Ceramic kiln temperature checking method based on optical fibre grating sensing

A ceramic kiln, fiber grating technology, applied in the field of sensing and detection, can solve the problems of inability to realize the conversion of temperature signal and electrical signal, the influence of temperature distribution, poor dynamic characteristics, etc., to achieve health monitoring, good stability, good The effect of dynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

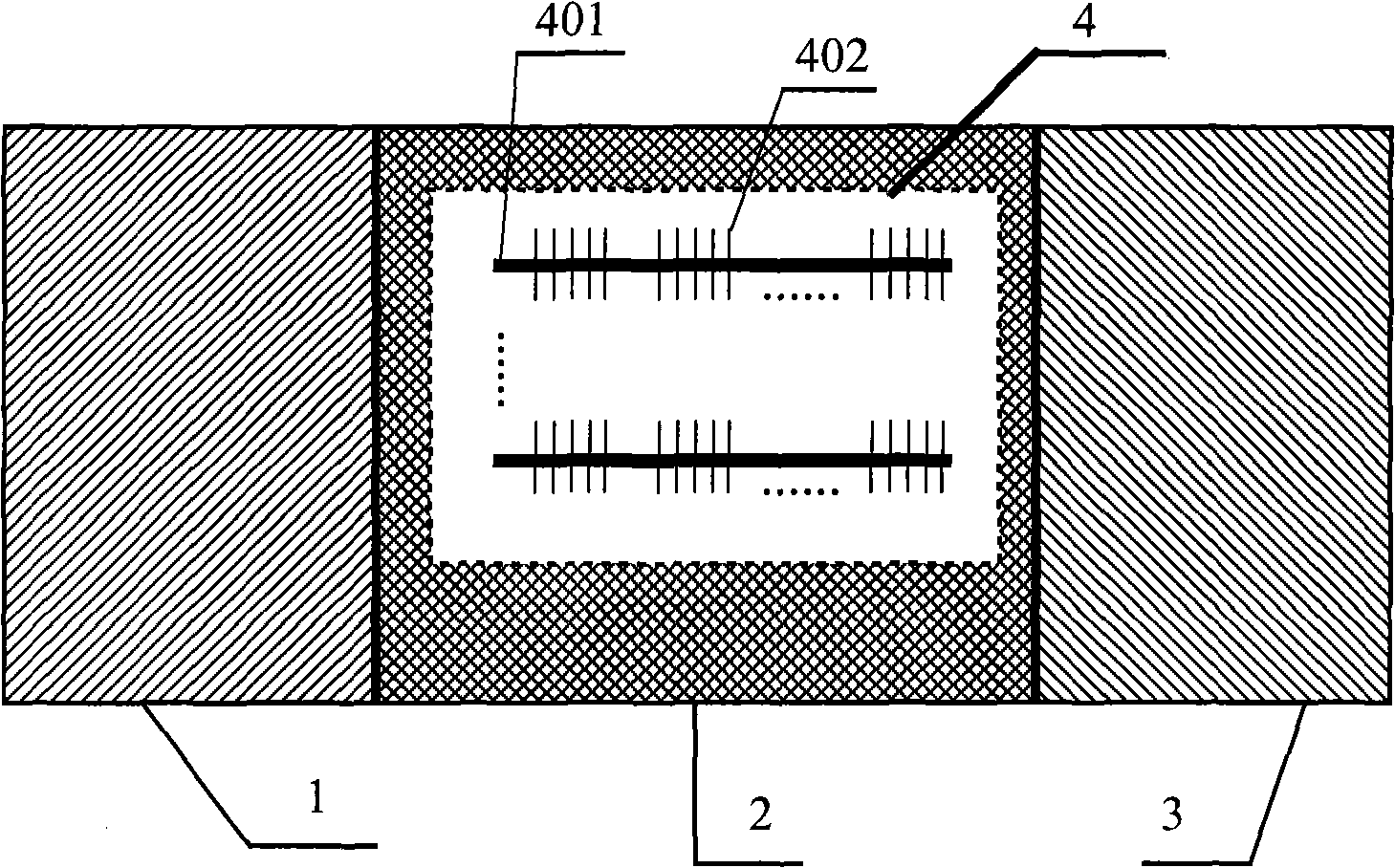

