Bidirectional geared motor

A bidirectional gear and motor technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as difficult assembly, poor end face sealing, and low volumetric efficiency, and improve work reliability , prolong the service life and reduce the effect of overlapping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

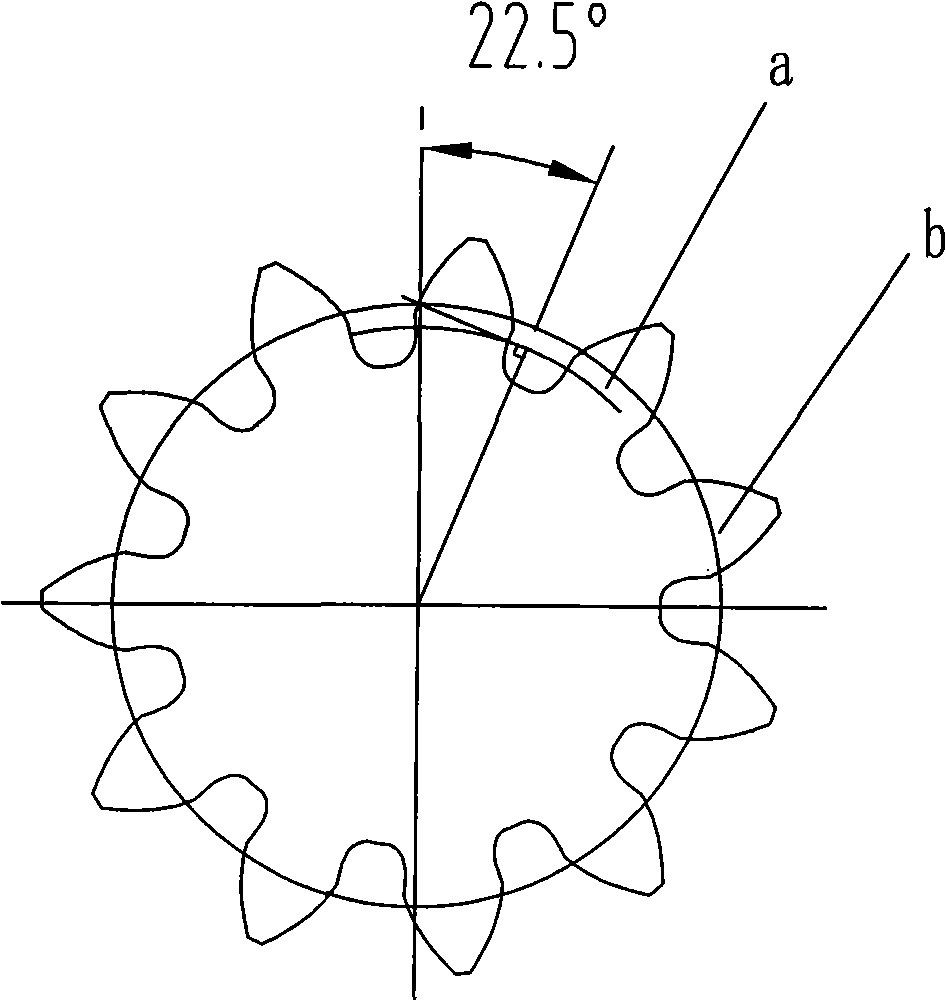

[0031] figure 1 As shown, the transmission gear set in this embodiment is: pressure angle 22.5°, center distance 31.3mm, 2.75 modulus 11 teeth, figure 1 Among them, a is the base circle, and b is the index circle.

