Deep layer terrestrial heat renewable energy source winter heating method

A renewable energy, deep-seated technology, applied in the direction of renewable energy integration, geothermal power generation, heating methods, etc., can solve the problems of backward comprehensive energy-saving technology, high one-time cost, complex technology, etc., and achieve high practical value and promotion value , Renewable operating costs, endless effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

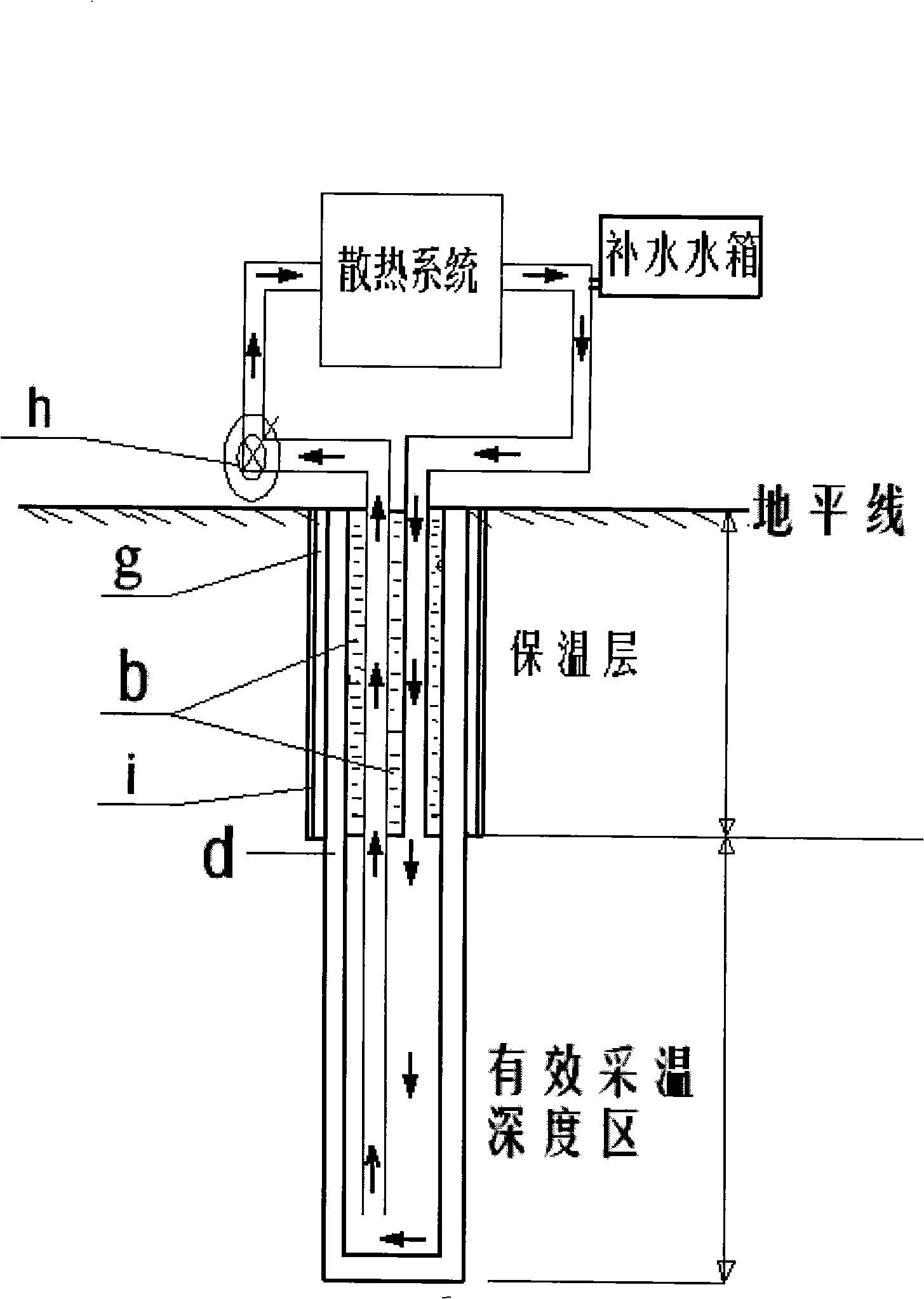

