Two-freedom degree electric machine actuating mechanism and corresponding six-freedom degree micromotion platform

A technology with motor execution and degrees of freedom, applied in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve problems such as small adjustment range, and achieve the effects of good integration, compact structure and good control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is based on Figure 1 to Figure 7 A preferred embodiment of the present invention is given and described in detail for the purpose of making it easier for those skilled in the art to understand the structural features of the present invention, rather than to limit the scope of the present invention.

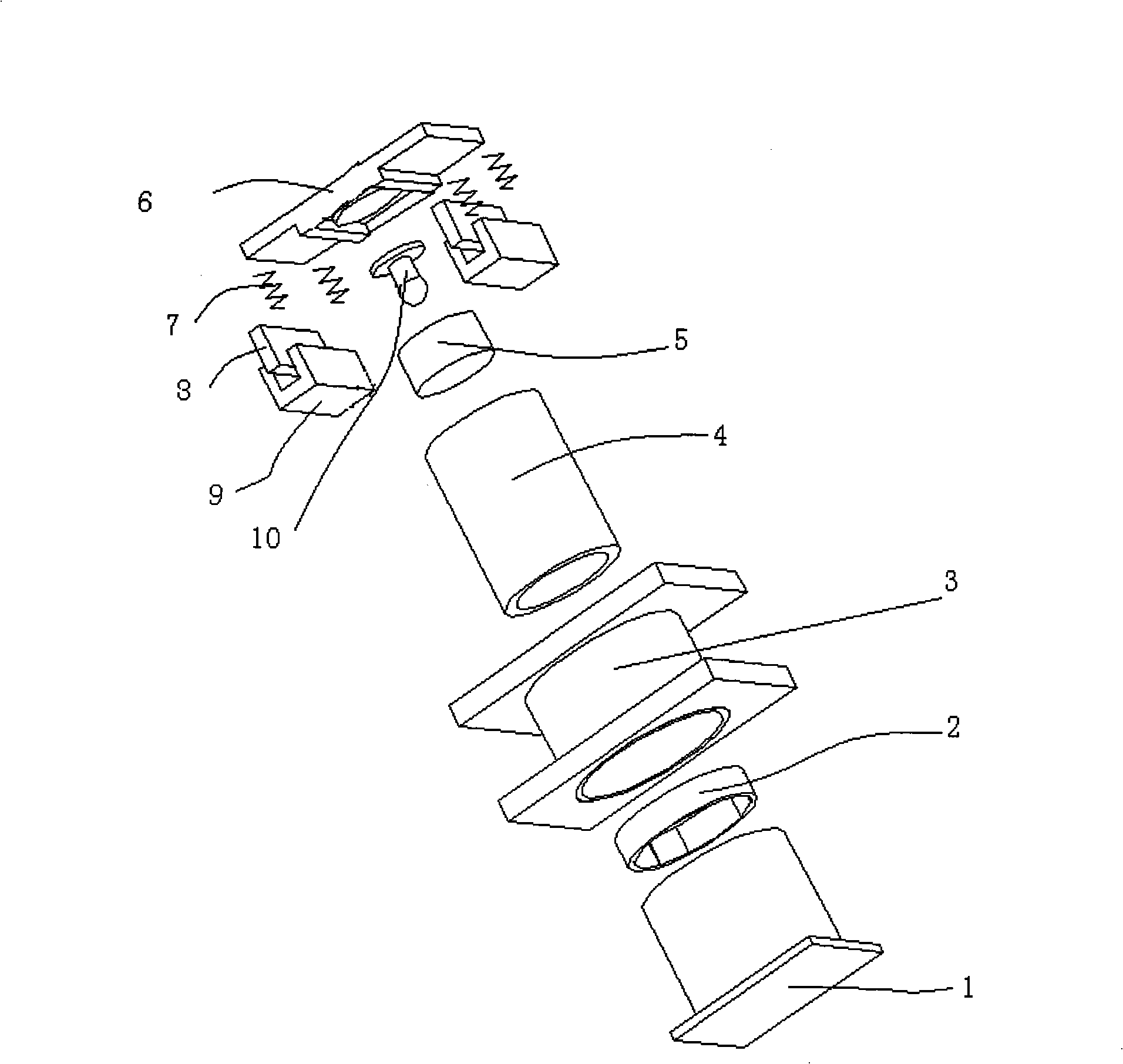

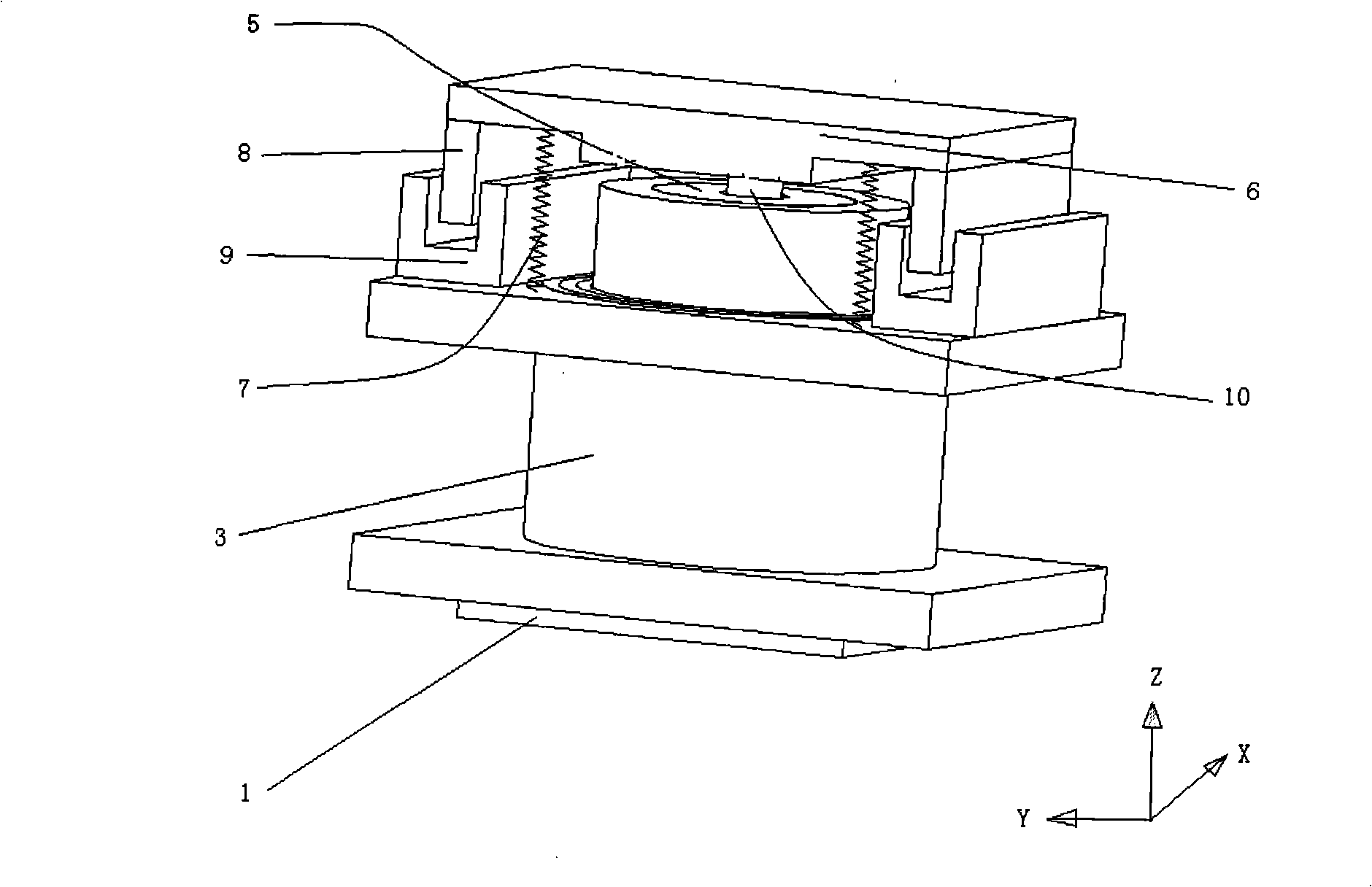

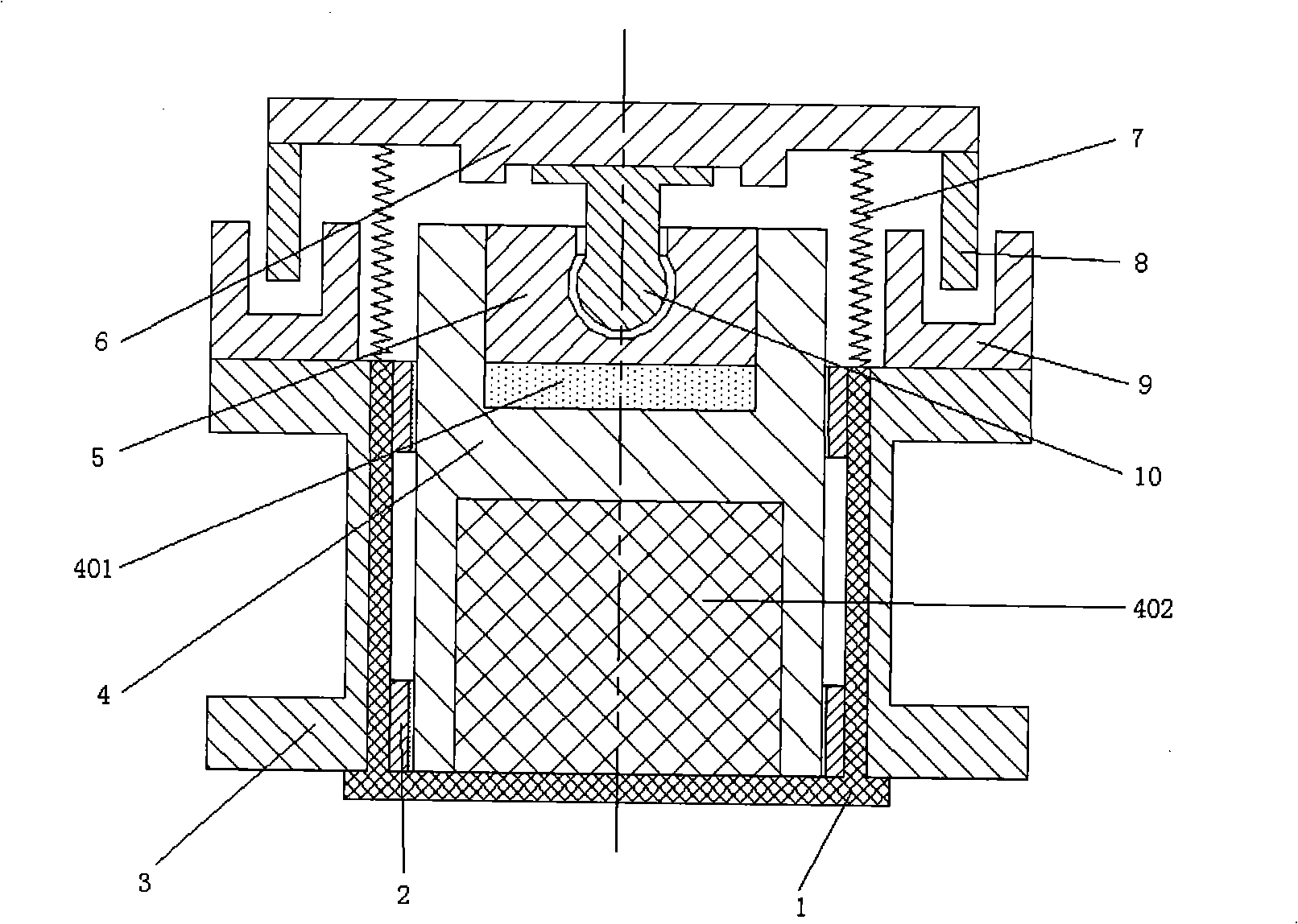

[0020] The invention provides a two-degree-of-freedom motor actuator and a corresponding six-degree-of-freedom micro-motion stage. Such as figure 2 The two-degree-of-freedom motor actuator is shown, and three such actuators are evenly distributed on the base at 120° (such as Figure 5 , Figure 6 , Figure 7 ), which can form a six-degree-of-freedom micro-motion table. The micro-motion stage realizes the six-degree-of-freedom adjustment with small stroke, that is, the horizontal movement in X, Y, and Z directions and the rotational movement in θx, θy, θz. The vertical adjustment stroke is ±1.5mm, the horizontal adjustment stroke is ±1.5mm, the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com