Doweling type wooden floor and method of processing the same

A tenon-joint wood and processing method technology, which is applied to wood processing appliances, manufacturing tools, floors, etc., can solve the problems of affecting the appearance and use, complex processing procedures, slow paving process, etc., and achieve easy connection and simple processing procedures. , the effect of good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

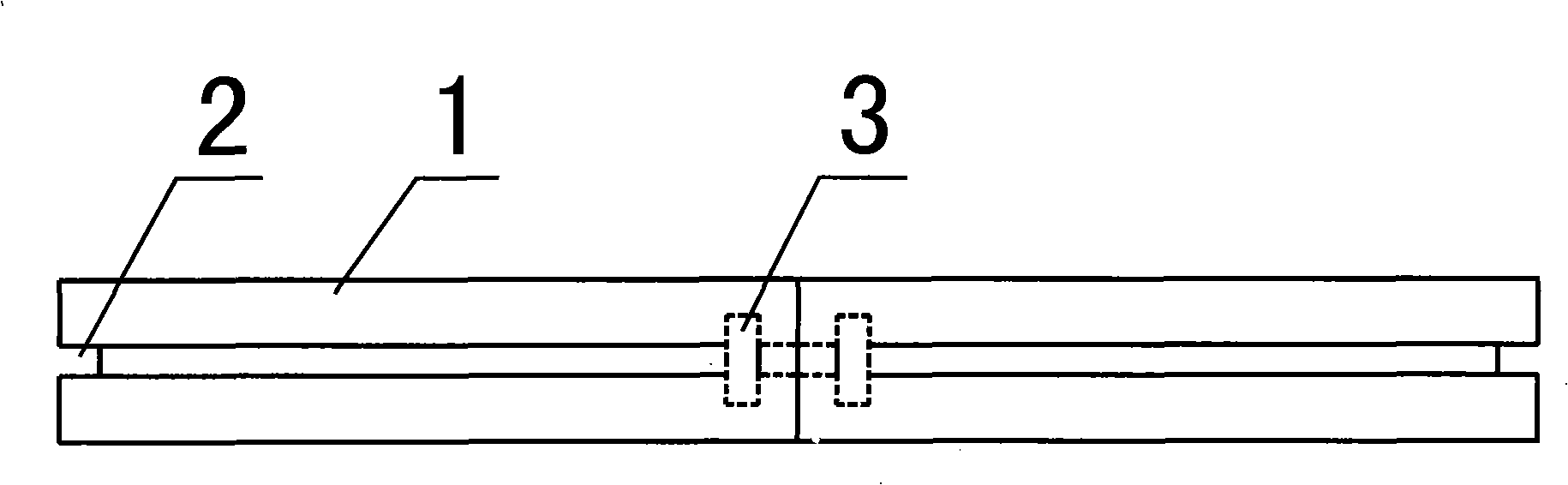

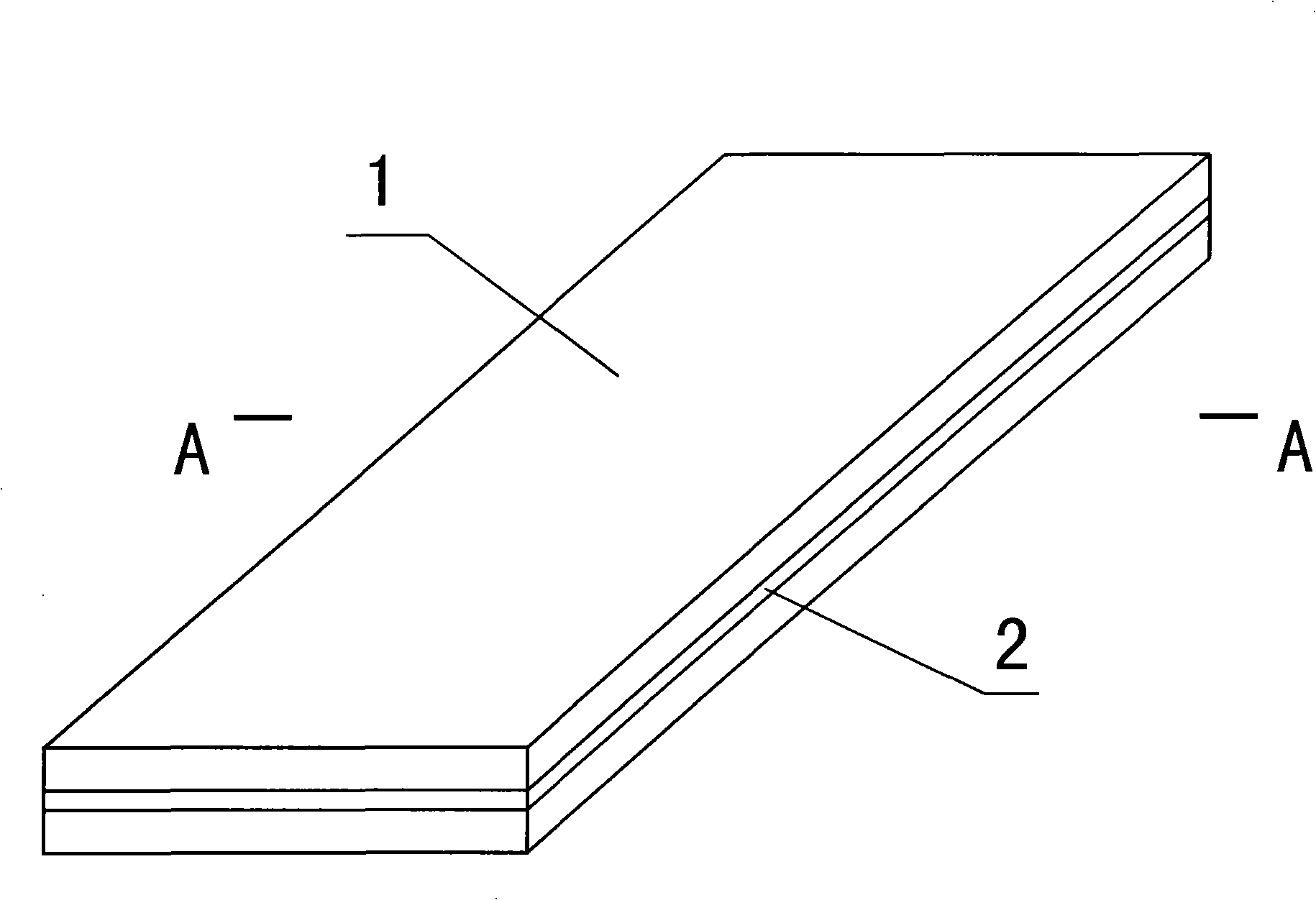

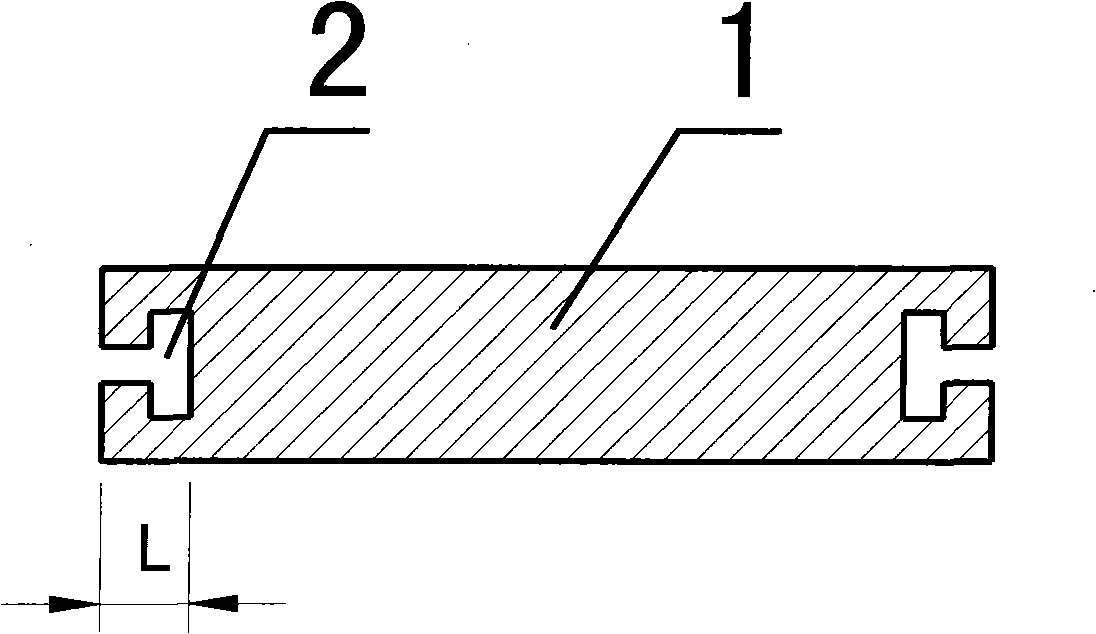

[0020] Example. Such as figure 2 As shown, T-shaped grooves 2 are formed on the four sides of each floor 1, and the floor 1 is spliced together with an I-shaped tenon 3 (such as figure 1 shown). The I-shaped tenon 3 is used for the connection between the boards when the floor is laid, and takes the role of the tenon joint. Its structure is as follows: Figure 4 shown. The I-shaped tenon 3 can be a wooden tenon or a metal tenon made of metal. The I-shaped tenon part 3 in this example is a homogeneous wooden tenon processed by using the homogeneous waste left over from cutting the floor embryonic board, which can reduce waste of raw materials and save costs. When laying, in order to make the boards tightly connected together, the depth L of the T-shaped groove 2 is required to be just 1 / 2 of the height H of the I-shaped tenon 3, or slightly smaller.

[0021] During processing, after the floor embryonic board is processed into a rectangular cuboid, special equipment is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com