Air conditioner heat exchange type condensator and spray evaporative cooling system

A heat exchanger, evaporative cooling technology, applied in evaporator/condenser, steam/vapor condenser, indirect heat exchanger, etc., can solve the problems of high energy consumption of air conditioning, difficulty in cooling and heating, and reduce energy consumption , prolong life, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

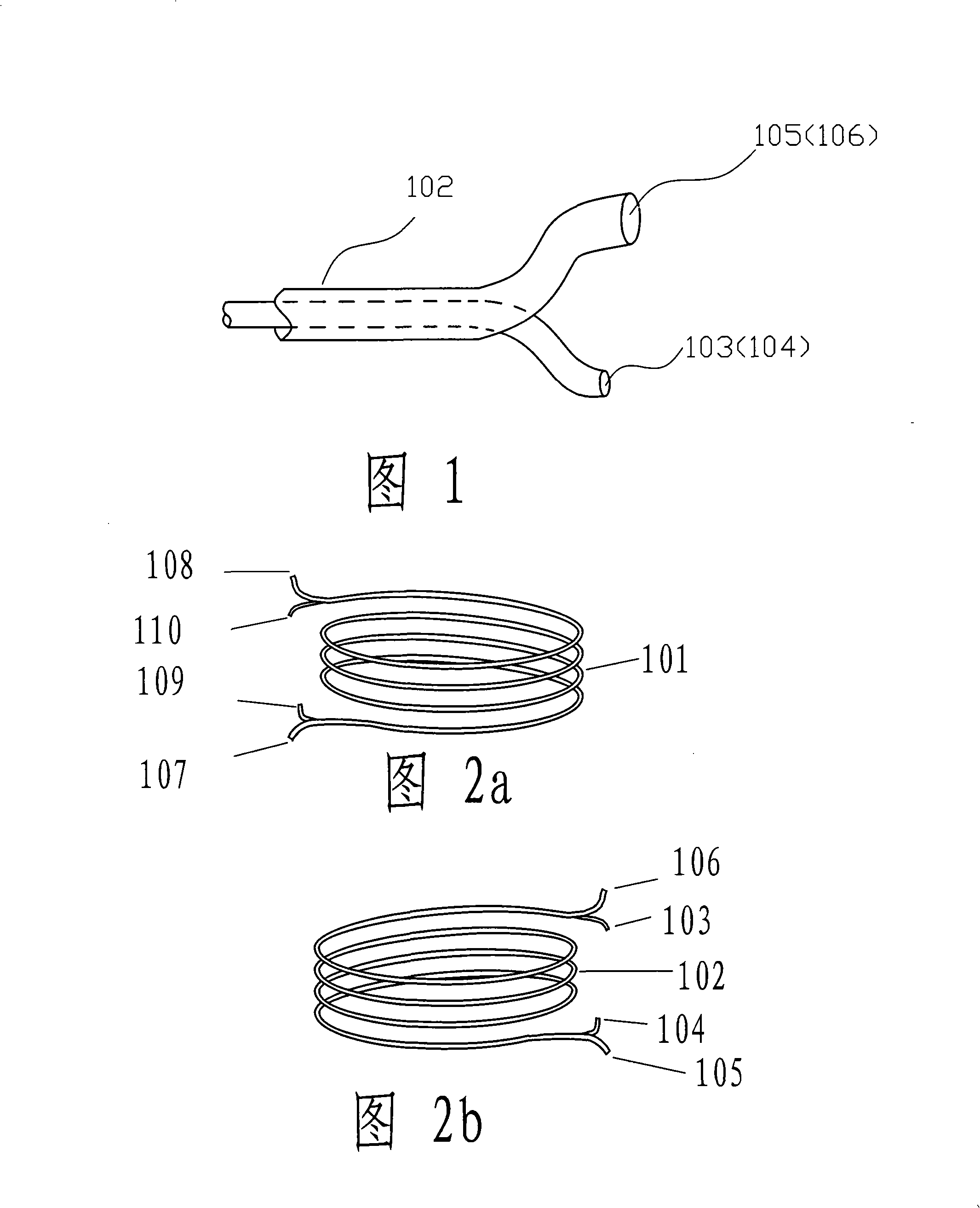

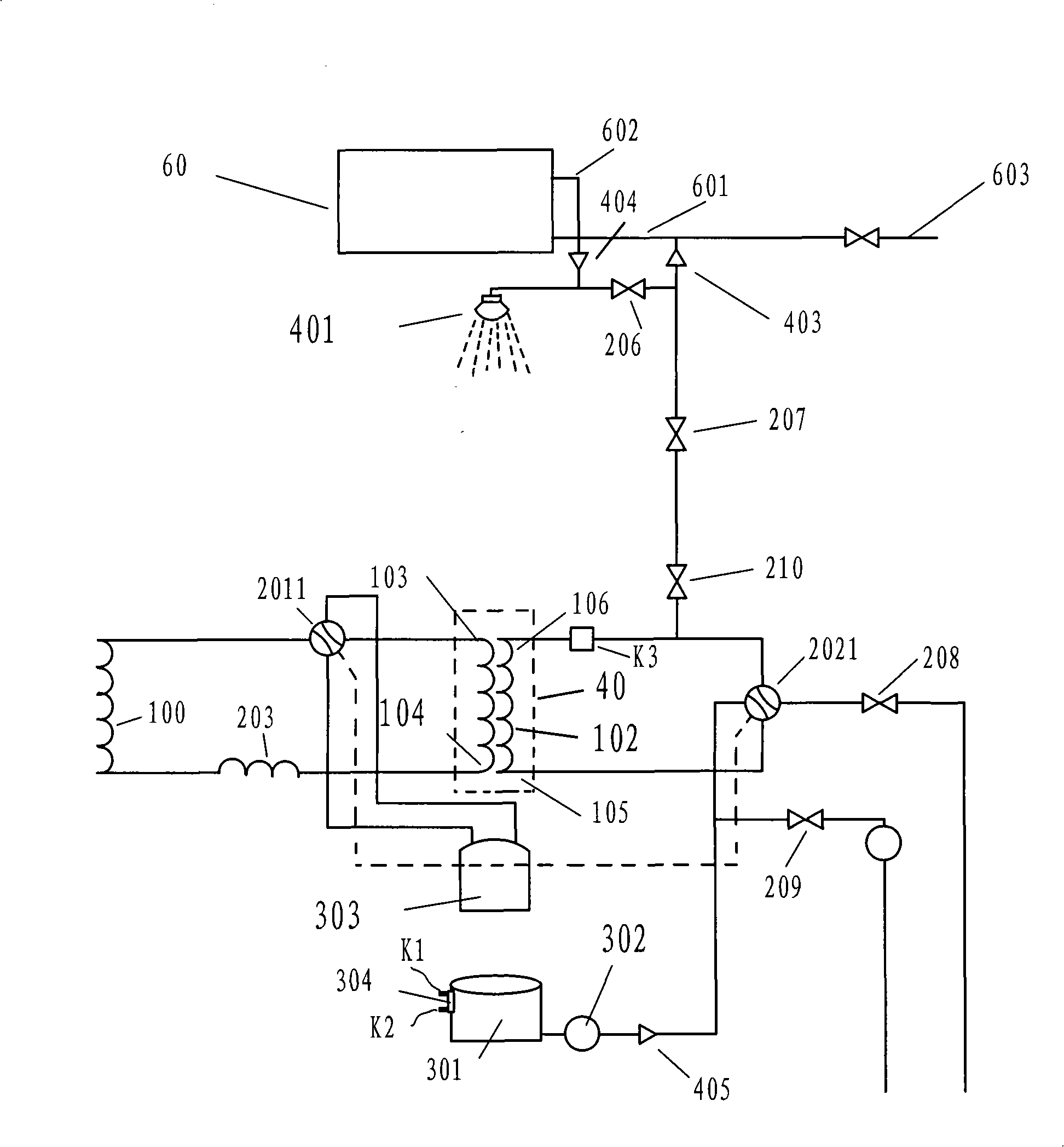

[0047] This embodiment air conditioning heat exchange condenser and spray evaporative cooling system are suitable for refrigeration air conditioning, see Fig. 1, Fig. 2, image 3 As shown, the system includes a heat exchanger, a spray evaporative cooler, a water accumulator, a hot water tank, and a water supply system. The second heat exchanger 102 is a double-layer spiral copper tube; the compressor 303 passes through the first four-way valve 2011 is connected to the upper port 103 of the inner layer copper tube of the second heat exchanger 102, and the lower port 104 of the inner layer copper tube of the second heat exchanger 102 passes through the dryer to the capillary tube 203, and is connected to the evaporator 100 through a pipeline, and the evaporator 100 It is connected to the compressor 303 through the first four-way valve 2011 through pipelines.

