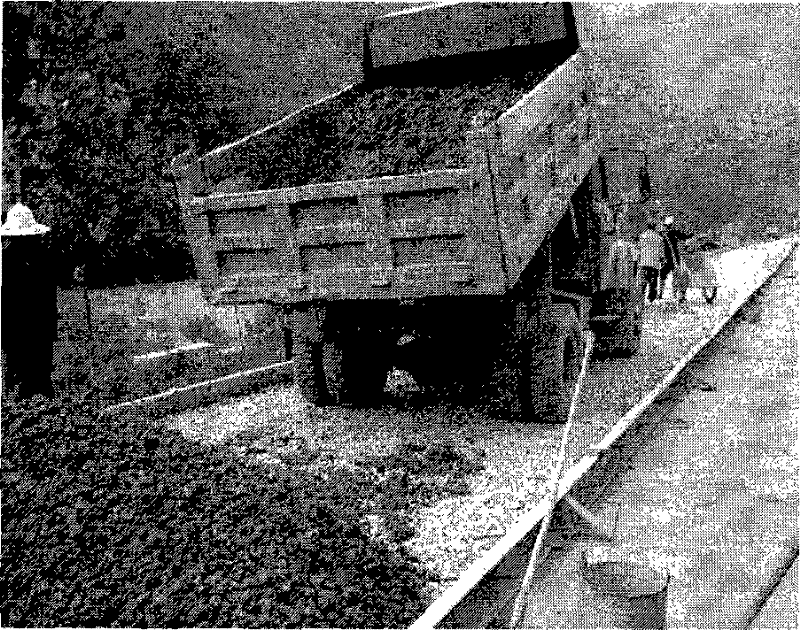

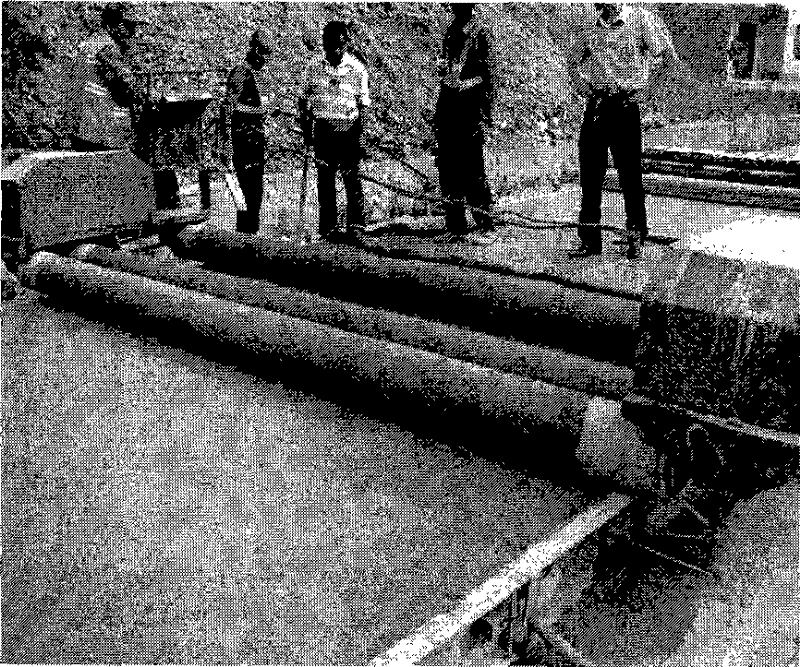

Construction process of throwing and filling aggregate pavement concrete

A technology of throwing and filling aggregate and construction technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve the problems of reduced construction efficiency, complex process, not suitable for large-scale mechanized construction, etc., to improve the construction efficiency. Efficiency, wear resistance improvement, effect of reducing the risk of shrinkage breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The proportion of the original pavement concrete is water: 32.5 grade fly ash cement: sand: gravel = 162:360:662:1230, the 7-day flexural strength of the concrete without throwing aggregates is 4.5MPa, and the compressive strength is 27.1MPa; 28 The daily bending resistance is 5.2MPa, 34.6MPa; the amount of gravel (aggregate) with a particle size of 20-60mm is mainly 5% of the volume fraction in the finished concrete, and the aggregate pavement concrete The 7-day flexural strength is 4.6MPa, and the compressive strength is 30.1MPa; the 28-day flexural strength is 5.3MPa, 38.2MPa. The average flexural strength converted from the splitting strength of the 6-core sample in 28 days of the physical project is 5.7MPa, which meets the strength requirement of the design value of 4.5MPa.

Embodiment 2

[0030] The proportion of the original pavement concrete is water: 32.5 grade fly ash cement: sand: crushed stone = 167:380:657:1225, the 7-day flexural strength of the concrete without throwing aggregates is 4.8MPa, and the compressive strength is 30.5MPa; 28 The daily bending resistance is 5.6MPa, 38.6MPa; the amount of gravel (aggregate) with a particle size of 20-60mm is mainly 10% of the volume fraction in the finished concrete, and the aggregate pavement concrete The 7-day flexural strength is 5.2MPa, and the compressive strength is 34.1MPa; the 28-day flexural strength is 6.2MPa, 41.2MPa. The average flexural strength converted from the splitting strength of the 5-core sample in 28 days of the physical project is 6.2MPa, which meets the strength requirement of the design value of 5.0MPa.

Embodiment 3

[0032] The proportion of the original pavement concrete is water: 42.5 grade ordinary silicon cement: fly ash: sand: gravel = 172:357:63:633:1175, the 7-day flexural strength of the concrete without throwing aggregates is 5.0MPa, and the compressive strength 30.5MPa; the 28-day flexural resistance is 6.0MPa, 40.1MPa; the above-mentioned particle size of throwing filling is mainly 20-60mm. The amount of gravel (aggregate) is 14% of its volume fraction in the finished concrete. The 7-day flexural strength of aggregate pavement concrete is 5.1MPa, and the compressive strength is 32.4MPa; the 28-day flexural strength is 6.1MPa, 42.6MPa. The average flexural strength converted from the splitting strength of the 5-core sample in 28 days of the physical project is 6.3MPa, which meets the strength requirement of the design value of 5.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com