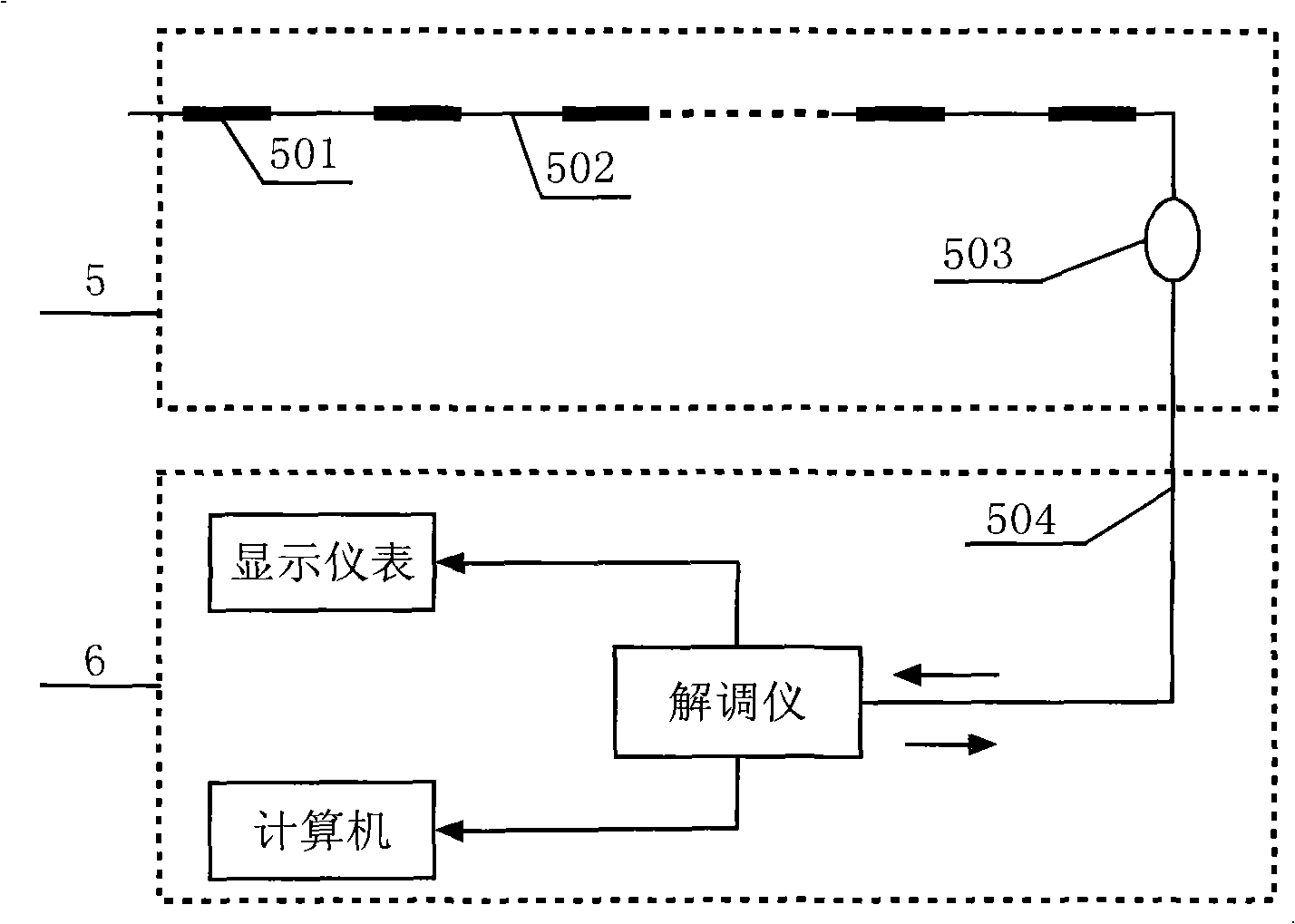

[0015] The method for detecting the temperature of the ceramic kiln provided by the invention is to use the optical fiber grating sensing technology to detect the temperature of the ceramic kiln. Specifically: optical fibers are placed on the two outer sides and the outer top of the ceramic kiln body, and multiple gratings are connected in series in each optical fiber to form a fiber grating sensor network for distributed measurement of the kiln temperature.

