Bi-stable magnetic clutch

A magnetic clutch and bistable technology, applied in the field of clutches, can solve the problems of electromagnetic coils being easily damaged by heat, polluting the environment, and energy consumption, and achieve the effects of small electromagnetic pollution, wide application, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

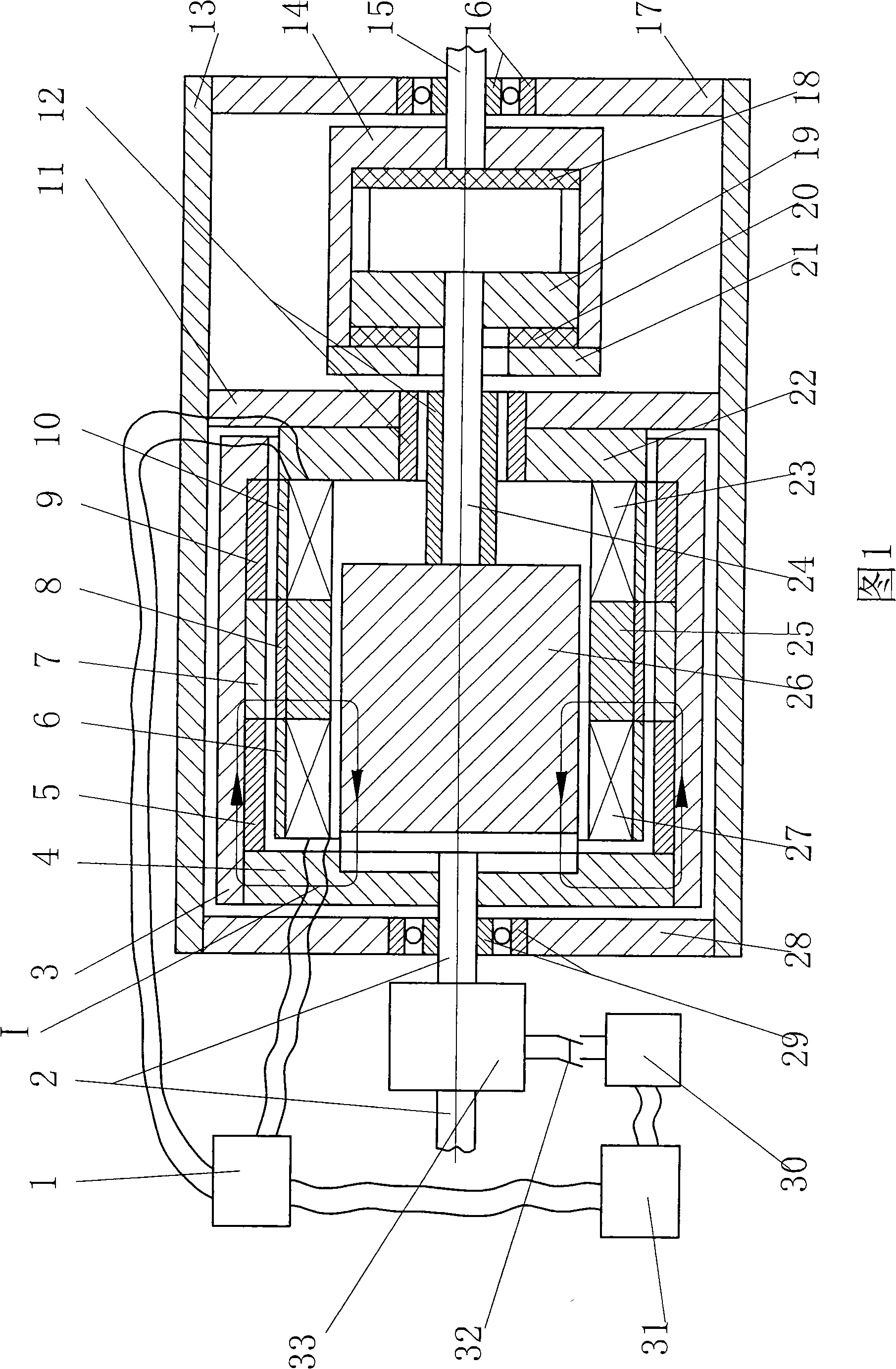

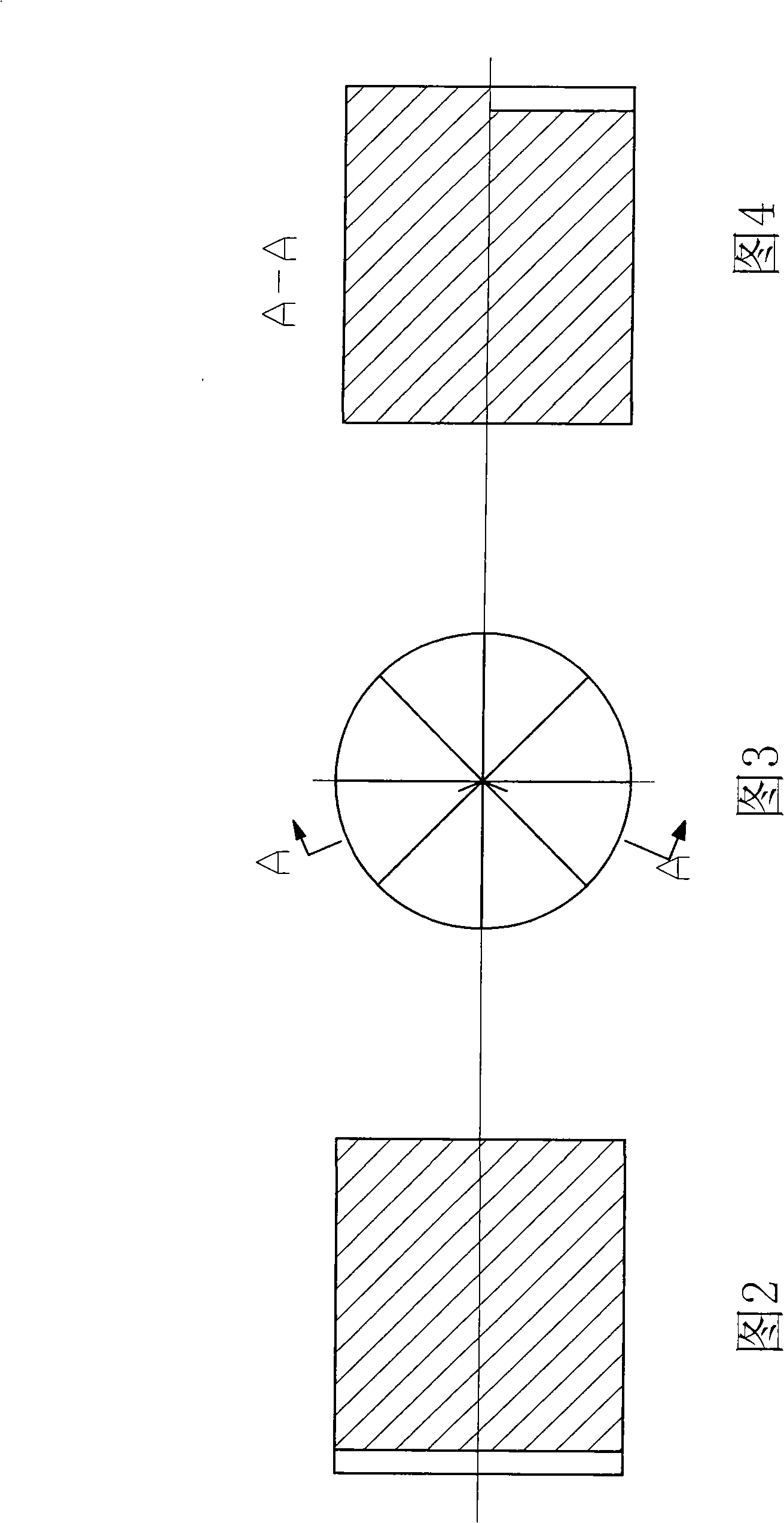

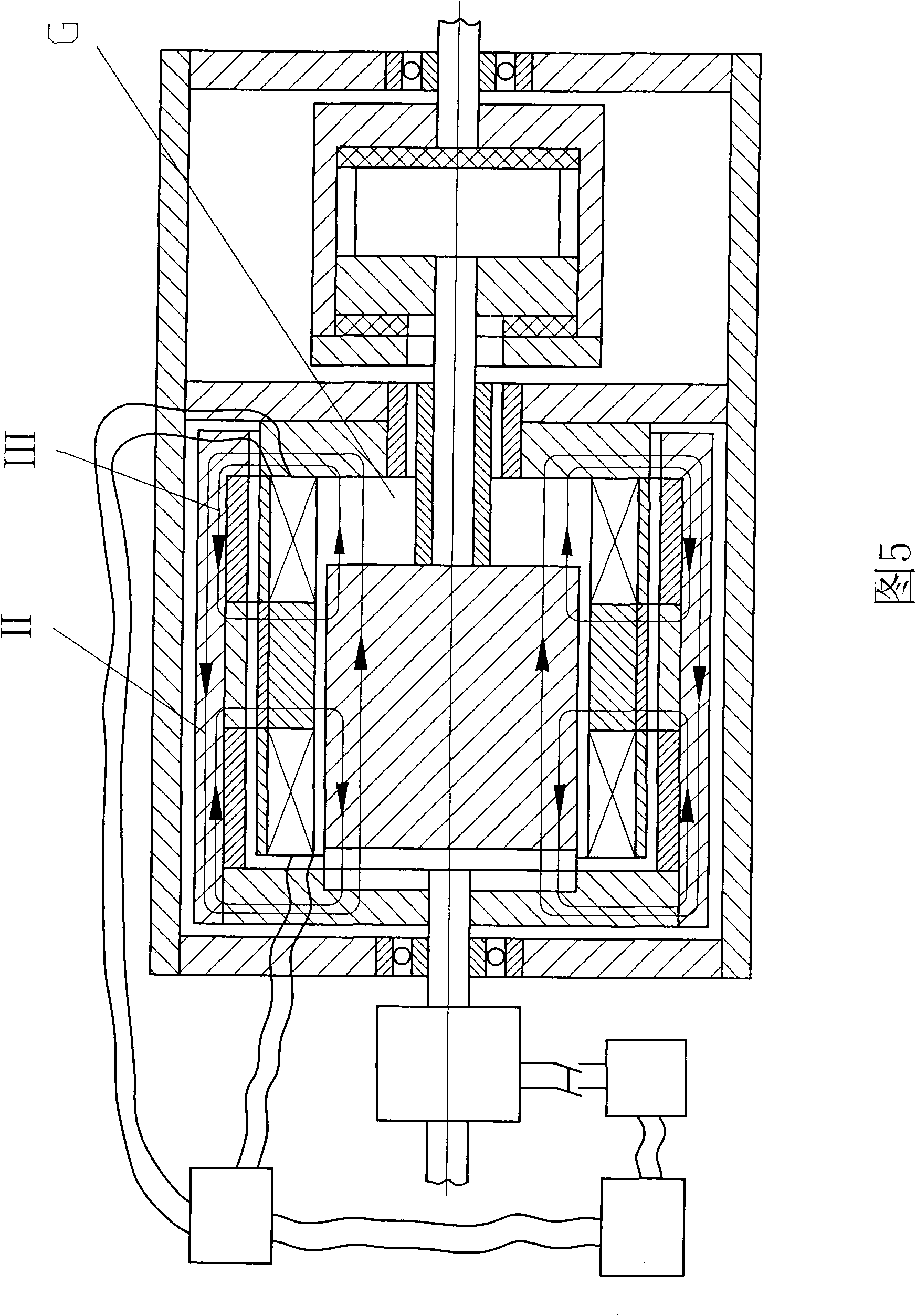

[0026] Embodiment 1: as shown in Figure 1 to Figure 4. The invention is composed of a driving wheel, a driven wheel, a stator, a brake and a control system. The driving wheel is made up of a magnet core 26, a spline stub 19, an inner spline sleeve 14 slidingly fitted with the spline stub 19, a buffer pad 18 and 20, an end plate 21, a drive shaft 15 and a shaft 24, and the magnet guide The core 26 and the spline short column 19 are coaxially consolidated with the shaft 24, the left end surface of the