Polarization conversion unit, polarization conversion device, and projector

A technology of a conversion unit and a conversion device, applied in the field of projectors, can solve the problems of poor optics, increased manufacturing costs, and damage to optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

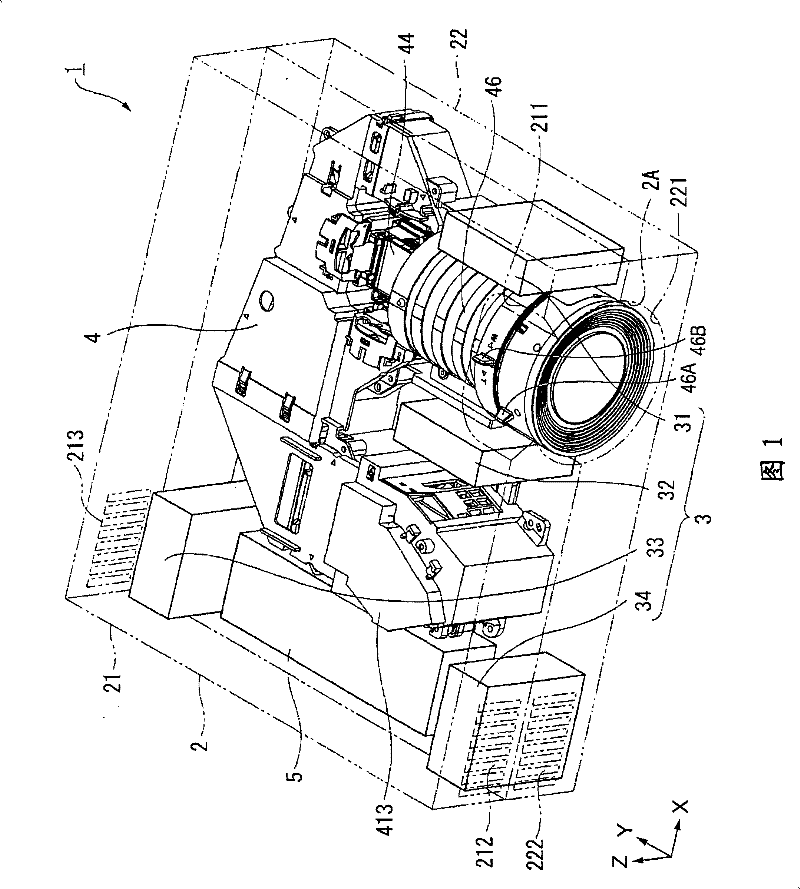

[0033] figure 1 It is a perspective view explaining the schematic structure of the projector in embodiment. refer to figure 1 , the configuration of the projector 1 will be described.

[0034] The projector 1 is composed of an exterior casing 2 having a substantially rectangular parallelepiped shape as a whole, and a cooling unit 3 for cooling heat accumulated in the projector 1 . Further, the projector 1 includes an optical unit 4 that optically processes light beams emitted from a light source to form an optical image based on image information, and a configuration that supplies power supplied from outside through a power cable (not shown) to the projector 1. The power supply unit 5 of the component is constituted.

[0035] The exterior casing 2 is formed of various metal materials, including: an upper casing 21 constituting the top, front, side, and back of the projector 1 respectively, and an upper casing 21 constituting the bottom, front, side, and The lower casing 22 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com