High-pressure electrification detergent

A technology of high-voltage electrification and cleaning agent, applied in the field of cleaning agents, can solve the problems of trouble, high cost, affecting production and life, etc., and achieve the effects of convenient use, simple formula, and great economic and social significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

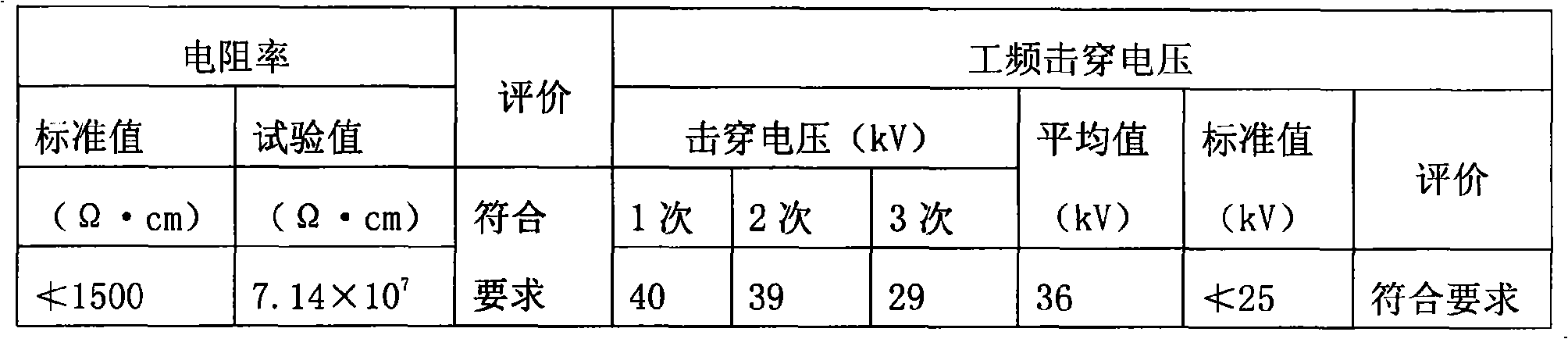

Image

Examples

Embodiment 1

[0011] Embodiment 1: the present invention is preferably made of 45% of transformer oil measured by weight percentage, 45% of naphtha, 9% of light solvent oil and 1% of penetrating agent in practice, and the above-mentioned raw materials are loaded into a stainless steel stirring tank simultaneously , stirred at 15°C and 1 atmosphere for 2 hours;

Embodiment 2

[0012] Embodiment 2: prepare 100kg high-voltage charged cleaning agent, its component is: 10# transformer oil 45kg, naphtha 45kg, light solvent oil 9kg and penetrating agent 1kg, its component is packed into stainless steel stirring tank together, at 20 ℃ , Under 1 atmospheric pressure, stir for 1.5 hours;

[0013] The transformer oil is preferably 10# transformer oil; the light solvent oil is preferably 120# light solvent oil, and the penetrating agent is ethyl silicone oil.

[0014] The use method of the cleaning agent of the present invention: professional technicians use special insulating spray guns and testing instruments, and follow the live working regulations of the electric power industry to carry out high-voltage live cleaning, which is simple, fast and effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com