Non-drill rod boring tool

A technology without drill pipes and drilling tools, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. and other issues, to achieve the effects of reducing power consumption, enhancing engineering adaptability, and improving rock breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

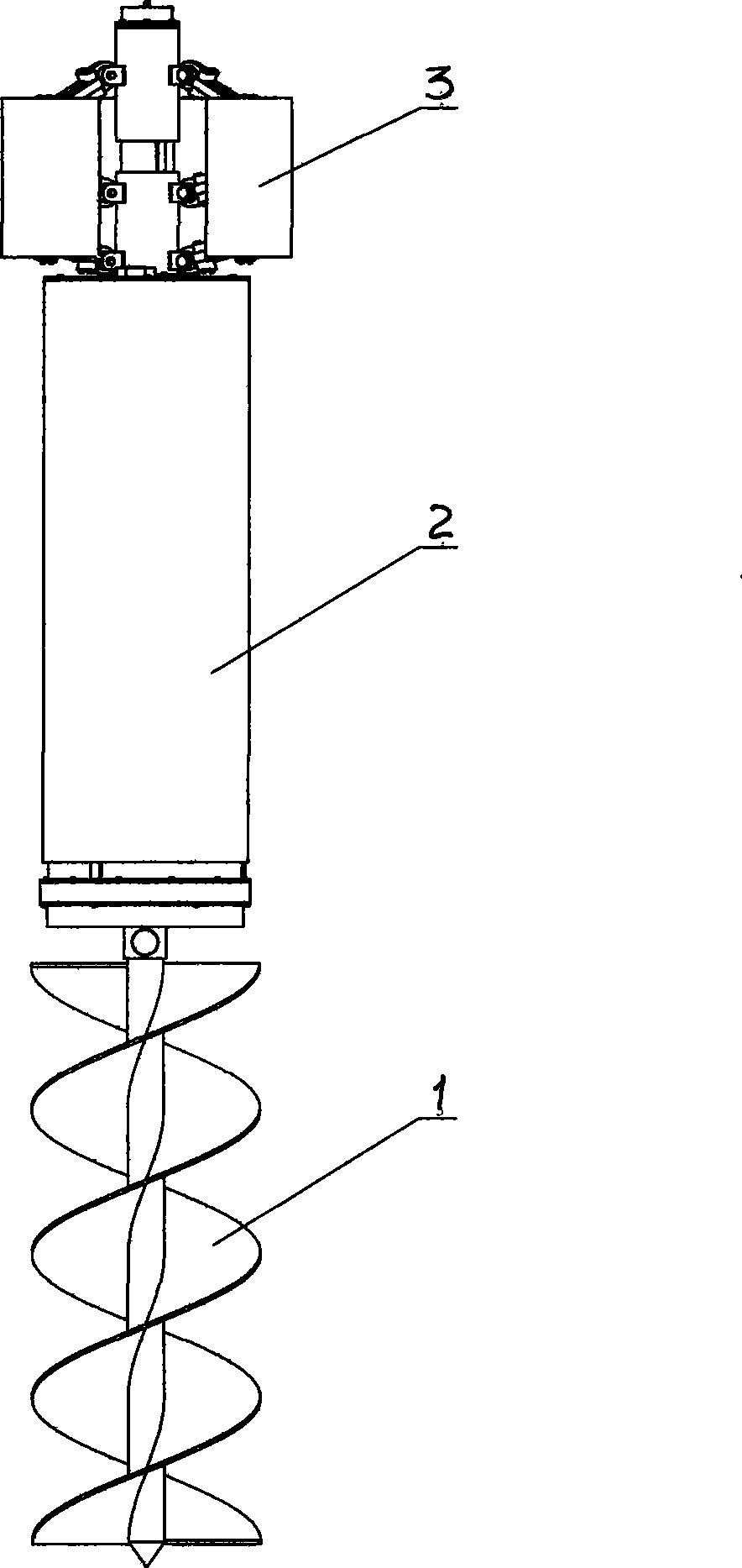

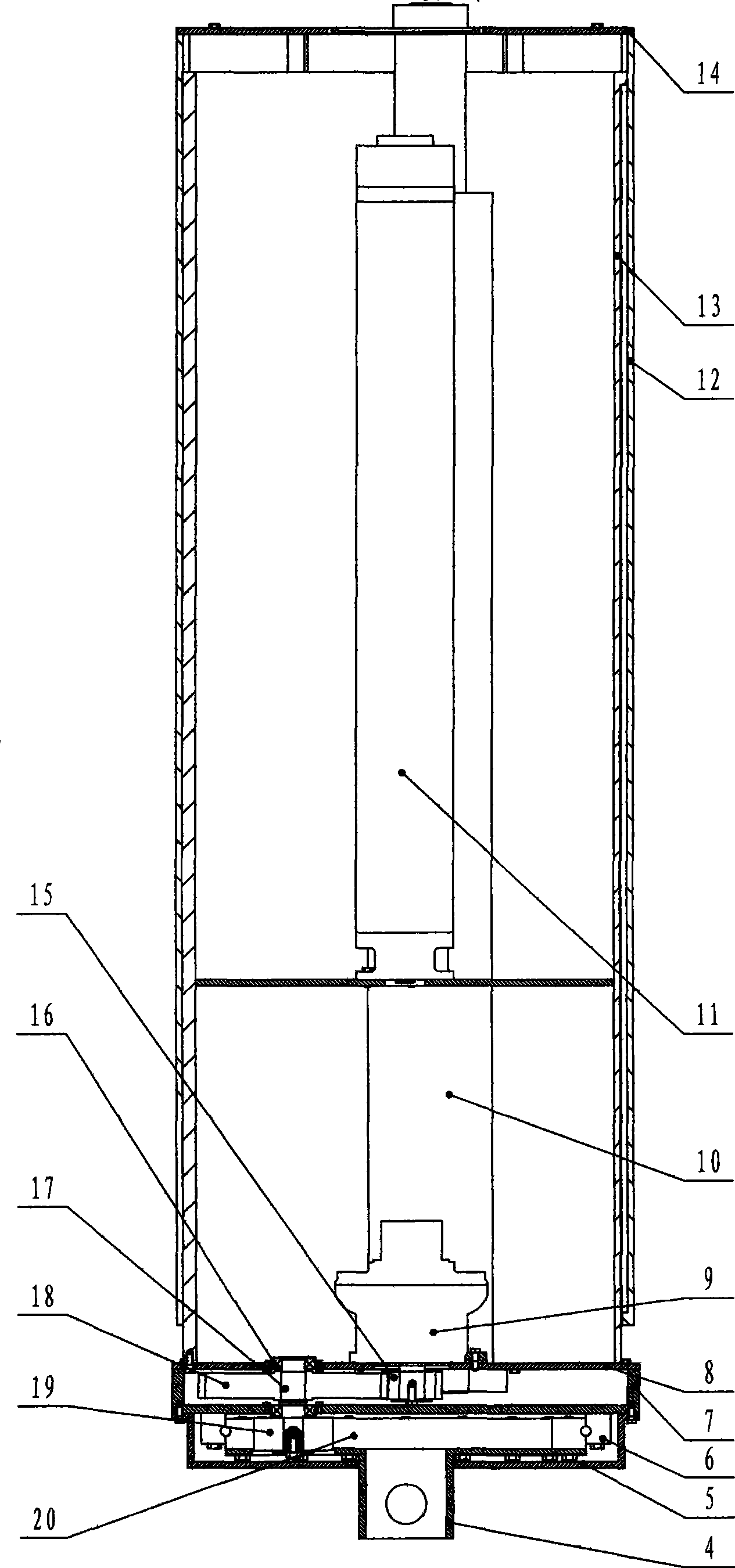

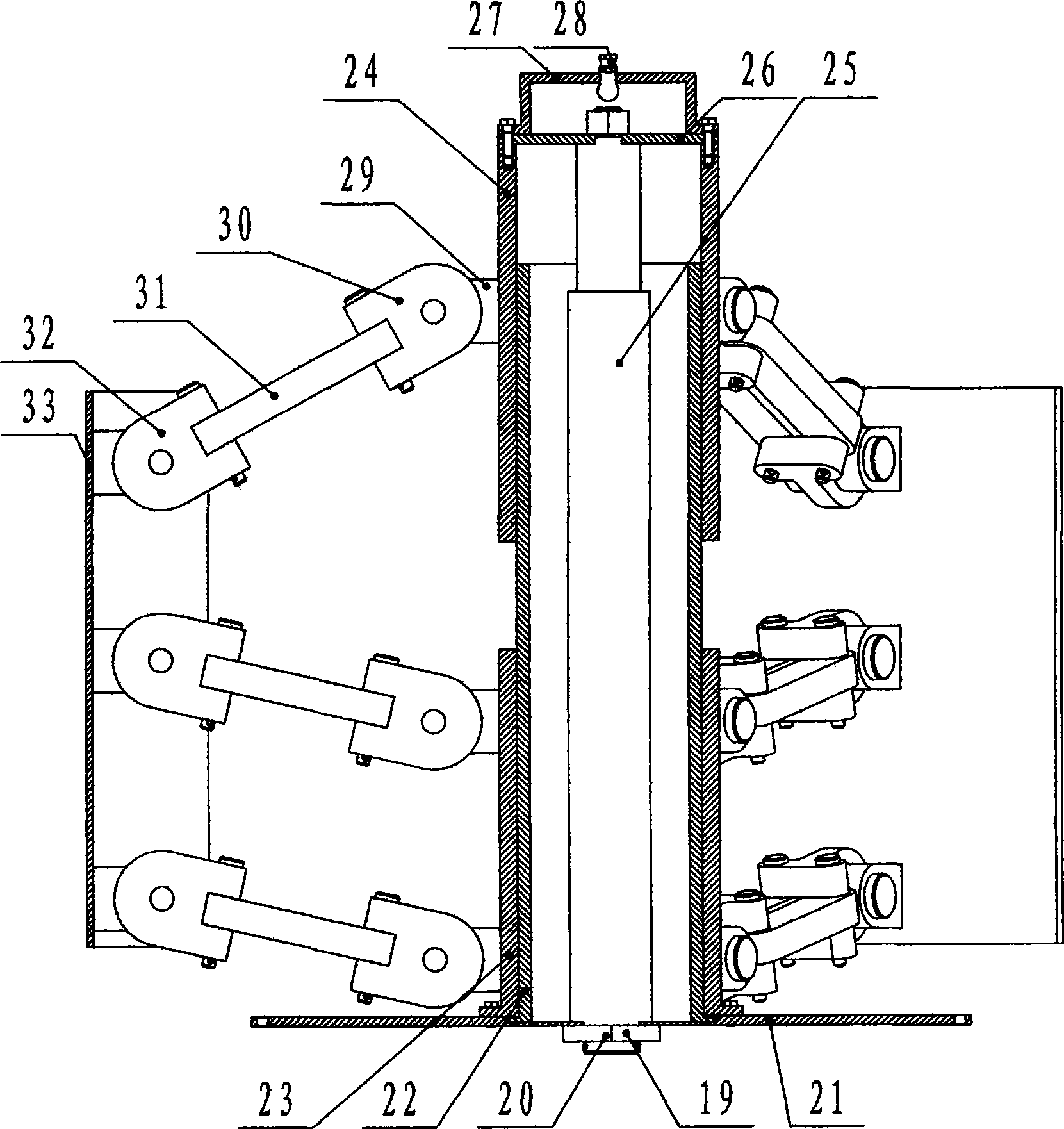

[0011] Depend on Figure 1-Figure 3 It can be seen that the present invention includes a drill bit 1, which is connected to the drill bit 1 and the telescopic pressurization mechanism 2 used to provide power, drilling pressure and drilling stroke for the drill bit 1, and the telescopic pressurization mechanism 2 is used to support the entire drill bit. The tool is fixedly connected with the supporting device 3 for counteracting the counter torque. The drill bit 1 is a rotary bucket, a short screw, a grab bucket or an impactor. The structure of the telescopic pressurizing mechanism 2 is that an inner sliding sleeve 13 is placed inside the cylindrical outer sliding sleeve 12, and a motor 9, an inner pressurizing oil cylinder 10 and a submersible motor 11 are fixed inside it, and the upper end of the outer sliding sleeve 12 is Connect the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com