Articulated tank truck frame

A tank-carrying and articulated technology, which is applied to the frame field of an articulated tanker, can solve the problems of potential safety hazards, inflexible steering, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

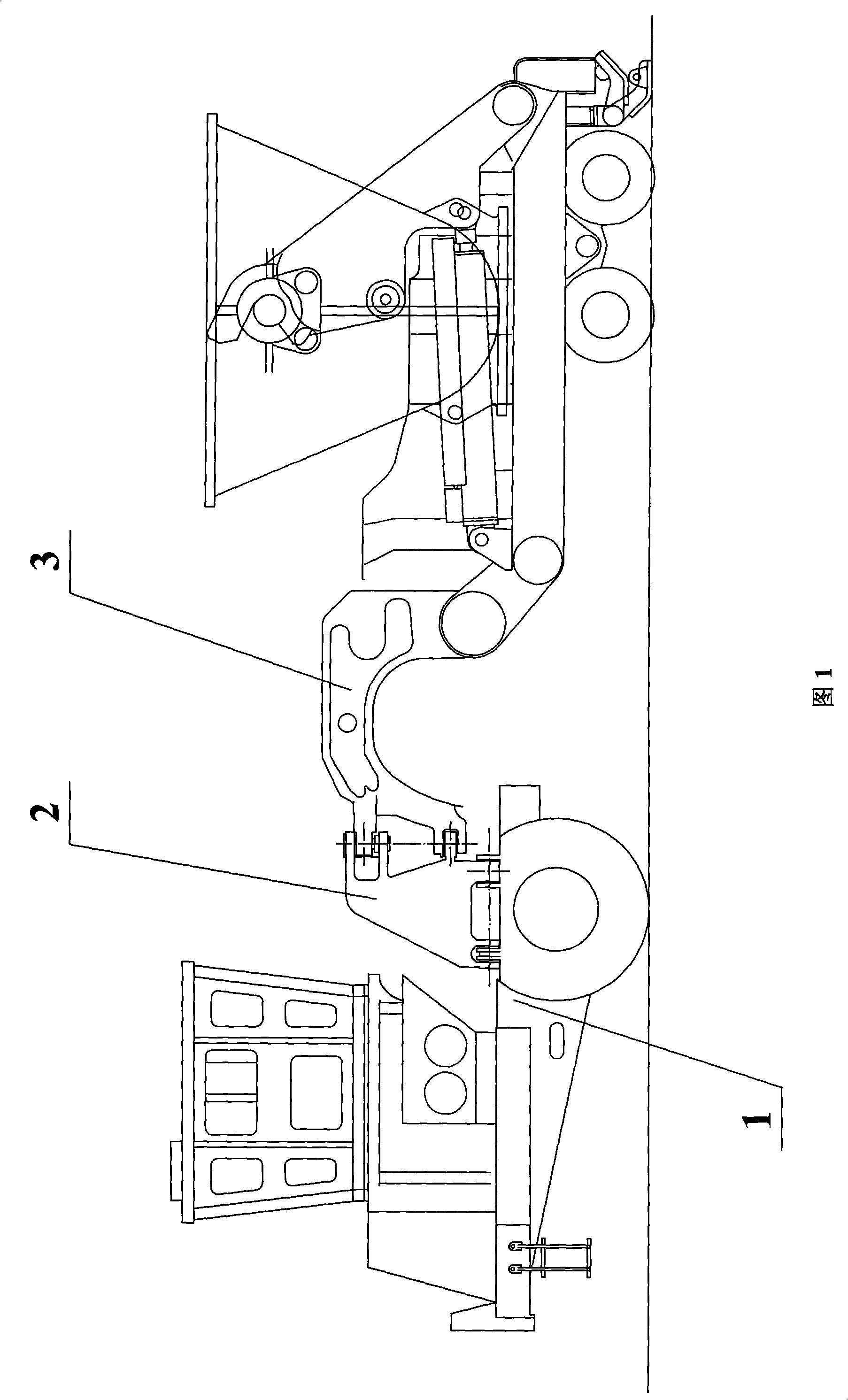

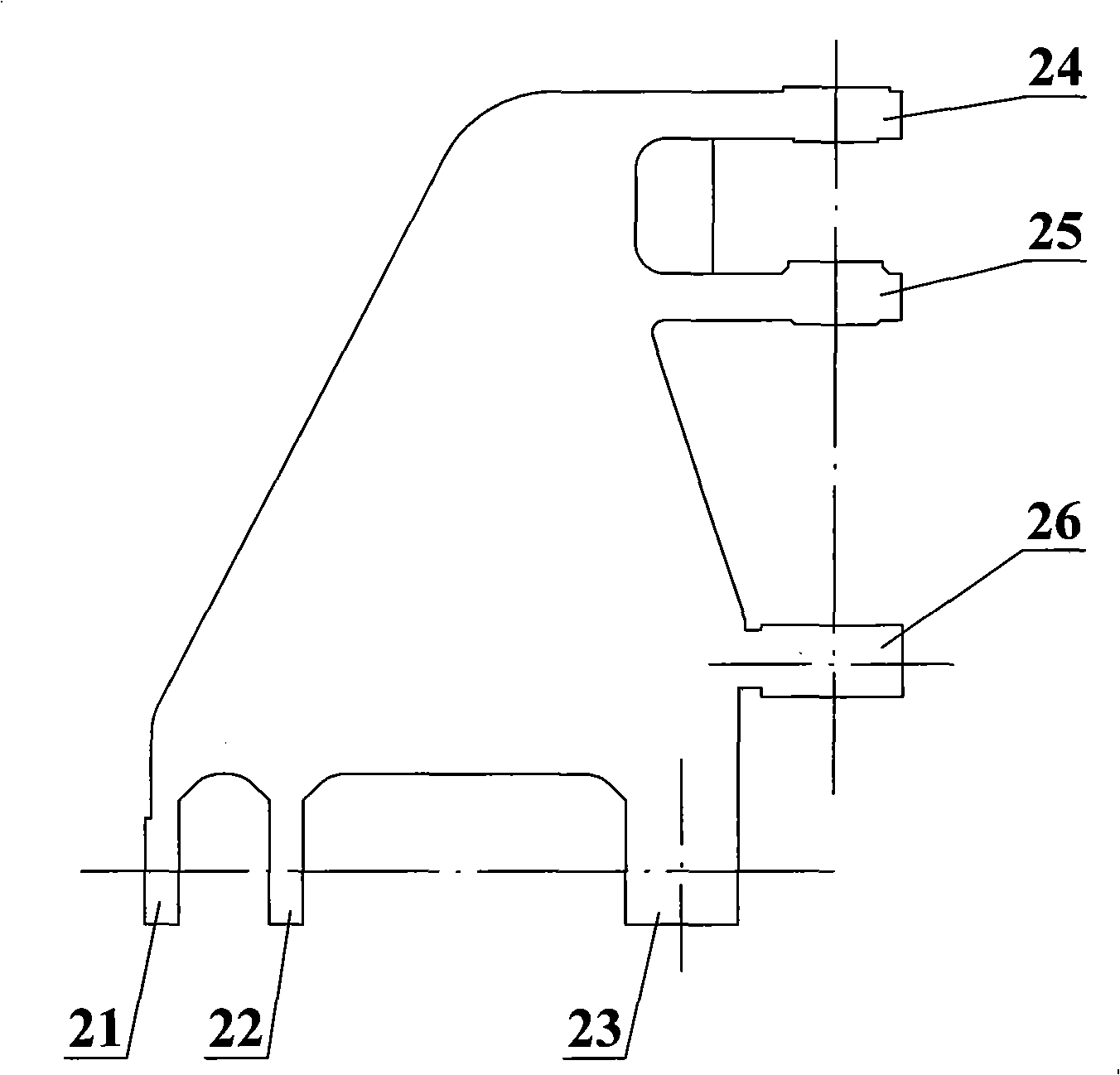

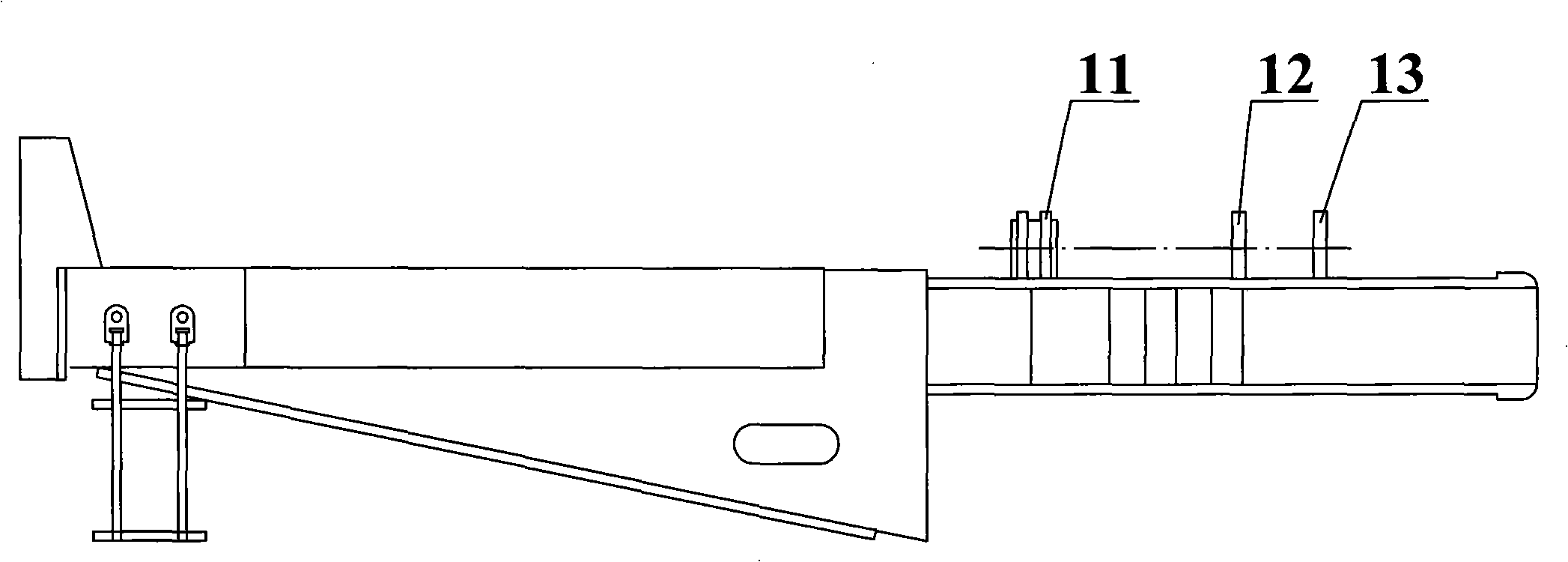

[0015] As shown in Figure 1, the frame structure of the articulated tank car is adopted, including the front frame 1, the intermediate coupling body 2 and the rear frame 3. The front vehicle frame 1 is provided with a load bearing and a drive axle with a power drive system. The front vehicle frame 1 and the power drive system are collectively referred to as the front vehicle body, which has the function of traction and walking. The rear vehicle frame 3 bottoms are also equipped with supporting vehicle axles, but without power drive, they are driven axles, which are called towed parts. The front and rear vehicle frames 1 and 3 are hingedly connected through the intermediate coupling body 2 . One end of the intermediate coupling body 2 is connected to the front frame 1 through an axial hinge, and the rotation axis of the axial hinge is parallel to the axis of the vehicle body; the other end of the intermediate coupling body 2 is connected to the rear frame 3 through a longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com