Straight barrel type internal mold for building heat insulation heat preservation wall

A technology of heat insulation and heat insulation layer, which is applied in heat preservation, building structure, sound insulation, etc. It can solve the problems of fixed appearance, large space occupation, inconvenient transportation, easy breakage, etc., and achieves economical and convenient long-distance transportation. Reduce construction labor intensity, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

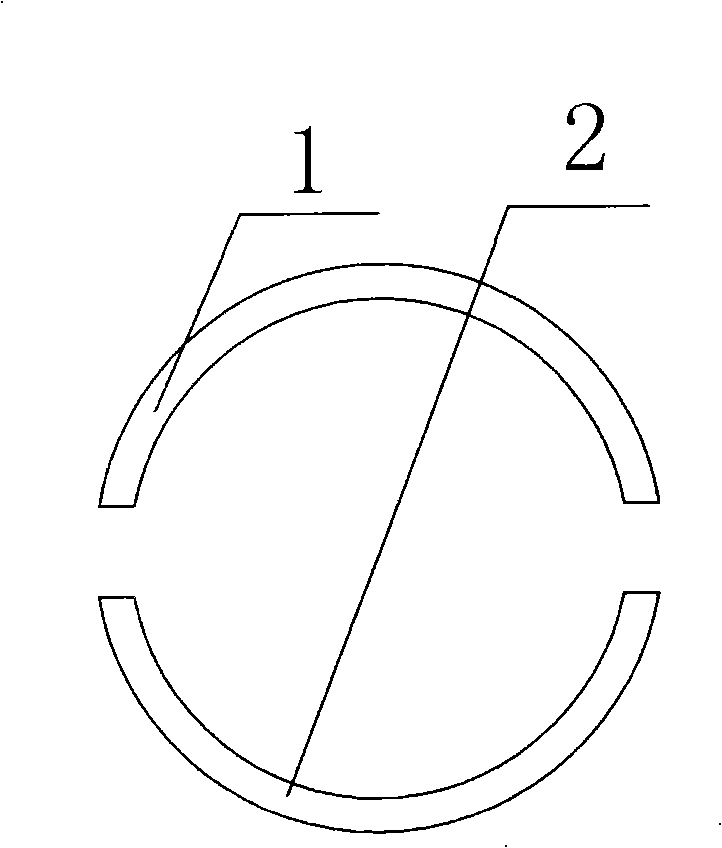

[0025] Embodiment 1, the present invention is composed of arc-shaped inner mold shell block 1 and outer mold shell block 2 symmetrically assembled to form a hollow inner mold with a cavity inside, and the inner mold shell block 1 and outer mold shell block 2 can be Made of polymer materials such as plastic or metal materials, it can be easily combined and assembled at the construction site. The cross-section of the hollow inner mold can be circular, square, polygonal, or any other regular and irregular shape . Iron wire can be used for fixing during installation and use. It is a heat-insulating wall formed by pre-embedding the hollow inner mold in the wall.

[0026] Its use method is: it can adopt a production mold suitable for the external dimensions of the wall body, or wall panel, or wall block, install and fix the production mold, and assemble the inner mold shell block 1 and the outer mold shell block 2 After the hollow inner mold is formed, a plurality of hollow inner m...