[0048] The water accumulator 301 is arranged at the lower part of the compressor 303, and the compressor 303 is accommoda...

no. 2 Embodiment

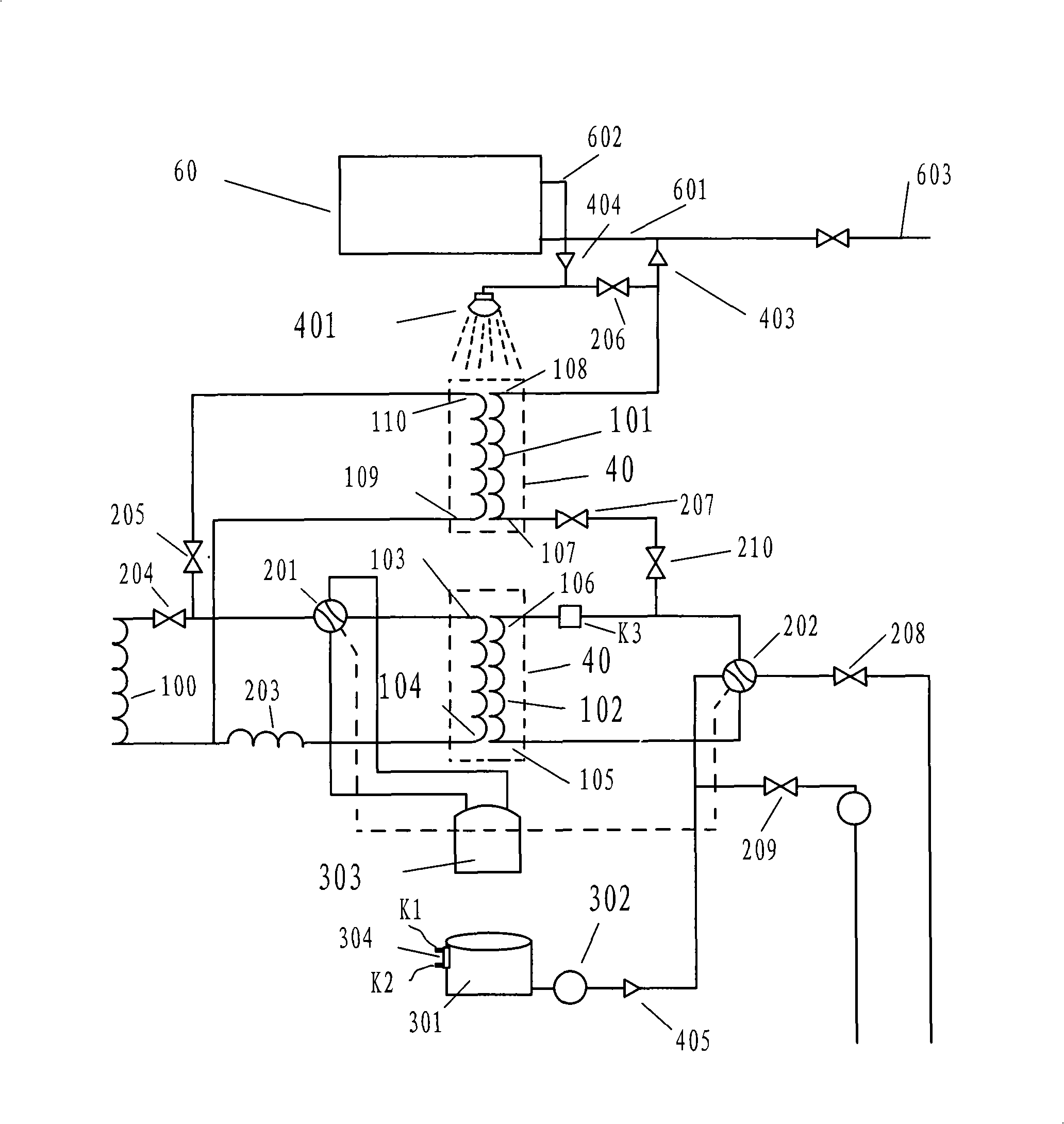

[0055] The air-conditioning heat exchange condenser and spray evaporative cooling system of this embodiment are suitable for heating and cooling air-conditioning, and can be used for making hot water, as shown in FIGS. 1 , 2 , and 4 . An air-conditioning heat exchange condenser spray evaporative cooling system, including a heat exchanger, a spray evaporative cooler, a water accumulator, a hot water tank and a water supply system. The upper port 103 of the inner layer copper tube of the second heat exchanger 102 is connected to each other, and the lower port 104 of the second heat exchanger 102 inner layer copper tube passes through the drier to the capillary tube 203, and is connected with the evaporator 100 through a pipeline, and the evaporator 100 is connected through a two-way electromagnetic The valve 204, the first four-way two-way switching valve 201 and the compressor 303 are connected through pipelines;

[0056] In the second embodiment, the water accumulator 301 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com