magnetic conductor core 26 is evenly distributed with fan-shaped teeth, the buffer pads 18 and 20 and the end plate 21 are connected with the inner spline sleeve 14, and the inner spline sleeve The cylinder 14 is connected with the drive shaft 15 and consolidated; the driven wheel is formed by the consolidation of the driven shaft 2, the magnetic conduction cylinder 3, the conduction disc 4, the non-magnetic rings 5 and 9 and the radially magnetized permanent magnet ring 7, and t...

Embodiment 2

[0028] Embodiment 2: as shown in FIG. 7 . For the clutch described in embodiment one, the non-magnetic rings 5 and 9 are removed, and the combination of the magnetic-conducting cylinder 3 and the permanent-magnetic ring 7 is changed into the magnetic-conducting cylinder 34. Its shape and size are the same as the former, and the others remain unchanged. Under the condition of meeting the performance requirements of the clutch, this can simplify the structure, reduce the cost, and improve the high temperature adaptability of the driven wheel. Fig. 7 is a schematic diagram of the combined state of this embodiment, and Fig. 8 is a schematic diagram of the detached state of this embodiment. The dotted lines V and VI in the figure show the path of the permanent magnetic flux.

Embodiment 3

[0029] Embodiment three: as shown in FIG. 9 . For the clutch described in Embodiment 1, only the permanent magnet ring 25 and the magnetic permeable ring 8 are changed to the magnetic permeable cylinder 35, which can simplify the structure, reduce the cost and improve the high temperature adaptability of the stator under the condition of meeting the performance requirements of the clutch. Fig. 9 is a schematic diagram of the combined state of this embodiment, and Fig. 10 is a schematic diagram of the detached state of this embodiment. The dotted lines VII and VIII in the figure are schematic diagrams of the paths of the permanent magnetic flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com