Direct-buried gate valve

A technology of gate valve and direct burial, applied in sliding valves, valve details, valve devices, etc., can solve the problems of large shape, leakage, troubles, etc., reduce the possibility of corrosion, solve unreliability, and reduce leakage points Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

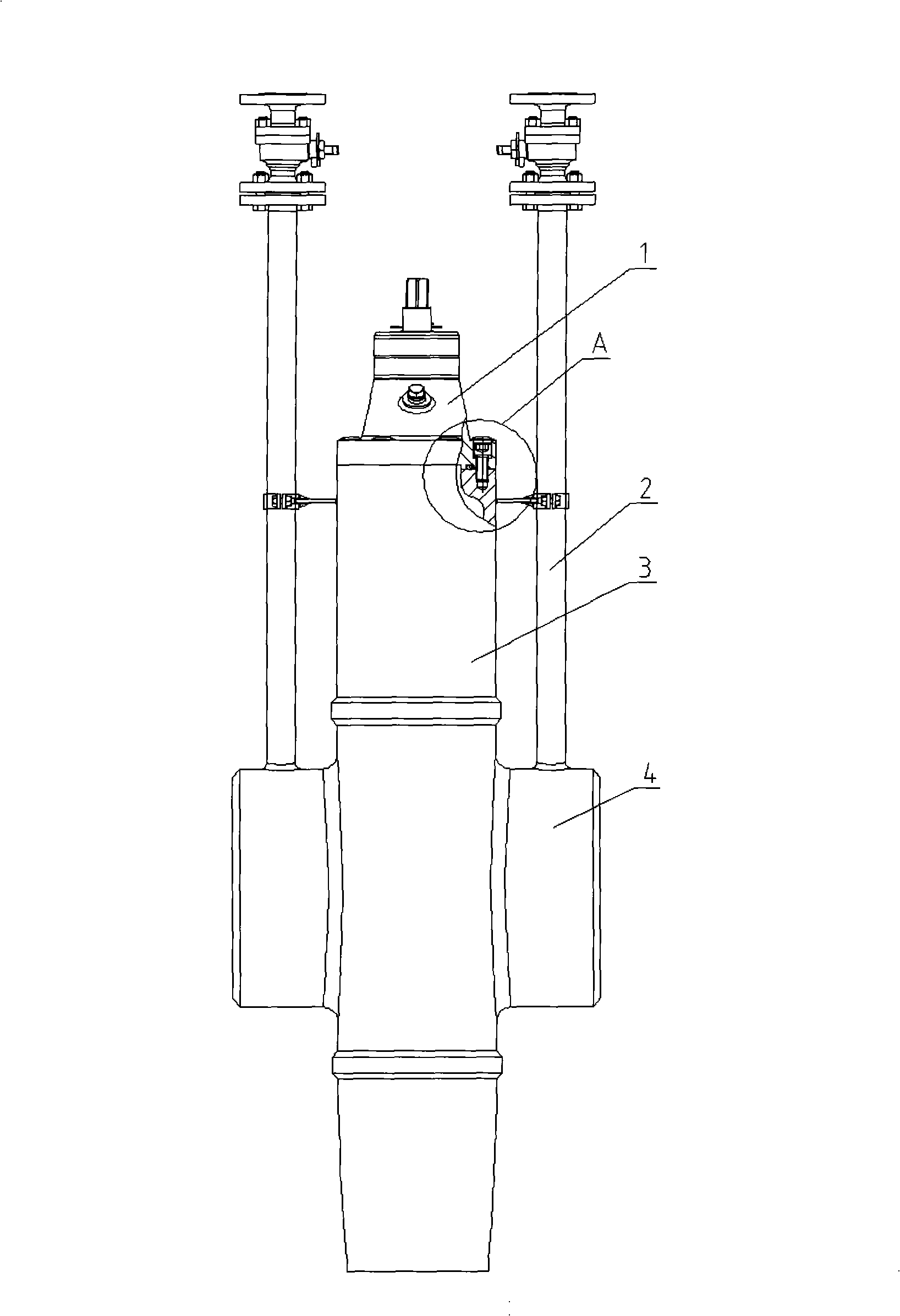

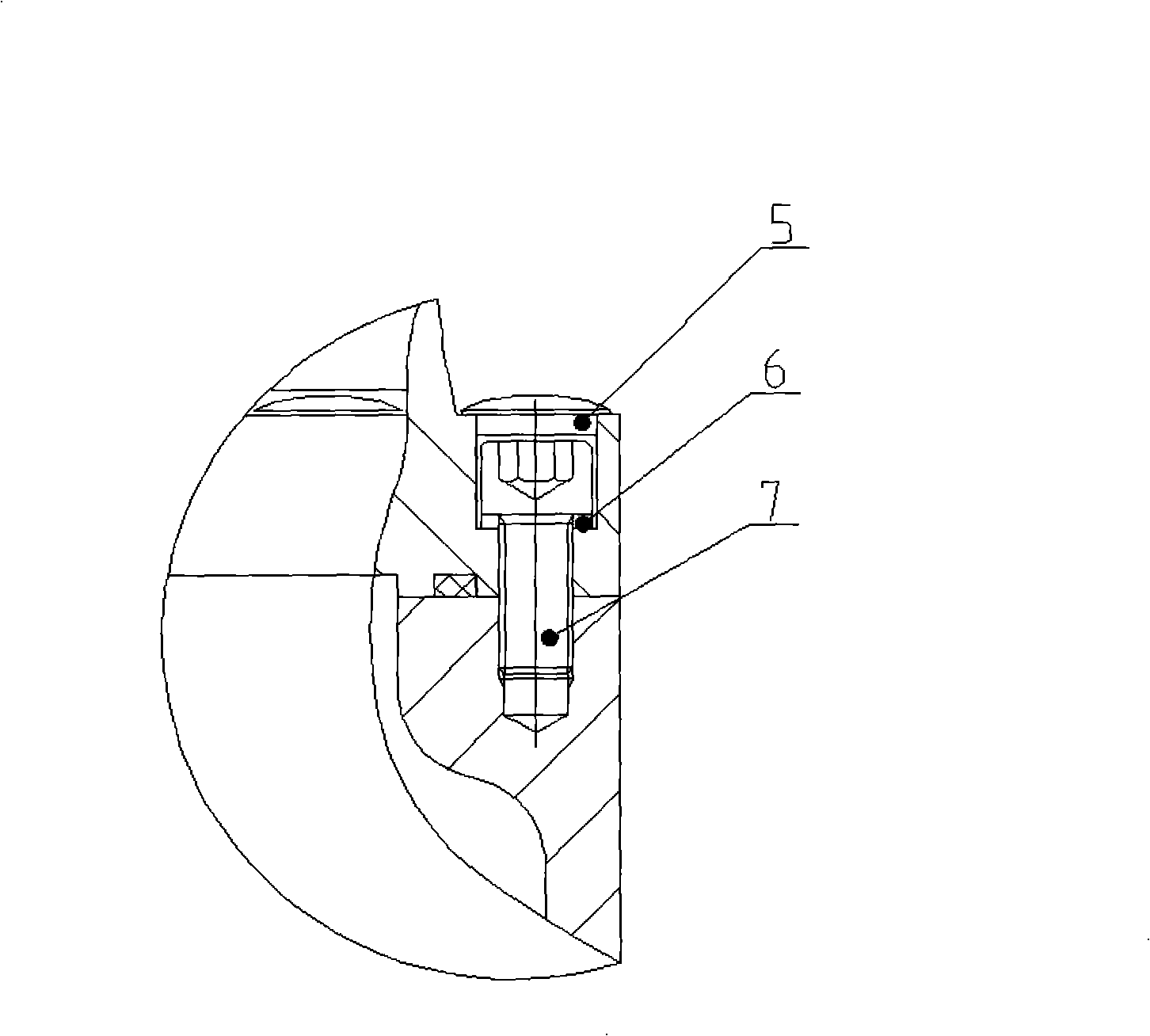

[0014] The invention discloses a novel directly buried gate valve. Such as figure 1 , figure 2 As shown, it includes a valve body 3 and a valve cover 1 connected to each other, and the valve body 3 is provided with a valve body interface 4 . The valve cover 1 is provided with a counterbore, and a fastener is placed in the counterbore to connect the valve body and the valve cover together. In this preferred embodiment, the said fastener is a screw 7, and a spring washer 6 is set on the screw 7. The head of the screw 7 is lower than the outer surface of the valve cover 1 , that is to ensure that the screw 7 is not exposed outside the valve cover 1 . And, the end of the counterbore of described bonnet 1 is also provided with a rubber cap 5, and the shape of rubber cap 5 just can block the opening of counterbore, is that screw 7 can't be contacted with the outside world, has reduced screw 7 possibility of being corroded.

[0015] In addition, two discharge pipes 2 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com