Metal molybdenum and aluminum oxide composite ceramic insulation structure as well as preparation method thereof

A technology of alumina ceramics and composite ceramics, which is applied in the direction of ceramics, insulators, insulators, etc., and can solve problems such as poor reliability and unstable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a composite ceramic insulating structure with variable dielectric constant or resistivity, comprising the steps of:

[0021] 1) The columnar alumina ceramic substrate 1 is prepared by conventional electronic ceramic technology, and its two ends are ground flat; the columnar alumina ceramic substrate 1 is 75, 85 or 95Al 2 o 3 porcelain body.

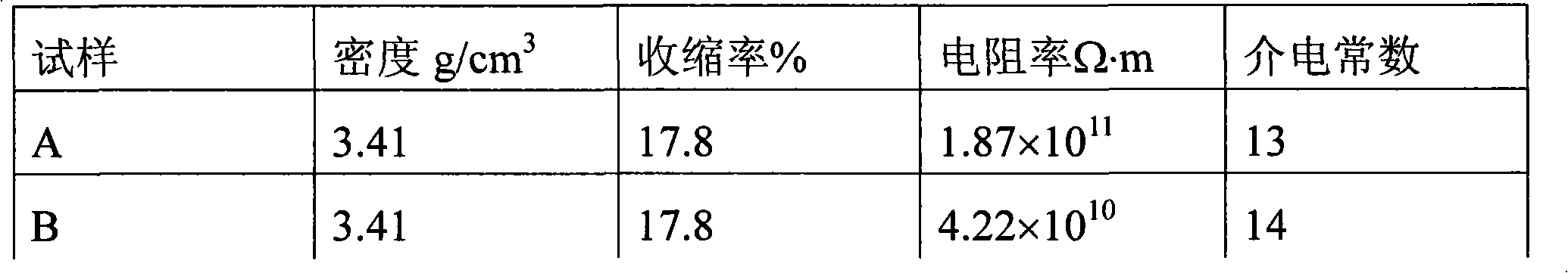

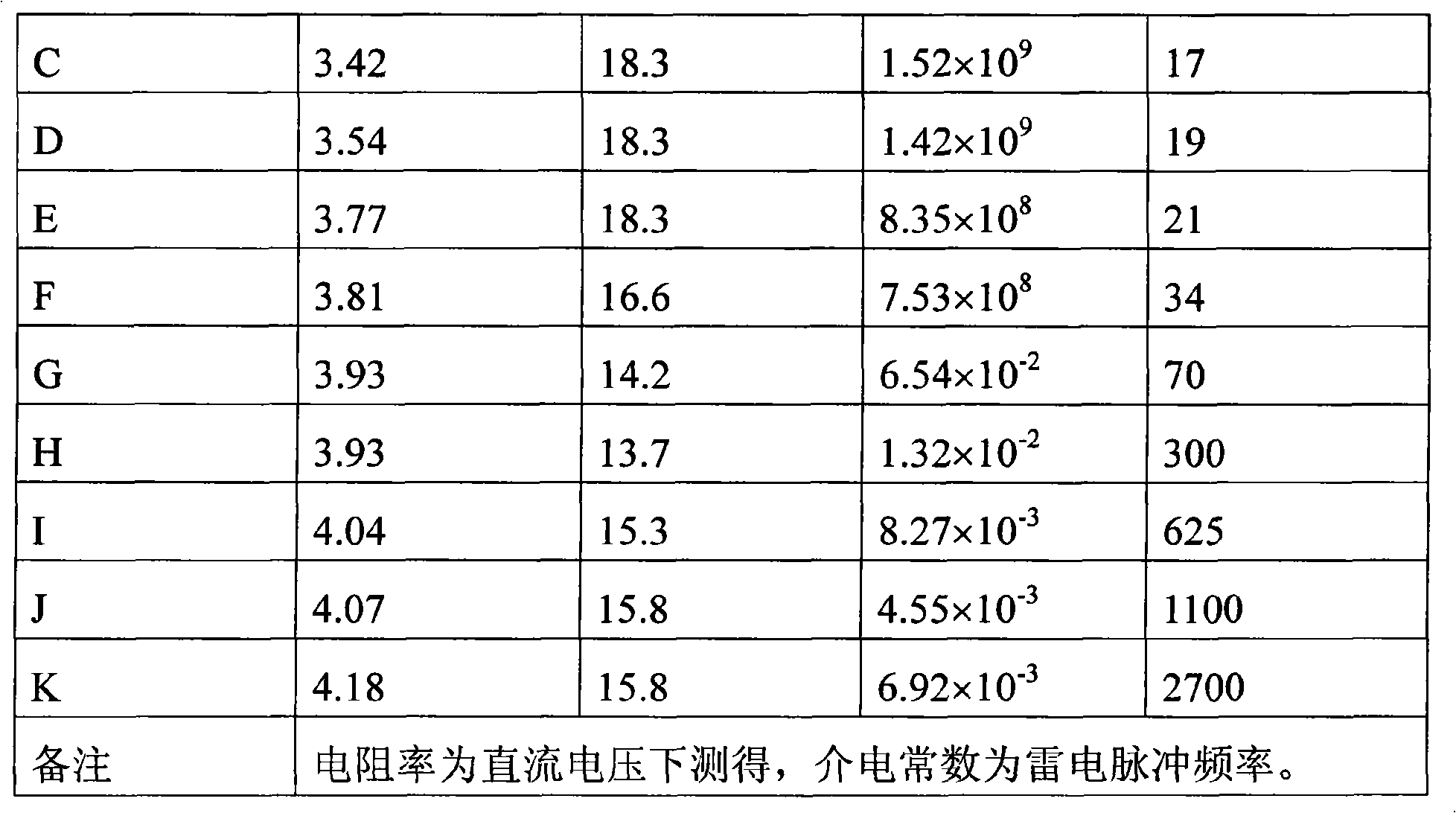

[0022] 2) Prepare molybdenum-doped alumina-based cermet disc 2, take 0.1-25% molybdenum powder and Al 2 o 3 Porcelain powder 75~99.9% is weighed (see Table 1 for specific composition), Al 2 o 3 Porcelain powder can be 75, 85 or 95Al 2 o 3 Porcelain powder, the powder is mixed with absolute ethanol, ball milled for 4-6 hours, dried at 100°C and then granulated, the binder is dextrin, material: dextrin = 100:1; A column press presses it into a φ24×2.6mm disc-shaped green body under a pressure of 4MPa. Heat the green body at 210°C for 20 hours to remove the glue, then sinter at 1500-1700°C for 1-4 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com