Spherical parts batch plasma based ion injection method and apparatus thereof

An ion implantation device and plasma technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of inability to achieve consistent processing effect of spherical parts, uneven injection, etc., to achieve consistent processing effect, Prevents arcing and improves service life

Inactive Publication Date: 2010-12-01

HARBIN INST OF TECH

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem that the existing plasma-based ion implantation device and method for rotating workpieces perform plasma-based ion implantation on spherical parts, which has uneven implantation and cannot achieve consistent processing effects for the same batch of spherical parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

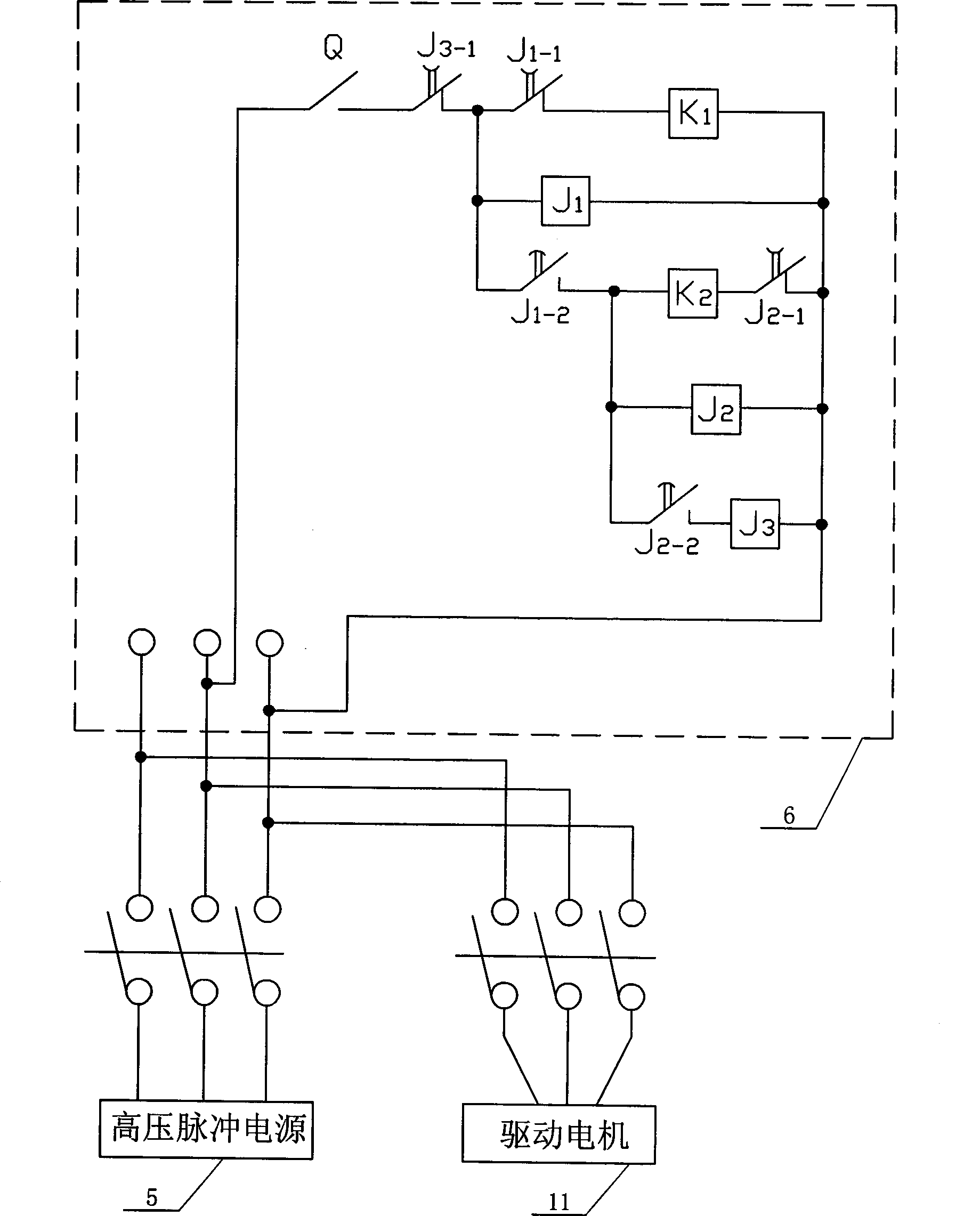

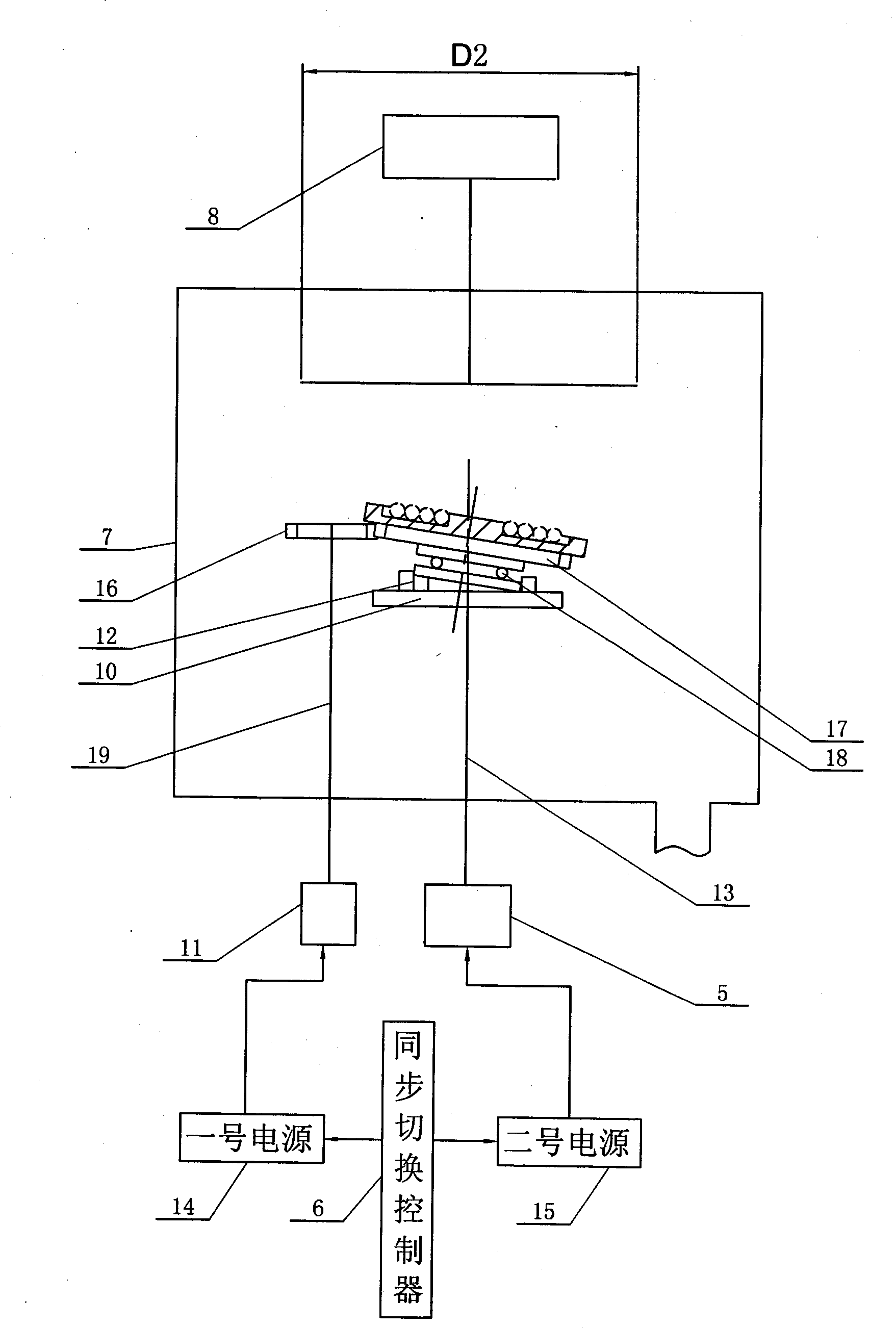

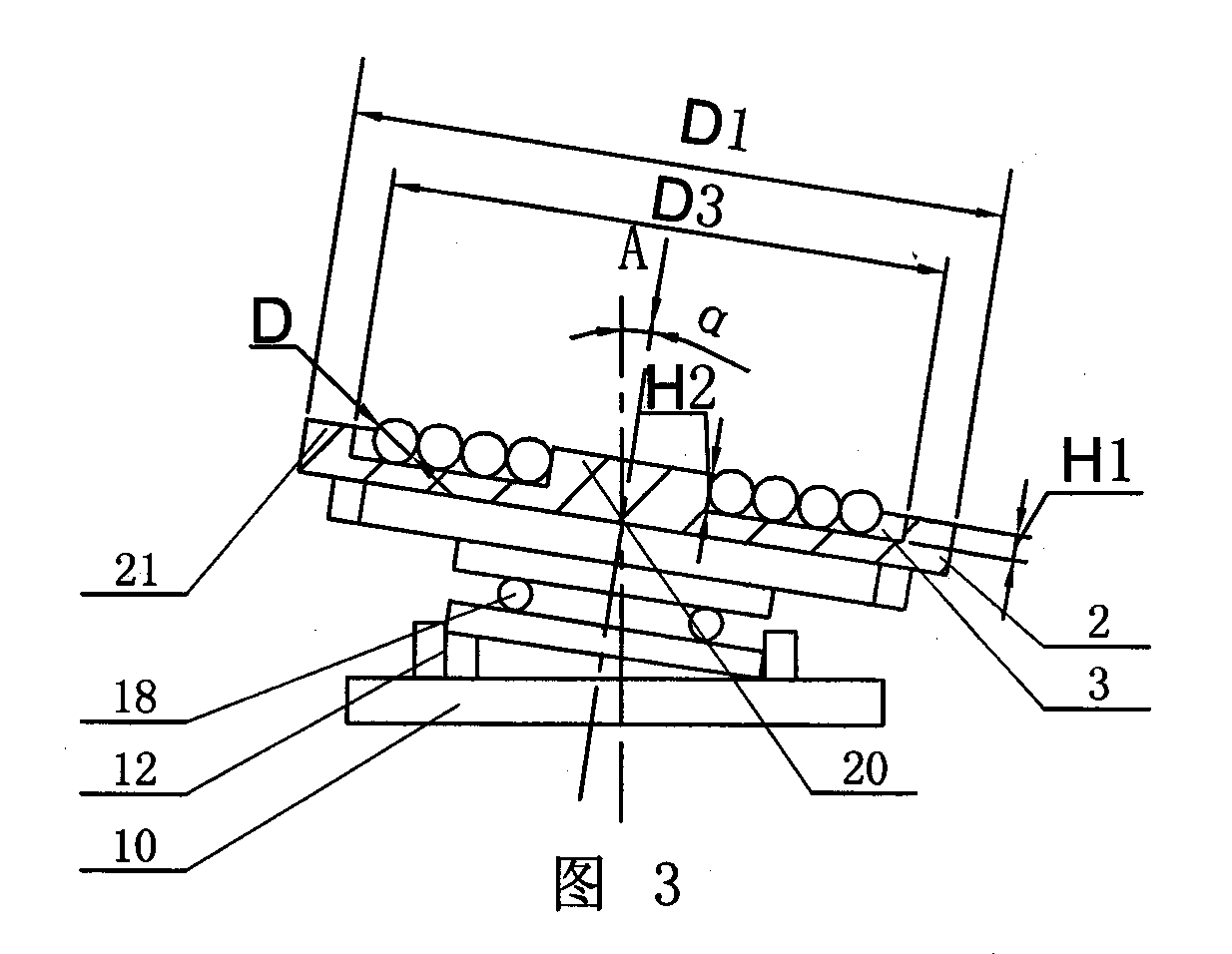

The invention discloses a spherical-component batch plasma-based ion implantation method and a device thereof, relating to a spherical-component plasma-based ion implantation method and a device thereof and aiming at the problem that the plasma-based ion implantation