Fine observation mechanical test system containing gas coal rock

A micro-mechanics and test system technology, applied in scientific instruments, material analysis by optical means, instruments, etc., can solve problems such as single test and test methods, and achieve the effects of wide observation range, good reliability and convenient debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

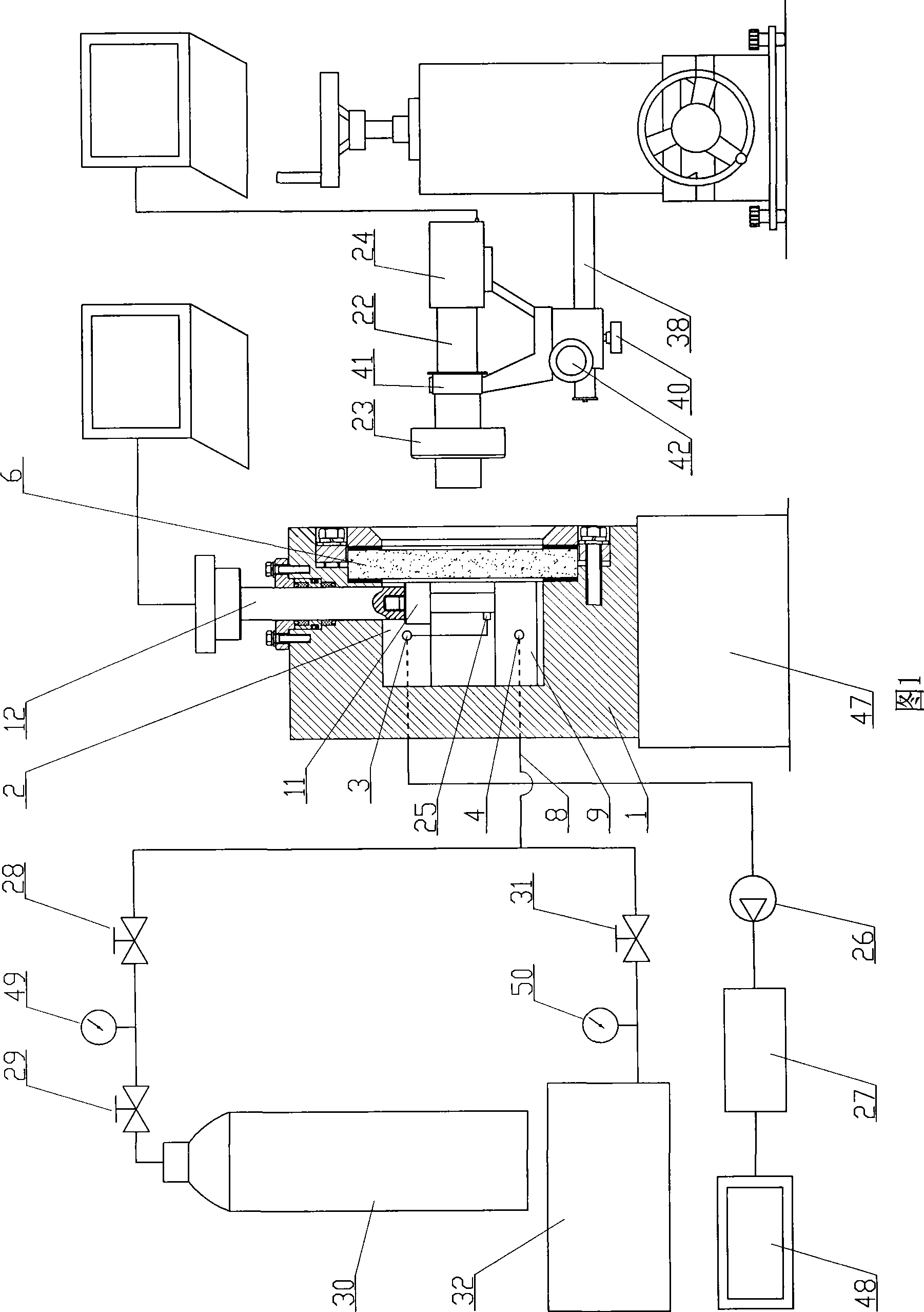

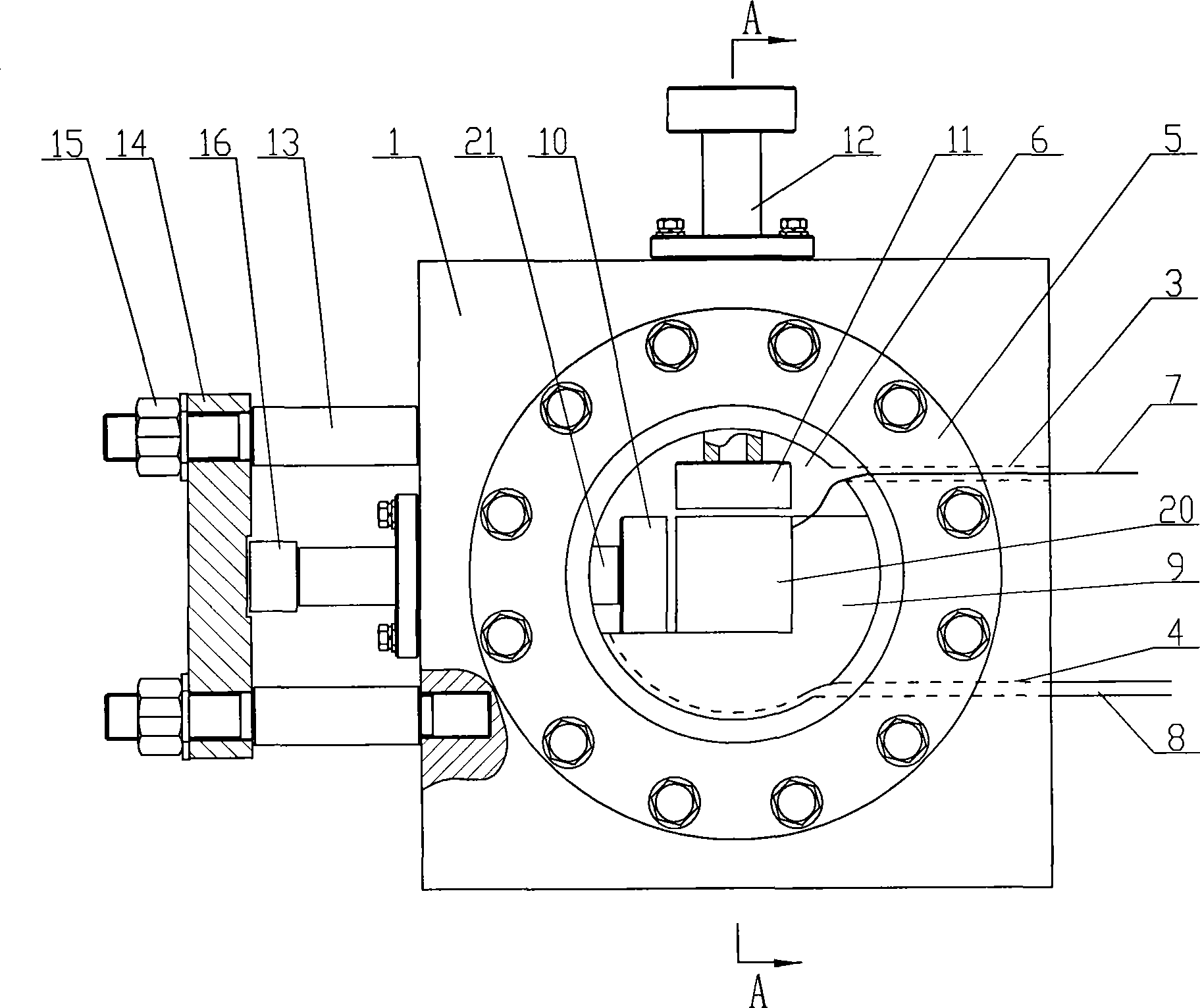