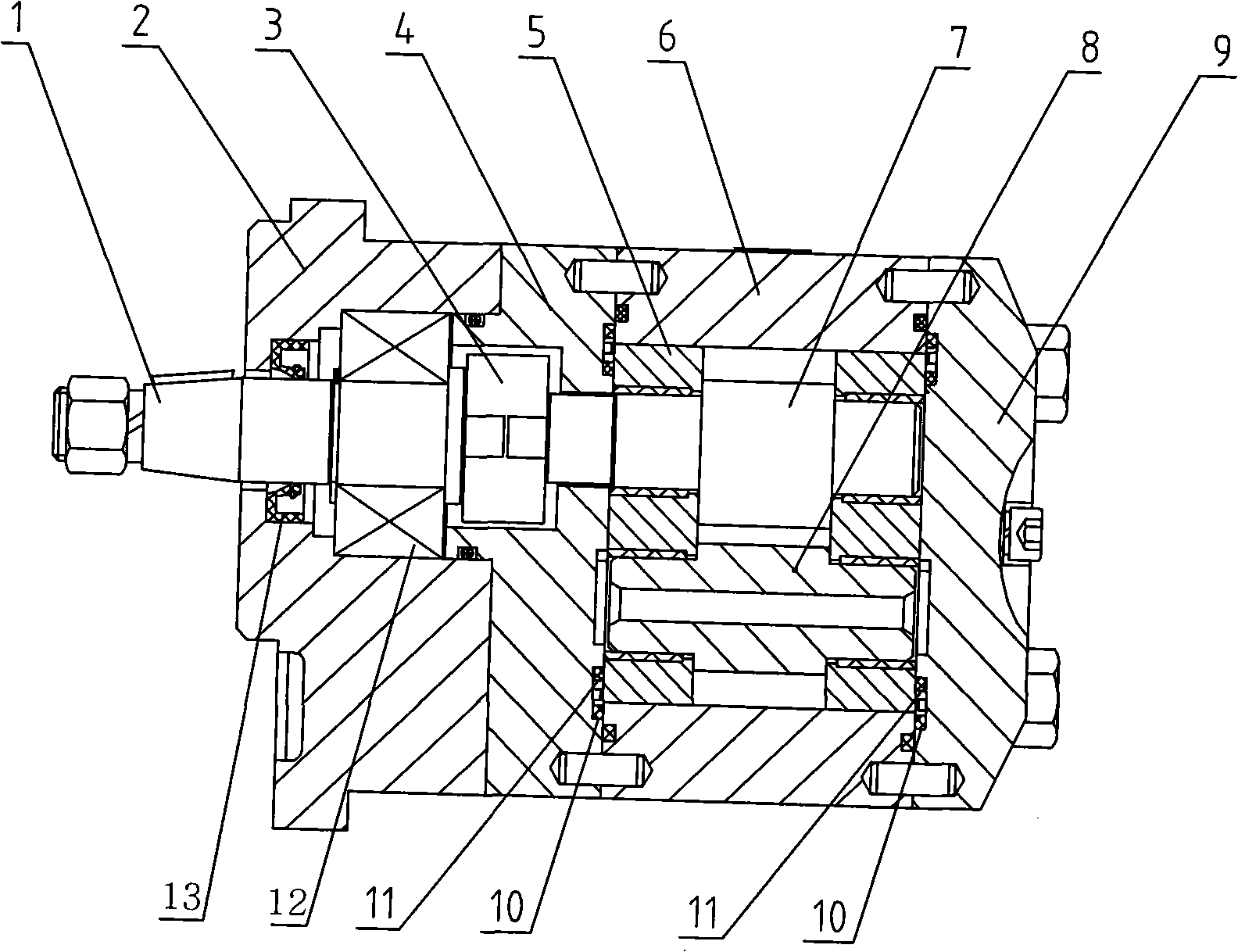

[0032] The outer casing is arranged in four sections along the axial direction, which are the front cover 2, the transition cover 4, the casing 6 and the rear cover 9 in sequence;

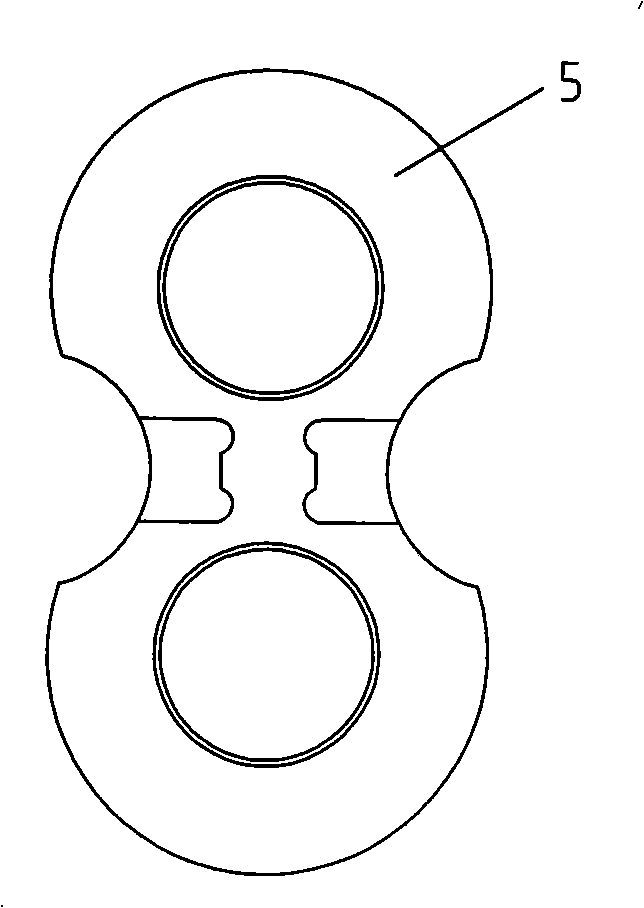

[0033] The overall shaft sleeve 5 between the driving shaft and the driven shaft is arranged in the shape of "8";

[0034] The joint surface between the transition cover 4 and the housing 6 and between the back cover 9 and the housing 6 is an integral sealing groove, and the integral sealing groove is formed between the outer ring groove and the inner ring "dumbbell" groove with a diameter of It is connected to the straight groove, and corresponding to the integral sealing groove, a fully symmetrical integral high-temperature-resistant seal is provided, including a sealing ring 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com