Anti-vibration energy-saving building structure

A technology of building structure and double-layer structure, which is applied in the direction of building components, earthquake resistance, etc., and can solve the problems of many thermal bridges, easy condensation on the inner wall, mildew, and poor thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

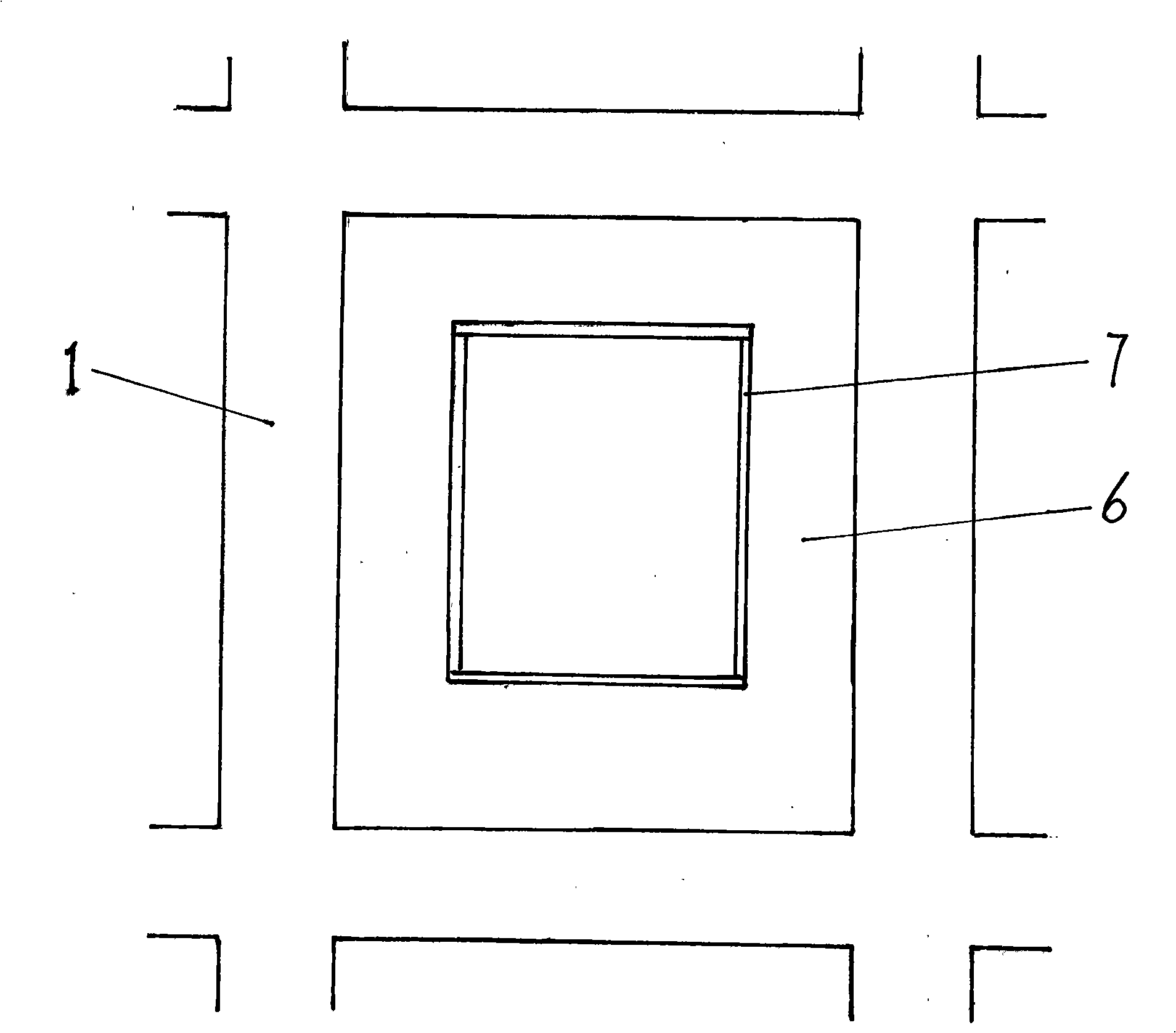

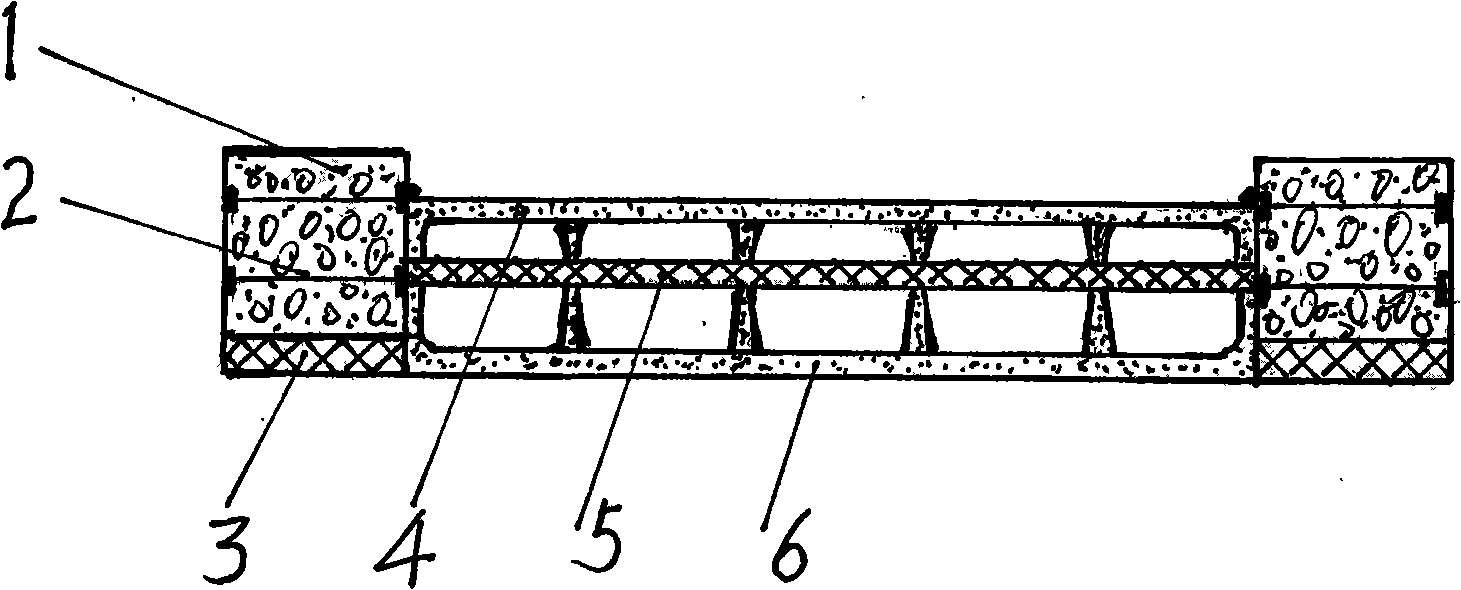

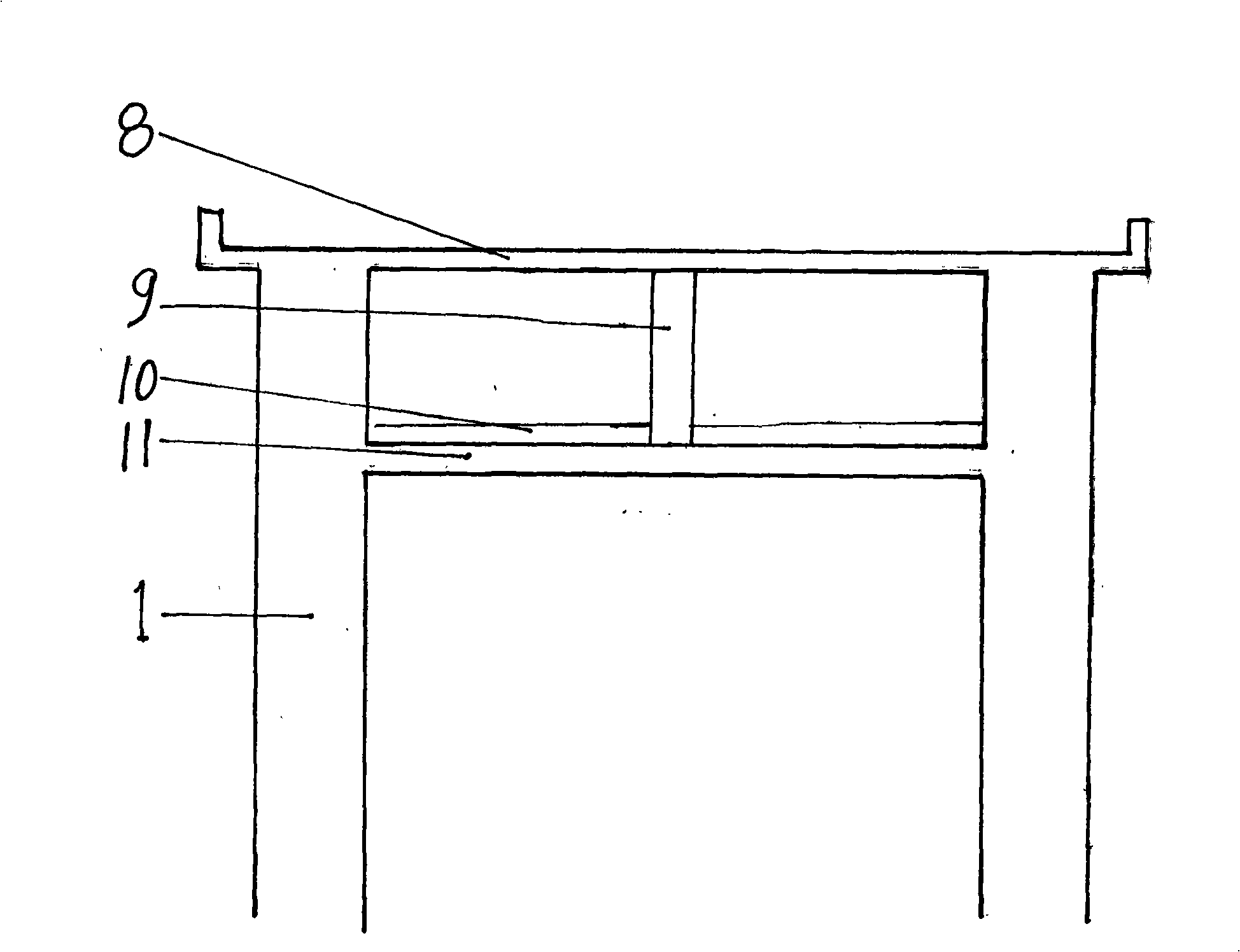

[0012] As shown in the figure, the strong foundation concrete frame 1 and the floor slab are the main body of the building structure. The H-shaped steel frame 2 is pre-buried near the four corners of the frame 1. The inner wall panel 4 and the outer page wall panel 6 are each a whole piece of lightweight concrete prefabricated panel. One side of the panel is flat and the other side is concave. There are attachments for fixed-page wall panels at each corner. Sandwich insulation board 5 can be to heat radiation reflective layer to make on both sides with foam plastic plate, also can be to make like this, promptly do lining with the plastic cloth that has heat radiation reflective layer, the waste plastic bag that reclaims, plastic box , plastic cups, plastic films, foam plastics, etc., after cleaning, they are made into air bags of different sizes. At the place, the glue is piled up to a thickness of about 5 cm, and a layer of fabric is glued on top, and the surrounding is fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com