Method for processing circular arc-shaped large space network frame supports and double supports thereof

A processing method and technology of large space, applied in the direction of building, building structure, etc., can solve the problems of unreliable stability of arc-shaped large space grid structure, hidden dangers in production and processing, etc., and achieve simple structure, convenient production, and increased stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

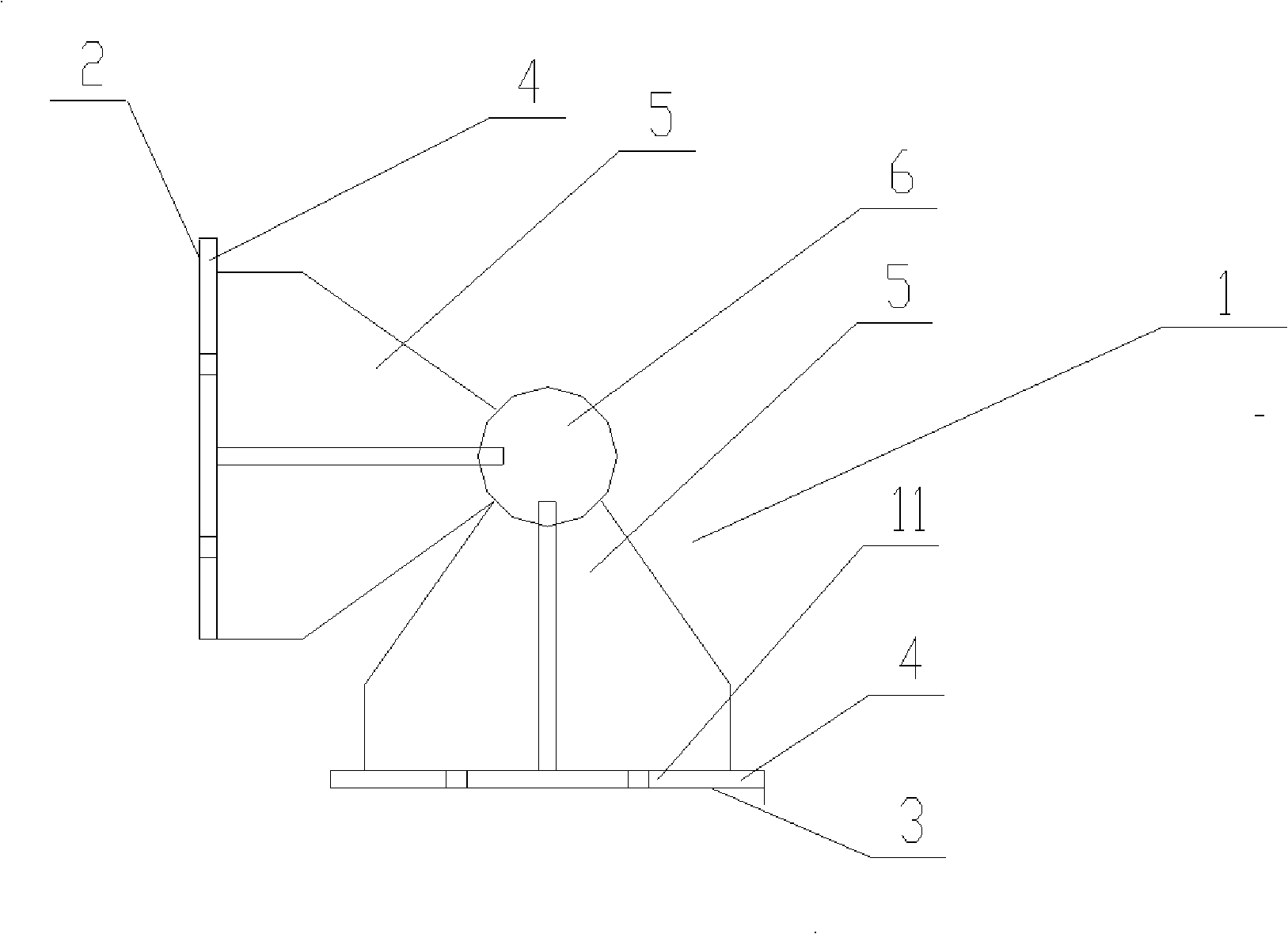

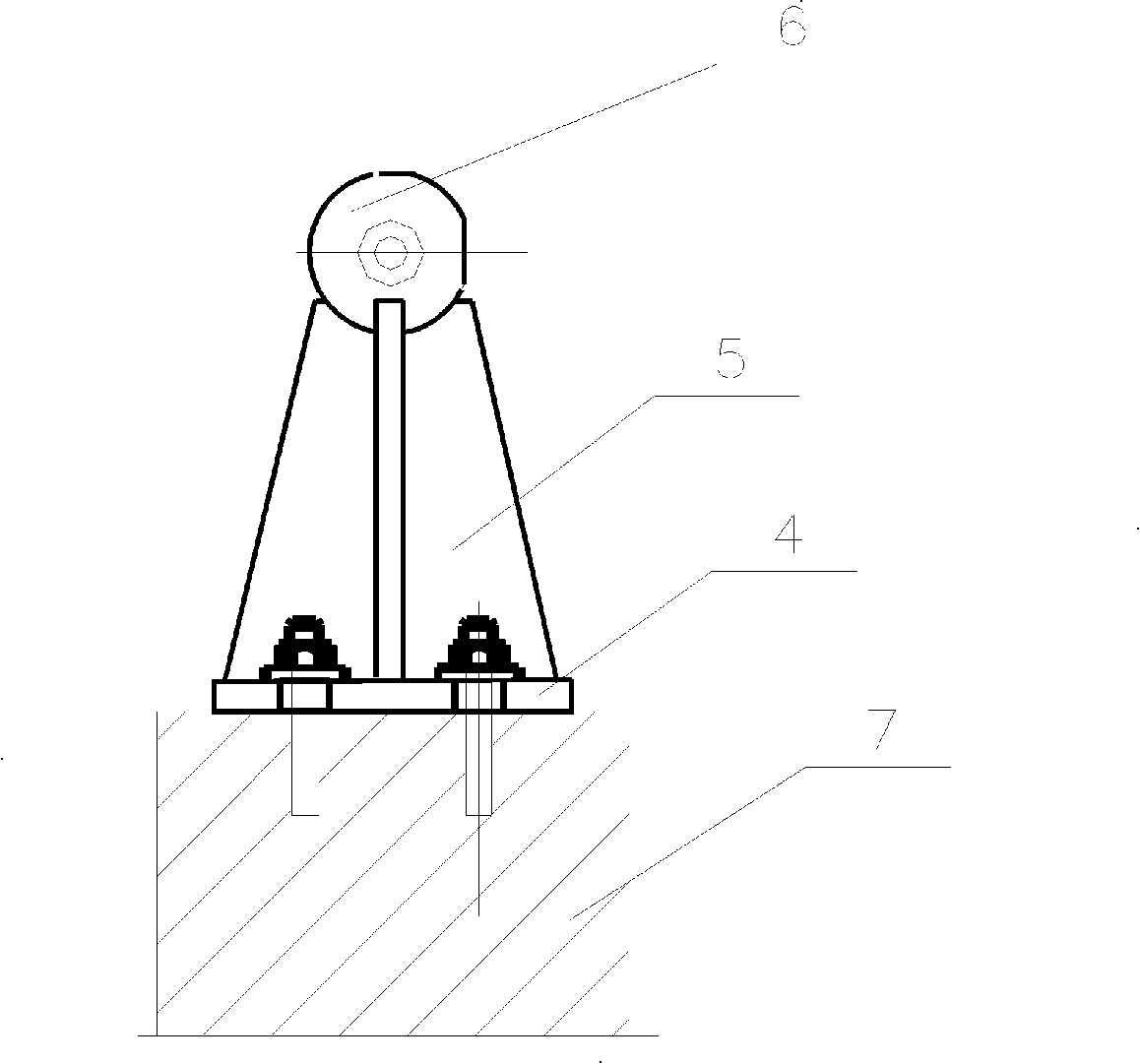

