Electric meter production management system

A production management system and electricity meter technology, applied in the direction of electrical program control, instruments, collaborative operation devices, etc., can solve the inability to understand the problems and the corresponding causes, solutions, the inability to know the number of electricity meters in real time, and the number of completed online. Problems such as defective rate and inability to trace the production process information of electric meters to achieve the effect of solving complaints and improving satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

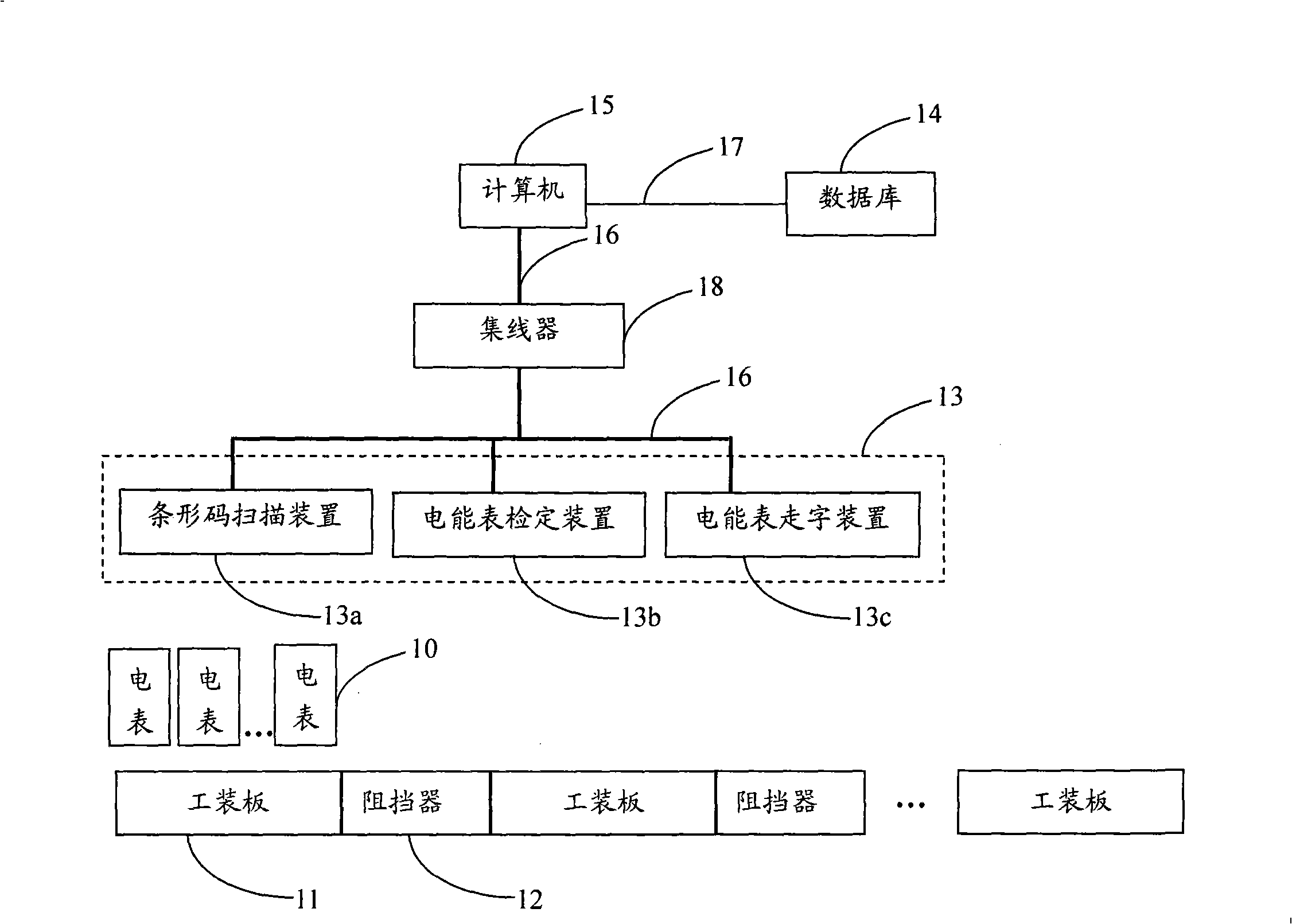

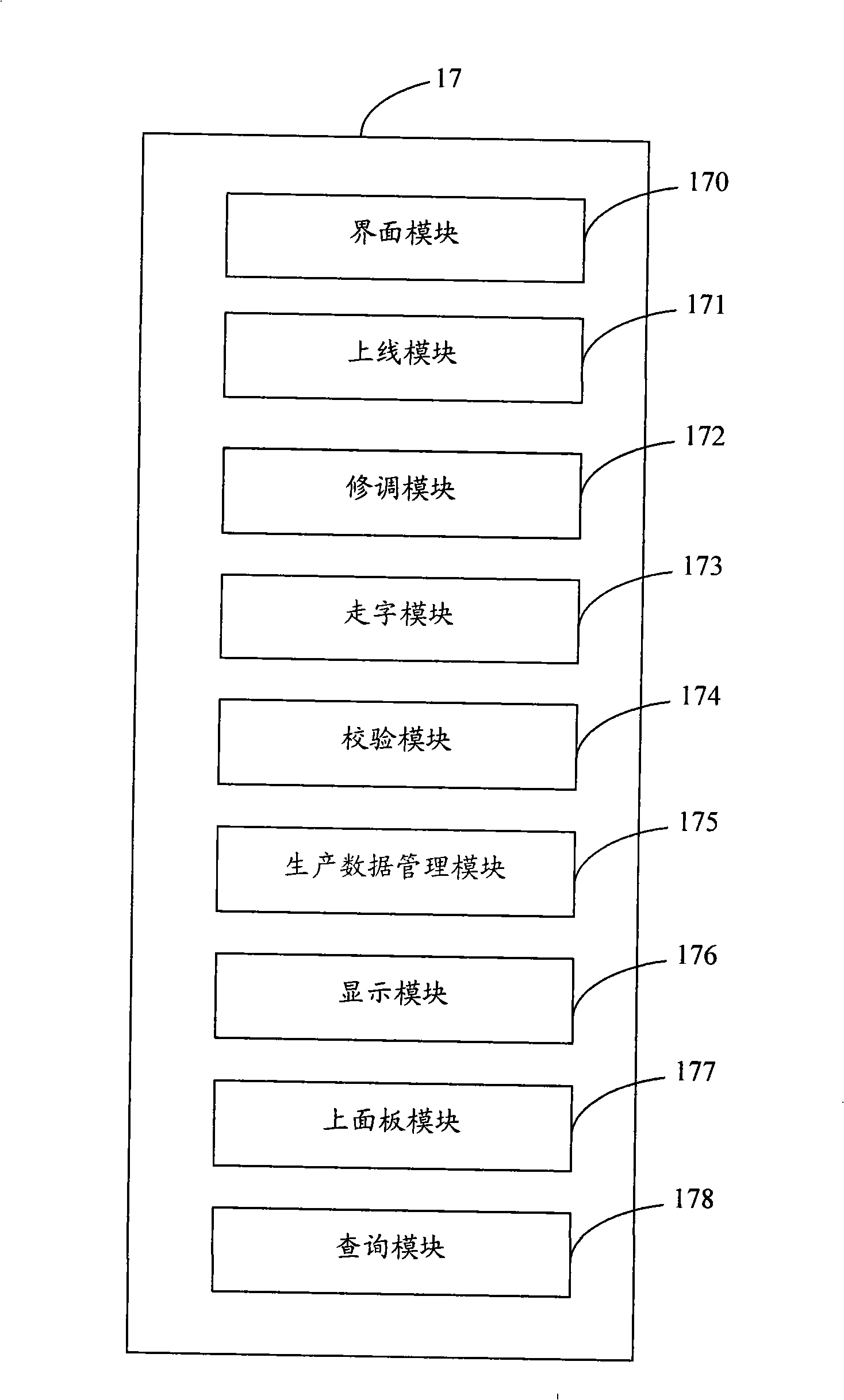

[0009] like figure 1 As shown, it is a hardware architecture diagram of the electric meter production management system in an embodiment. In this embodiment, the production process of the electric meter includes the following processes: on-line, adjustment, reading, calibration, panel-on and off-line. Among them, the on-line process is used to prepare the electric meter for the assembly line; the repairing process is used to repair and adjust the electric meter on the assembly line; the digital operation process is used to conduct a digital test on the electric meter on the assembly line; the verification process is used to verify the electric meter on the assembly line ; The upper panel process is used to install the electric meter casing on the electric meter on the assembly line; the offline process is used to prepare the electric meter for the downstream assembly line. Wherein, the order of the inspection process and the upper panel process can be exchanged in other imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com