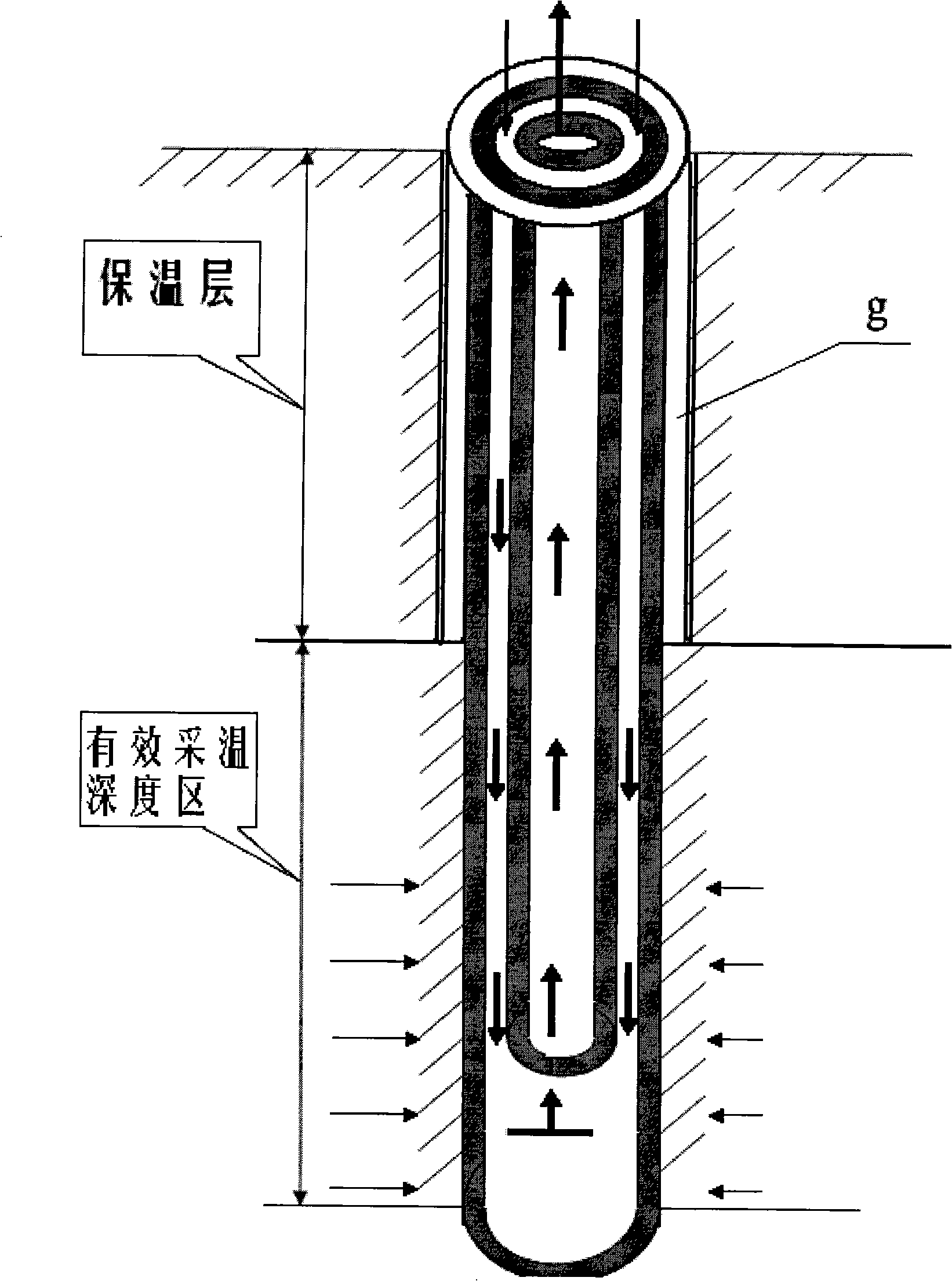

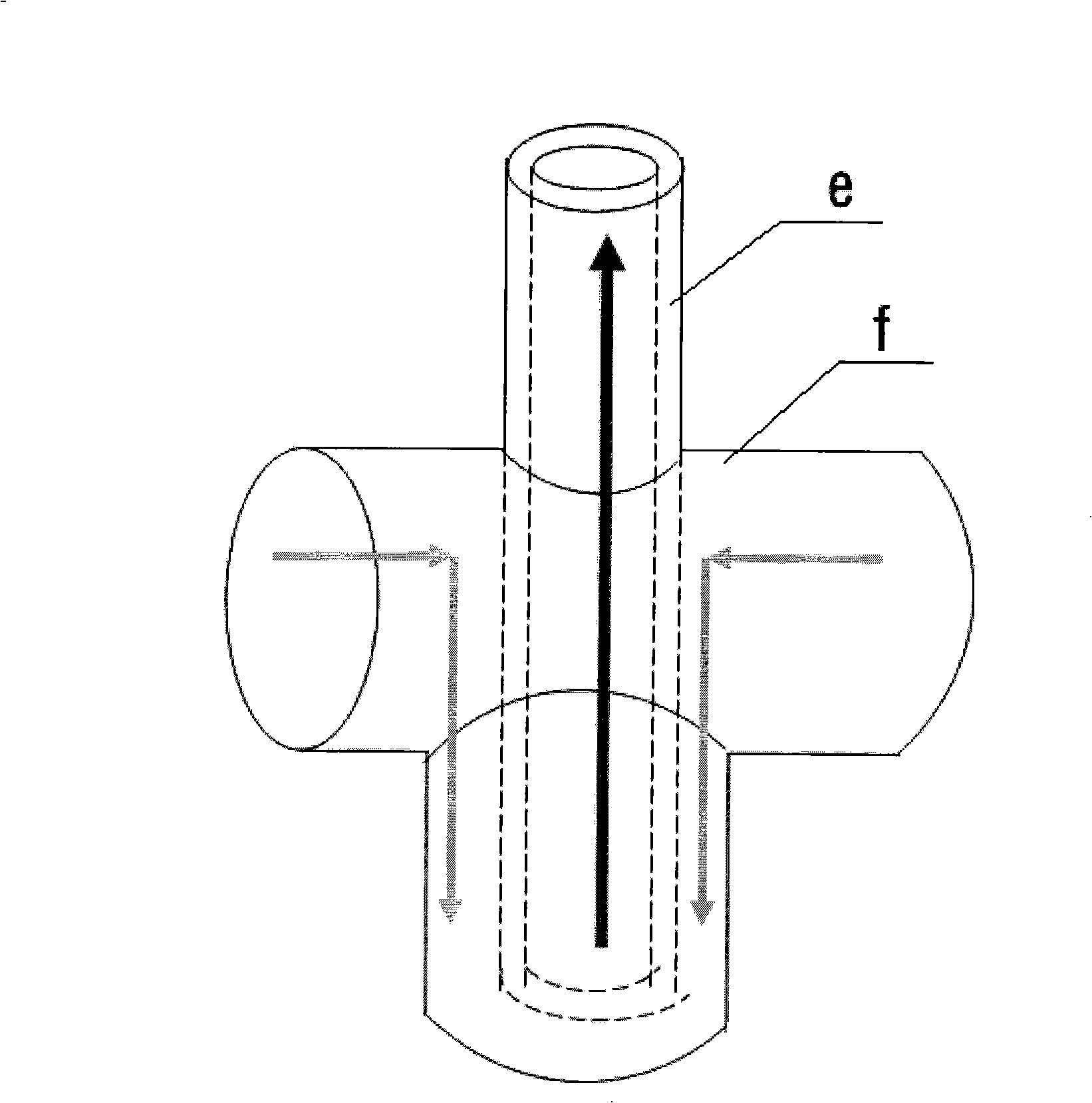

[0024] combined with Figure 2-4 , to further describe the present invention:

[0025] (1) Utilize a large drilling rig to drill a deep well with a diameter of 10 inches;

[0026] (2) stop drilling when the measured formation temperature reaches 40 degrees by logging equipment, and measure the well depth;

[0027] (3) Replace the 7-inch drill bit and continue drilling down;

[0028] (4) stop drilling when the measured formation temperature reaches 75-80 degrees, and measure the well depth;

[0029] (5) Calculate the length of the 7-inch well depth and the length of the 10-inch well depth;

[0030] (6) Lower the 7-inch casing to the bottom of the well, with a length of about 1000-1600 meters;

[0031] (7) At the same time, the 1-inch casing with thermal insulation protection layer reaches the junction of 10 inches and 7 inches, and the length is about 1,000 meters;

[0032] (8) Carry out cementing work at the bottom of the well; (9) Carry out cementing work at the upper we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com