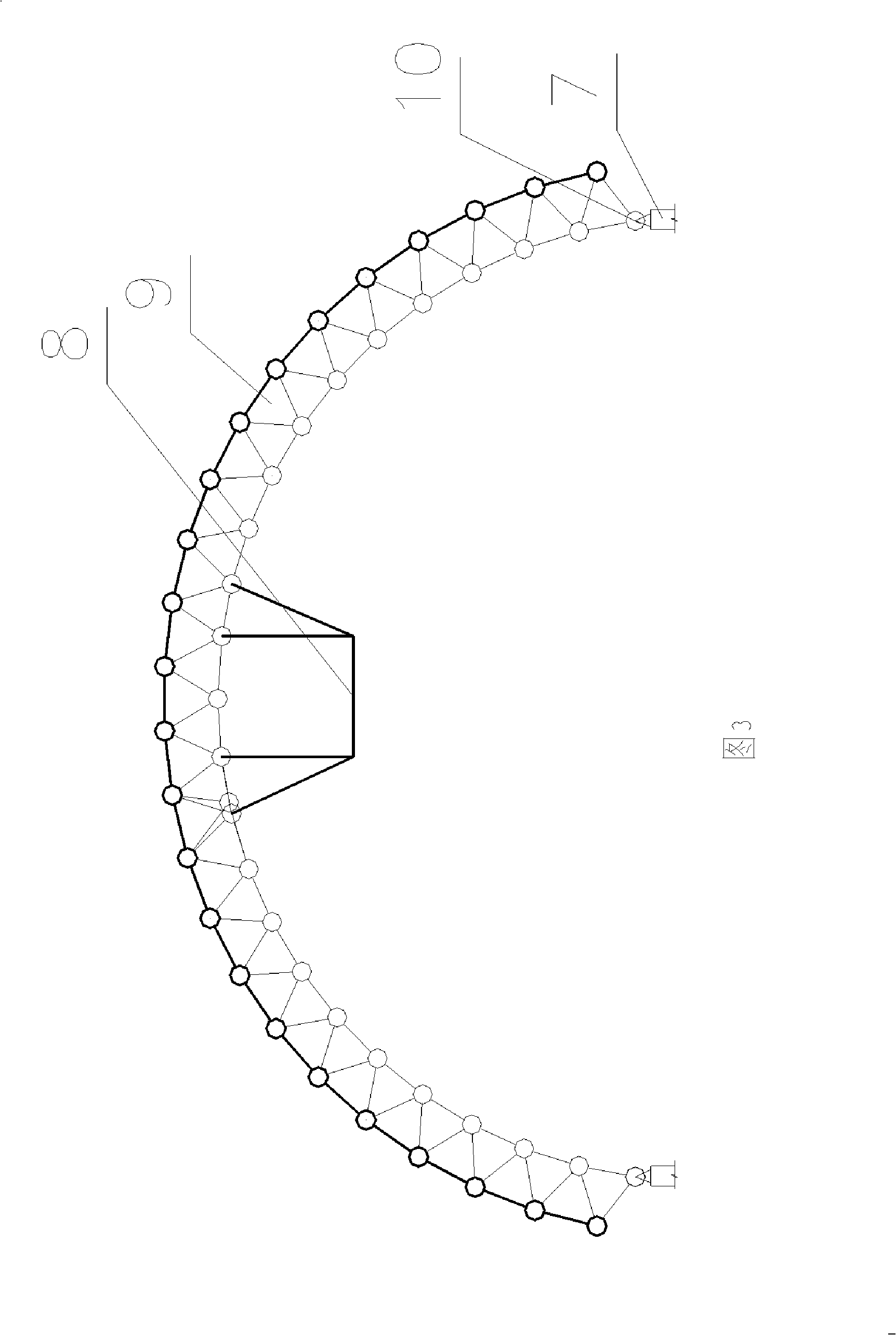

[0013] Embodiments of the present invention: the double supports of the arc-shaped large-space network frame of the present invention can be made according to the following method: the network frame support ball 6, stiff rib plate 5, and base plate 4 can be made by materials such as steel or iron; Drill 3 to 6 through holes on the two base plates 4 respectively, and weld the two base plates 4 on the two rib plates 5 respectively; weld the two rib plates 5 on the grid support ball 6, and make the The supporting surfaces 2 and 3 of the two base plates 4 are kept perpendicular to each other. Correspondingly, two supporting surfaces perpendicular to each other should also be made on the foundation short column 7 connected with the double support. During use, the two supporting surfaces 2 and 3 of the double support are respectively fixed on the two supporting surfaces of the foundation short column 7 by bolts, and then the arc-shaped large-space grid 9 is connected with the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com