Light concentration type full glass solar heat collection pipe

A solar collector tube and all-glass technology, applied in solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of low heat utilization rate, many heat transfer media, and inability to conduct heat, and achieve low cost , The process is simple, and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

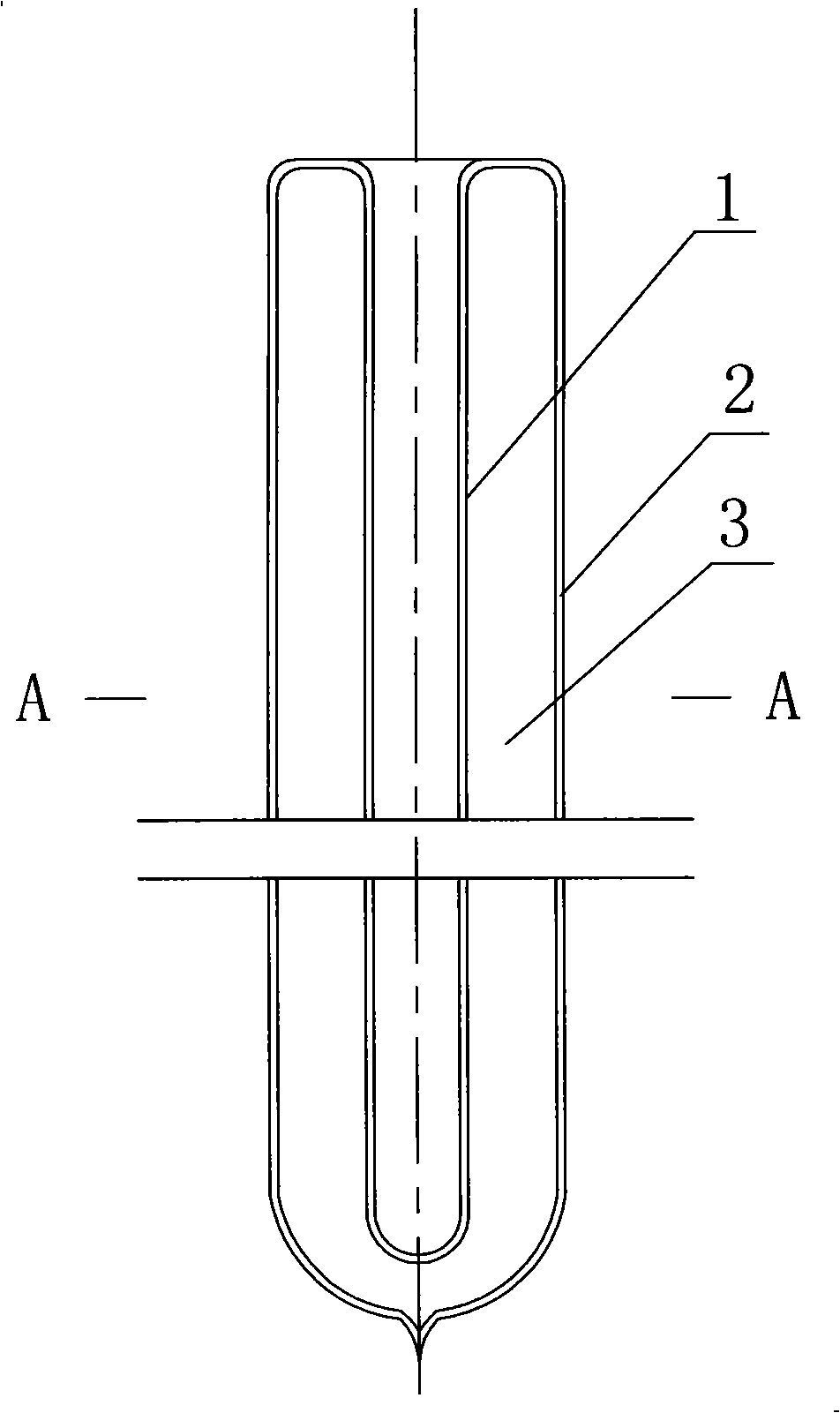

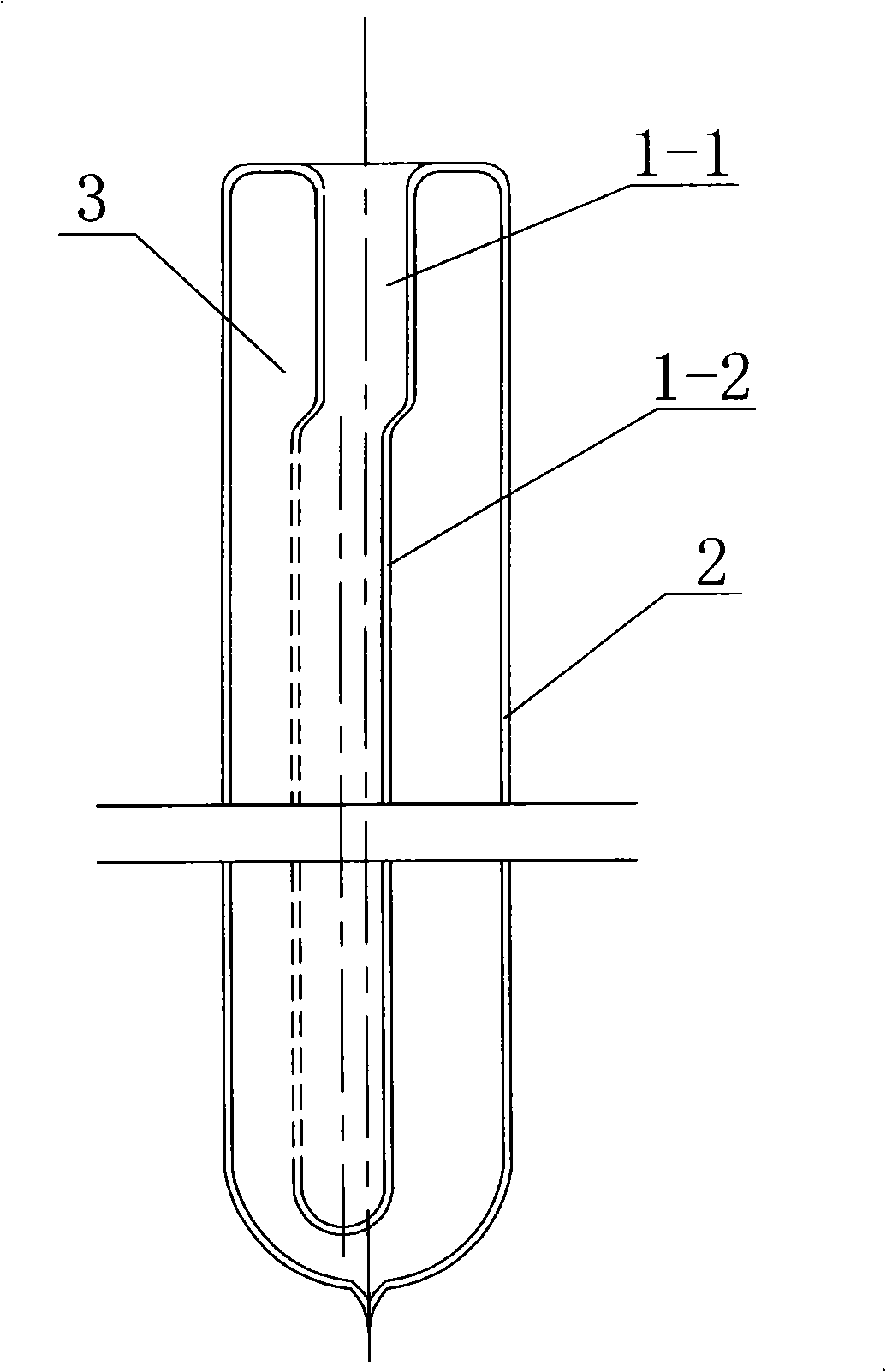

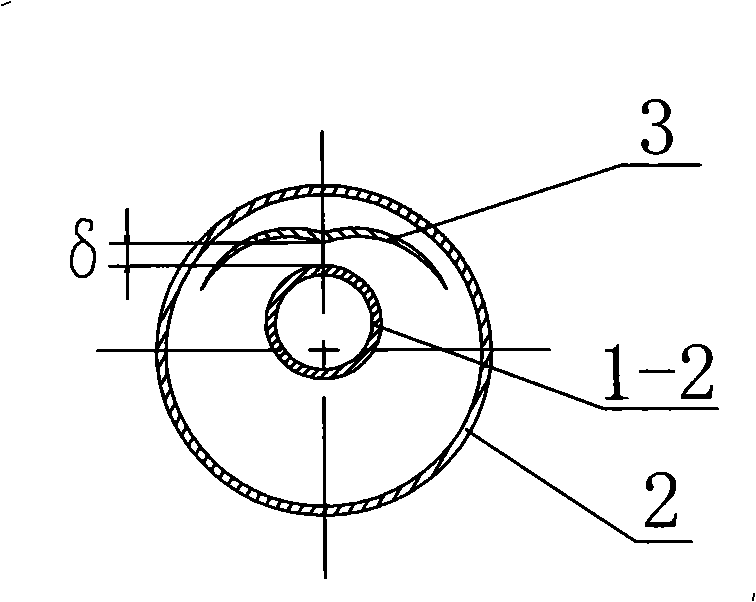

[0027] Such as figure 1 , 2 , 3, the present invention is mainly composed of an inner glass tube 1, an outer glass tube 2, and a reflector 3. The outer surface of the inner glass tube 1 is provided with a heat-absorbing film, and the inner glass tube 1 is divided into a welding section 1-1 and a conversion section 1 -2, the welding section 1-1 and the conversion section 1-2 are equal in diameter, the conversion section 1-2 is arranged eccentrically to the welding section 1-1, one end of the welding section 1-1 is connected to the conversion section 1-2, and the welding section 1-1 The other end of the outer glass tube is sealed with the outer glass tube 2, a vacuum is drawn between the inner and outer glass tubes 1 and 2, and the conversion section 1-2 of the inner glass tube 1 is arranged eccentrically to the outer glass tube 2.

[0028] The outer diameter of the inner glass tube is 1 / 6 to 1 / 2 of the inner diameter of the outer glass tube, which is 1 / 3 in the figure.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com