preparation is 5000IU / g substrate protein, and the low-salt fermentation is continued for 5 days. Salt is added to the mash in an amount to make the salt content of the mash reach 14% (w / w), and the fermentation is continued for 1 month. After the mash was filtered through filter paper, the SDS-PAGE electrophoresis method was used to measure the degradation of soy sauce secondary precipitation protein in the fermentation broth. At the same time, the filtered mash was pasteurized and packaged, and stored at room temperature for 3 months to observe the formation of secondary precipitation. SDS-PAGE electrophoresis experiment result proves that its seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com