Process for preparing hydrocracking catalyst of high activity

A hydrocracking and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of poor catalyst reaction activity, no significant improvement in medium oil selectivity, and low catalyst activity. Significant improvement and other problems, to achieve the effect of reducing BMCI value, improving performance, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

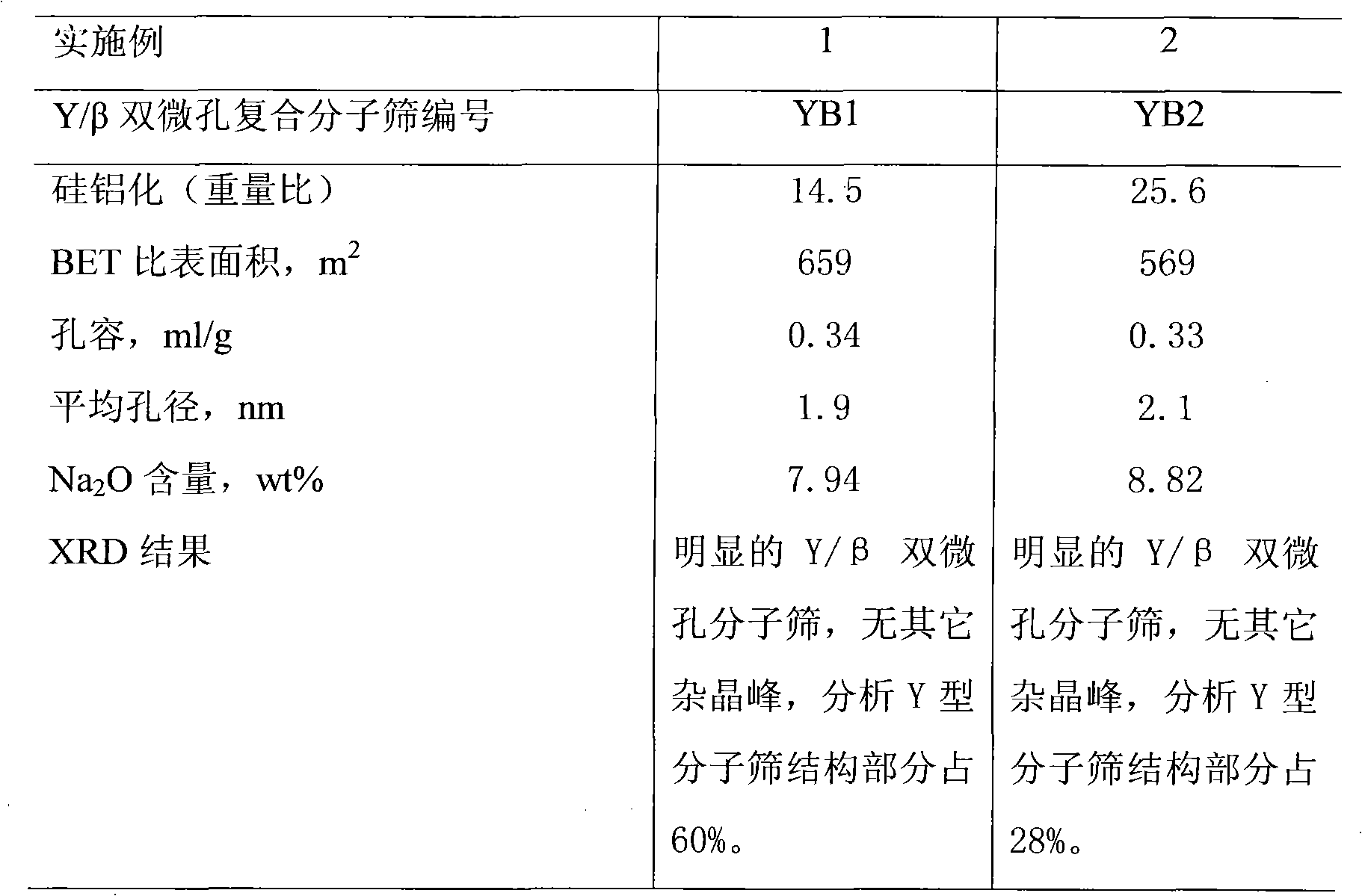

[0039] The Y / β double microporous composite molecular sieve is synthesized by the synthesis method of the double microporous composite molecular sieve disclosed in Chinese patent CN1583562A, and the specific steps are carried out according to Embodiment 2 in the patent. The obtained Y / β double microporous composite molecular sieve is coded as YB1.

Embodiment 2

[0041] The Y / β double microporous composite molecular sieve is synthesized by the synthesis method of the double microporous composite molecular sieve disclosed in Chinese patent CN1583563A, and the specific steps are carried out according to Embodiment 4 in the patent. The obtained Y / β double microporous composite molecular sieve is coded as YB2.

[0042] The main physicochemical properties of the Y / β double microporous composite molecular sieve obtained in Examples 1-2 are shown in Table 1.

[0043] Table 1 Main physicochemical properties of Y / β double microporous composite molecular sieves

[0044]

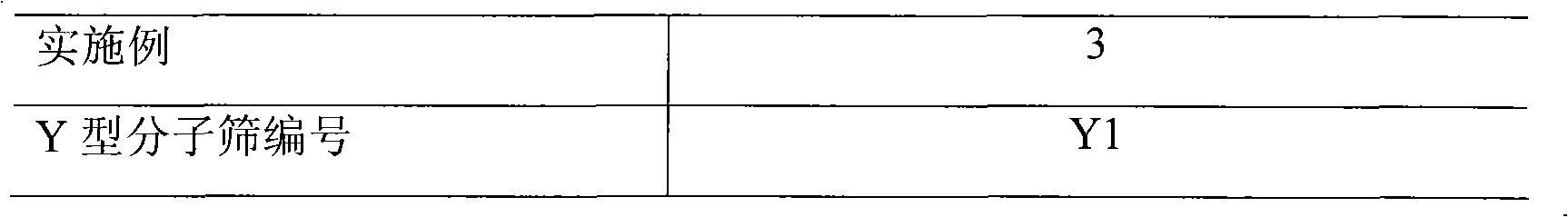

Embodiment 3

[0046] Y-type molecular sieve is produced by Wenzhou Huahua Group Co., Ltd. NaY, and the number is Y1. Its basic physical and chemical properties are listed in Table 2.

[0047] Table 2 The physicochemical properties of the Y type molecular sieve used in the present invention

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com