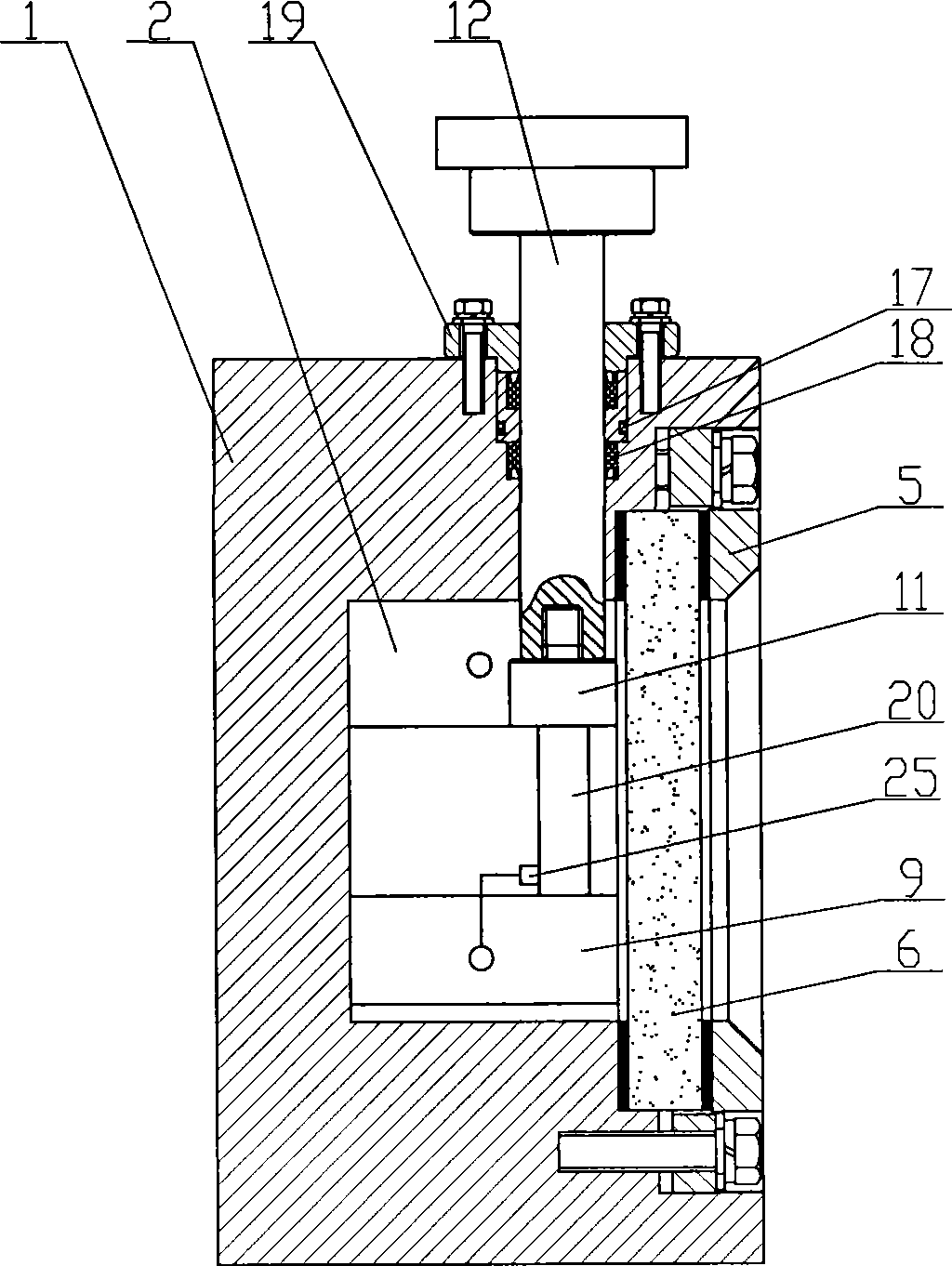

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0034] Such as figure 1 , figure 2 and image 3 As shown, the experimental body 1 is a cuboid structure, placed on the rock rigidity testing machine 47, and a test chamber 2 is opened on the experimental body 1. The opening of the test chamber 2 is located on the front of the experimental body 1, and the test chamber 2 is circular. And it is in the shape of a step with a small inside and a big outside. The transparent viewing mirror 6 and the gland 5 are located at the opening of the test chamber 2, that is, in the large-diameter section, wherein the transparent viewing mirror 6 is disc-shaped, and the inner surface of the transparent viewing mirror 6 is limited by the step surface in the test chamber 2. The transparent mirror 6 and the test body 1 are sealed by an O-ring, and the gland 5 is in the shape of a ring, and the gland 5 is covered on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com