Production method of silicon based liquid crystal panel

A manufacturing method and silicon-based liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as CCD reading misjudgment, uneven slivers, and poor cutting accuracy, so as to improve the yield rate , reduce costs, and improve the accuracy of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] These drawings in the embodiments of the present invention are simplified schematic diagrams. However, these icons only show components related to the present invention, and the components shown are not the actual implementation. The number and shape of the components in the actual implementation are a selective design, and the layout of the components Possibly more complicated.

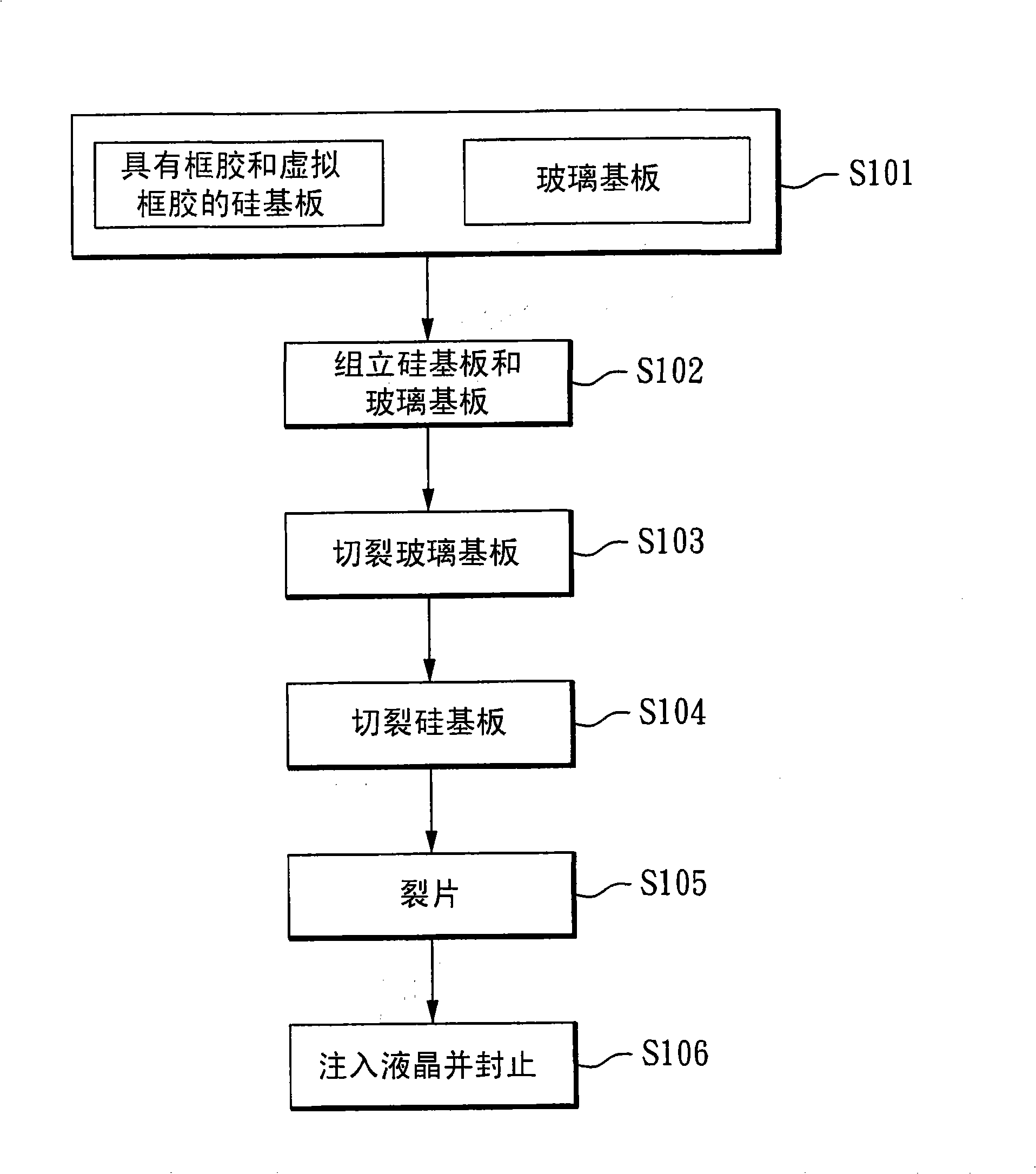

[0037] see Figure 4 , is a process flow of a method for manufacturing a liquid crystal on silicon panel according to a preferred embodiment of the present invention. Also refer to FIG. 5A to FIG. 5E , which are schematic cross-sectional views of the manufacturing method of the liquid crystal on silicon panel of the present embodiment.

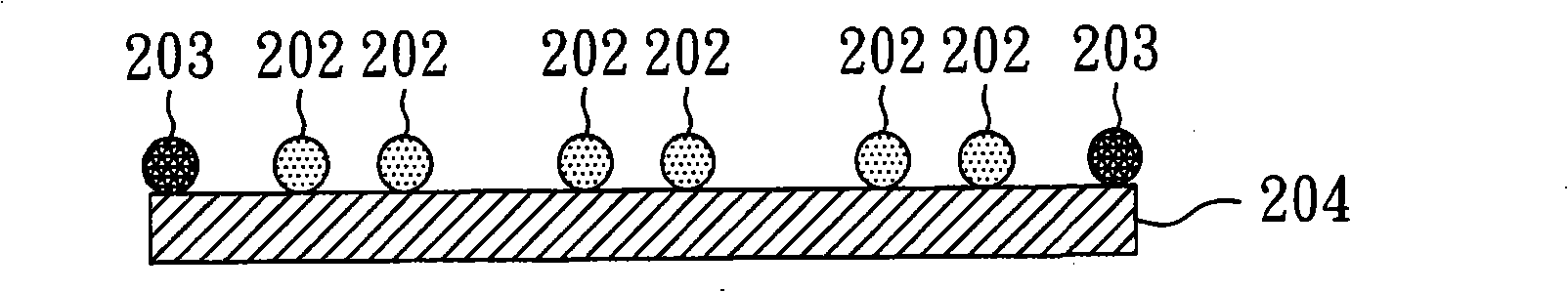

[0038] First, step S401 is performed, providing a silicon substrate 505 (see FIG. 5A ) that has completed the wafer integrated circuit method, and cutting the silicon substrate 505 to form a plurality of silicon chips 506 (see FIG. 5B ). In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com