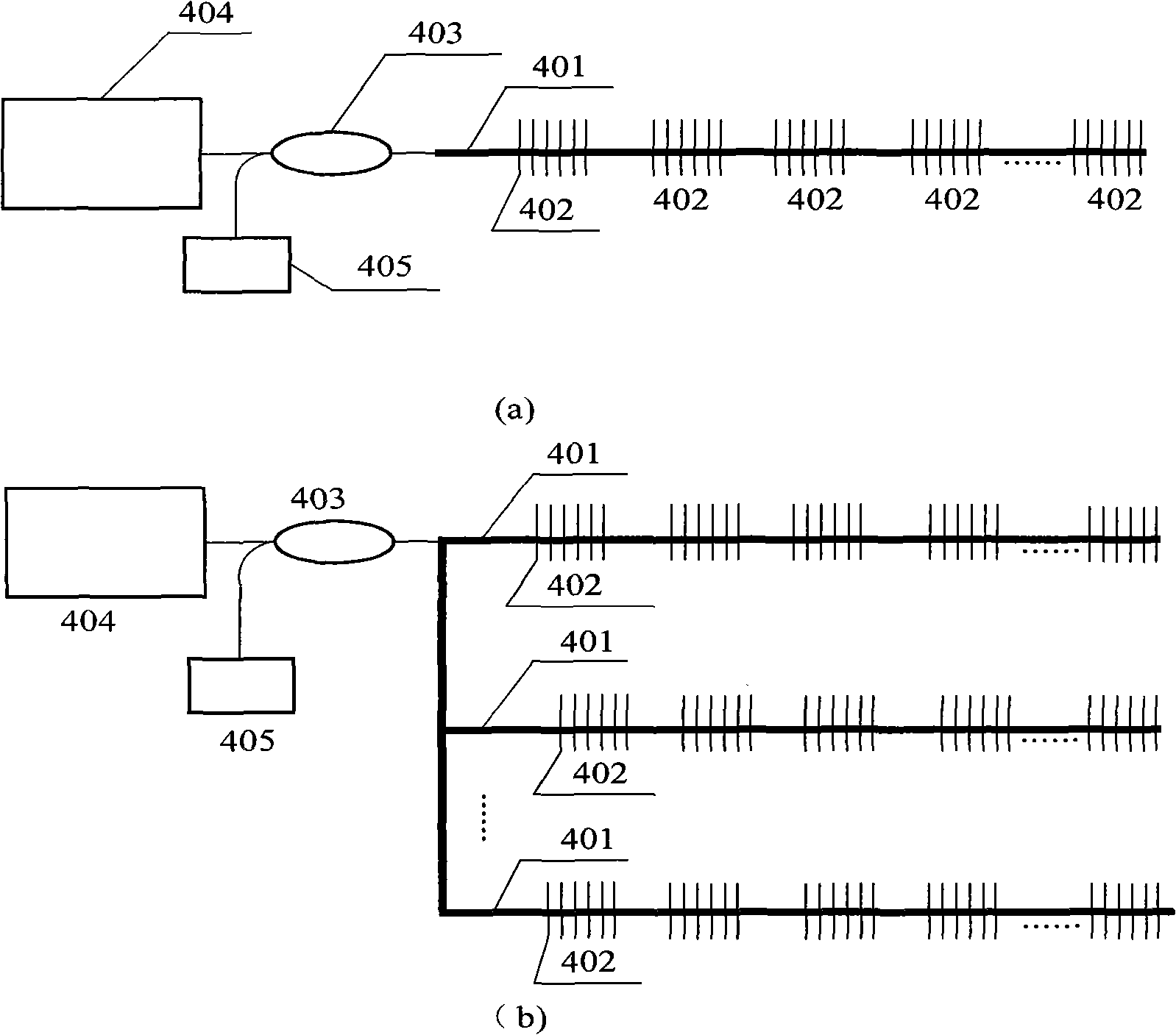

[0016] The fiber grating sensing network has a structure such as figure 1 As shown: the firing zone 2 of the kiln is connected with the preheating zone 1 and the cooling zone 3 of the kiln. The fiber grating network 4 is used to measure the temperature of the firing zone of the kiln, and is respectively attached to the two outer sides and the outer top of the furnace body of the firing zone of the kiln. Fiber Bragg grating network 4 is a network system composed of fiber Bragg grating sensors using a distributed network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com