Optical diffusion thin film and LCD device using the optical diffusion thin film

A liquid crystal display device and optical diffusion technology, applied in the field of optical diffusion film and liquid crystal display device, can solve the problems of reduced brightness gain, low brightness, large gap, etc., achieve high optical uniformity and brightness, reduce light source loss, The effect of reducing the number of combined components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

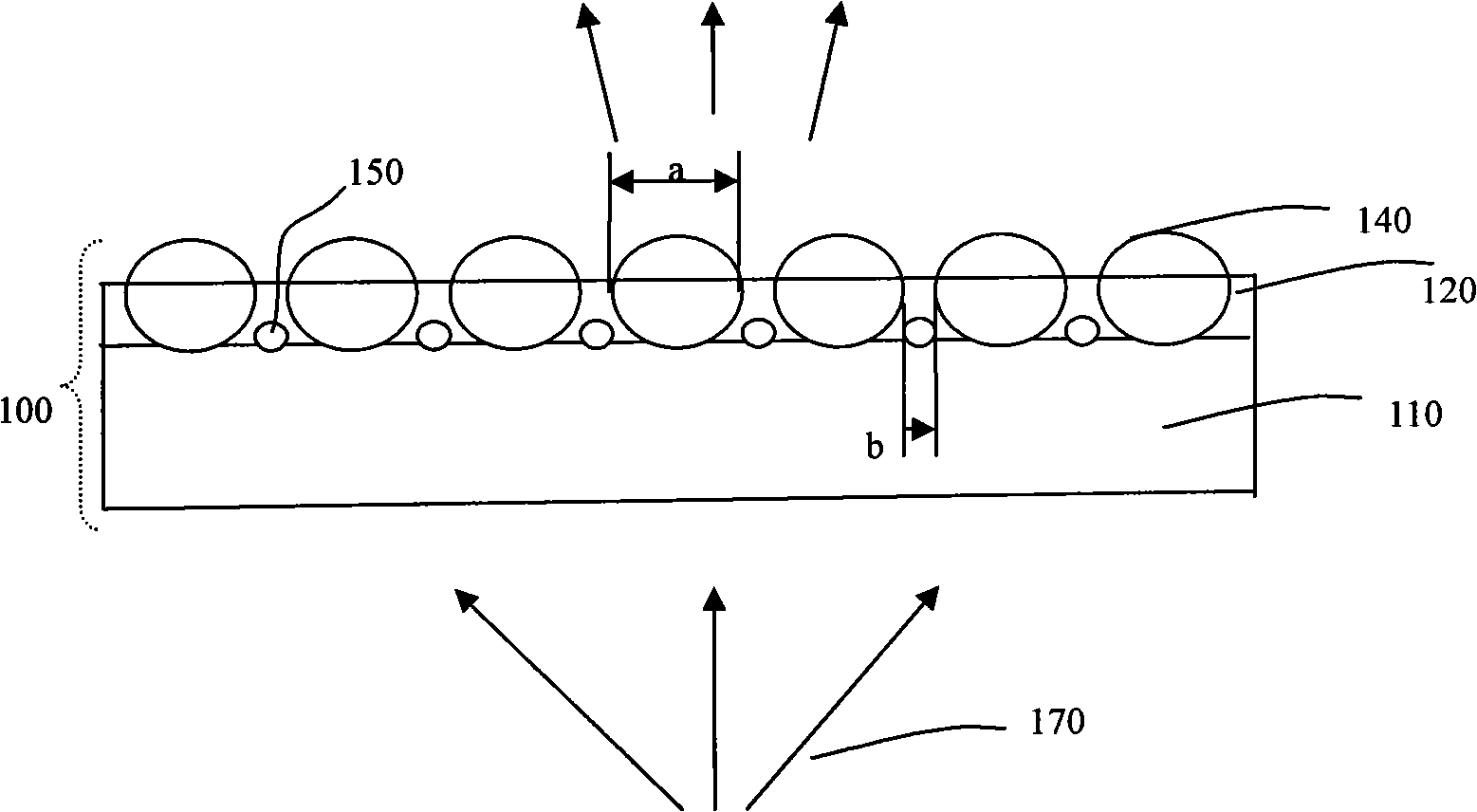

[0023] Such as figure 1 As shown, an optical diffusion film, the optical diffusion film 100 mainly includes a transparent substrate 110, the upper surface of the transparent substrate 110 is provided with an upper diffusion coating 120, the upper diffusion coating 120 is provided with upper diffusion particles, and the upper diffusion coating 120 is provided with upper diffusion particles. The diffusion particles are distributed on the upper surface of the transparent substrate 110 , and the upper diffusion particles include large particles 140 with a spherical structure and small particles 150 with a spherical structure. In this specific embodiment, the maximum geometric dimension of the large particle 140 can be in the range of 1-100 microns. When the large particle 140 is larger, that is, when the maximum geometric dimension is greater than 100 microns, the coating process will be more difficult, and when the large particle 140 is larger than 100 microns, the coating proces...