of spherical components which is carried out to spherical components by adopting a device and a method of rotary-workpiece plasma-based ion implantation is uneven and can not realize the uniform treatment effect of the spherical components of the same batch. The method of the invention comprises the following steps: the sphericalcomponents are put in a circular groove of an oblique round plate, the rotation of which is controlled by a driving motor and a gear; the rotation of the driving motor is stopped first, a high-voltage pulse power source is turned on, and after time delay by the high-voltage pulse power source, plasma-based ion implantation is carried out to the spherical components; and the starting and stopping of the driving motor and the high-voltage pulse power source are kept synchronously switched. The device of the invention comprises: a synchronous switching controller provides the driving motor and the high-voltage pulse power source with power by No. 1 and No.2 power sources; an output shaft of the driving motor is fixedly provided with a driving gear which is meshed with a driven gear. The device and the method can uniformly implant the surface irons of the spherical components.

Description

Method and device for batch plasma-based ion implantation of spherical parts Technical field The invention relates to a plasma-based ion implantation method and device for spherical parts, and belongs to the technical field of plasma-based ion implantation. Background technique Plasma-based ion implantation technology can realize low-temperature surface modification of precision parts. Its characteristic is that it does not change the dimensional accuracy of the processed parts, and the temperature can be controlled at room temperature or slightly higher than room temperature, and can be used for all parts in a plasma environment. The surface is implanted at the same time, so this technology can realize batch processing. The basic principle of this technology is to form a plasma space around the workpiece. When a negative high voltage pulse is applied to the workpiece, the plasma is affected by the electric field on the workpiece to form a positive ion sheath around the workpi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C14/32

Inventor 马欣新唐光泽

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com