Embodiment 2

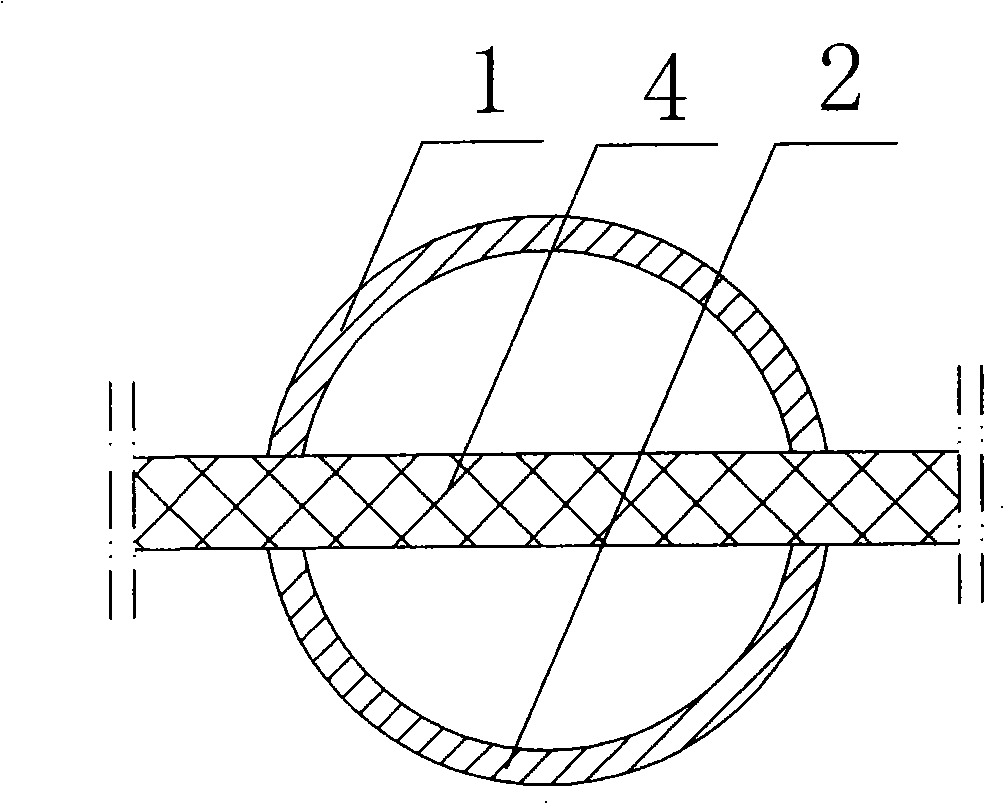

[0027] Embodiment 2, the present invention can form the inner mold by cooperating and installing the heat insulation layer 4 between the arc-shaped inner mold shell block 1 and the outer mold shell block 2, or install 2 on both sides of the heat insulation layer 4 Pairs or more than two pairs are combined and assembled by the inner mold shell block 1 and the outer mold shell block 2 to form a hollow inner mold, even if the open side of the inner mold shell block 1 and the outer mold shell block 2 is close to the heat insulation layer 4. The heat insulation layer 4 is a formed plate structure, which is applied to the construction of the outer wall, thereby further enhancing the performance of sound insulation, heat insulation and heat preservation, and can also save the existing building outer wall for heat insulation and environmental protection treatment And other processes, not only meet the country's energy-saving and environmental protection requirements, but also save proc...

Embodiment 3

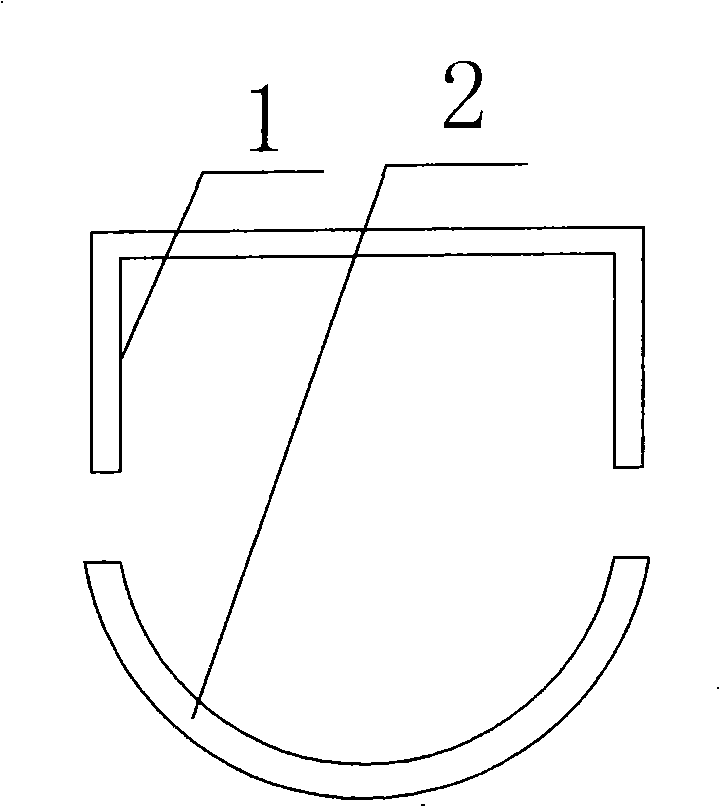

[0028] Embodiment 3, in the present invention, it is a hollow inner mold with a cavity inside formed by a symmetrical combination of a square groove-shaped inner mold shell block 1 and an arc-shaped outer mold shell block 2, and the inner mold shell block 1 A thermal insulation layer 4 is installed in conjunction with the outer mold shell block 2 to form an inner mold. refer to figure 2 and Figure 4 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com