Embodiment 2

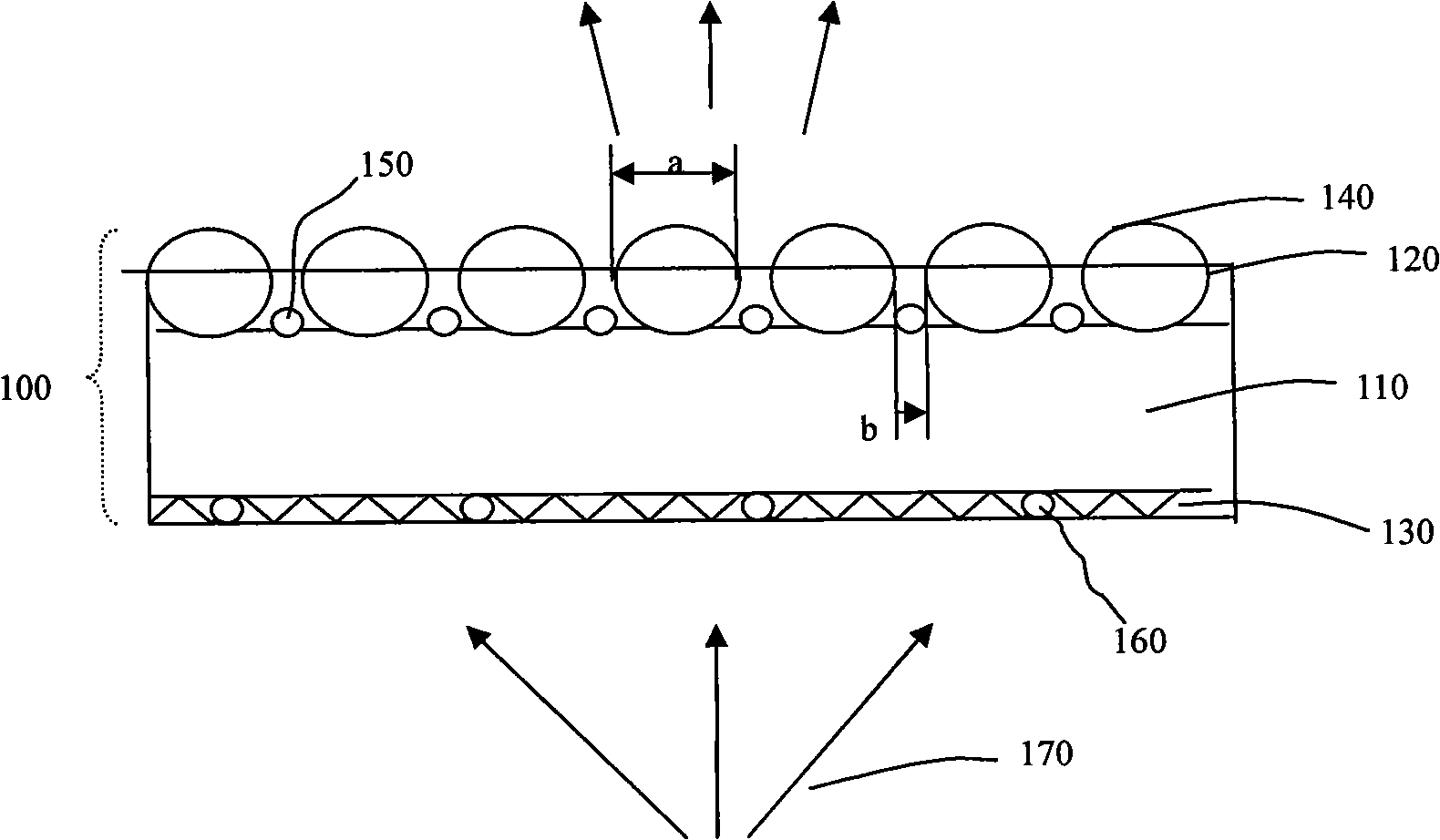

[0027] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that an anti-adhesive coating 130 with a textured structure is provided on the lower surface of the transparent substrate 110 of this embodiment, and the anti-adhesive coating Spherical anti-adhesion particles 160 are arranged inside 130 , and the particle size of the anti-adhesion particles 160 is slightly larger than the thickness of the anti-adhesion coating 130 after film formation. The geometric size of the anti-adhesion particles 160 is relatively small, and in this embodiment the particle diameter of the anti-adhesion particles is about 5 microns, and they are arranged on the lower surface of the transparent substrate 110 by randomly scattered and sparsely non-contact, so that the optical When the diffusion film 100 is specifically applied in a backlight module, a thin air layer is formed between other components. The ratio of the su...

Embodiment 3

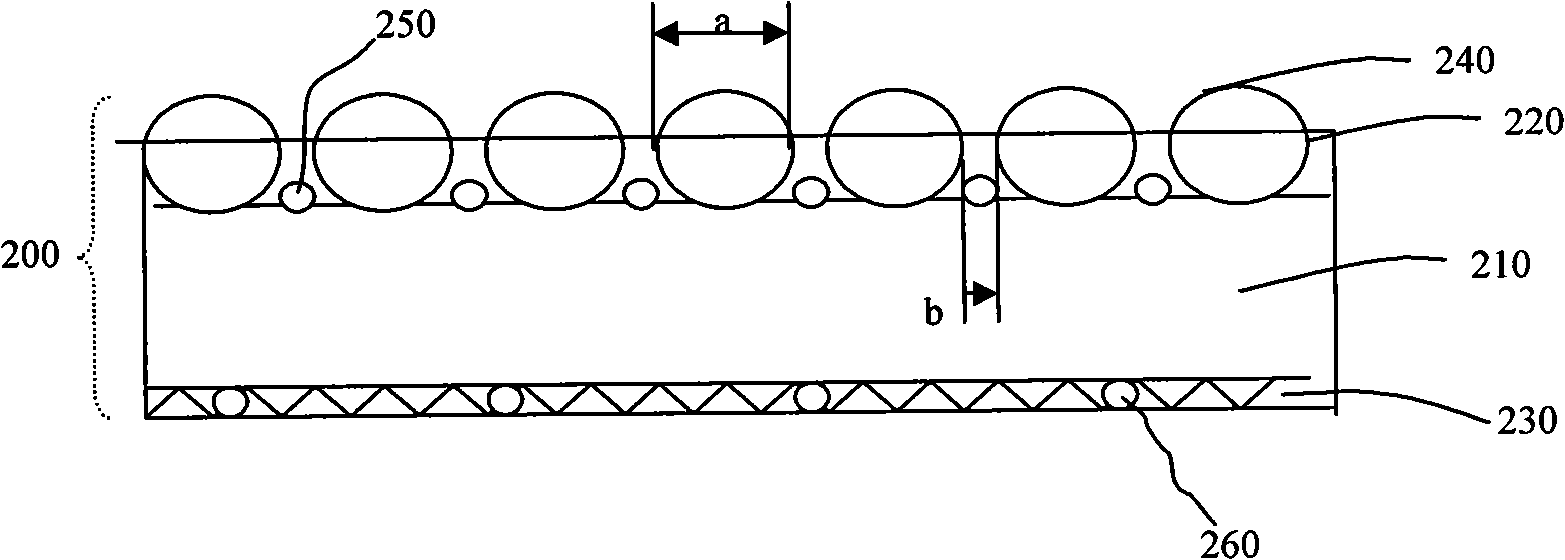

[0029] Such as image 3As shown, the optical diffusion film 200 of this embodiment also includes a transparent substrate 210, an upper diffusion coating 220 containing large spherical particles 240 and small spherical particles 250, and an anti-adhesive particle 260 with a textured structure. Anti-stick coating 230. and figure 2 The difference of the shown embodiment two is that the particle diameter of the large particle 240 in this embodiment is 10 microns, the particle diameter of the small particle 250 is 5 microns, and the particle diameter ratio of the large particle 240 and the small particle 250 is 2:1 , this optical diffusion film 200 (mixed use of large and small particles) is compared with the optical diffusion film using large particles (particle diameter is 10 microns) for haze and brightness. As can be seen from Table 1, the optical diffusion film of the present embodiment The film 200 can change the atomization effect of the upper diffusion coating 220 and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap