Electric arc stud welding waveform detection device

A waveform detection and stud welding technology, which is applied in the direction of measuring devices, arc welding equipment, welding equipment, etc., can solve the problems of increased detection workload, waste, and inability to detect and evaluate welding quality, so as to overcome the problem of missed detection and avoid Delay, rapid detection and evaluation of the effectiveness of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

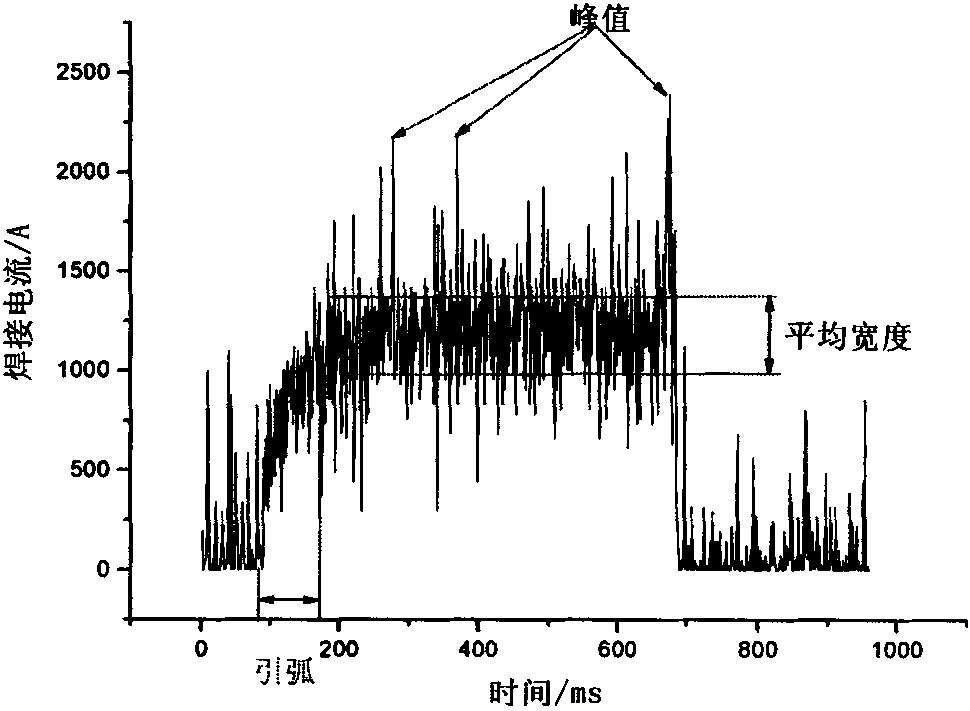

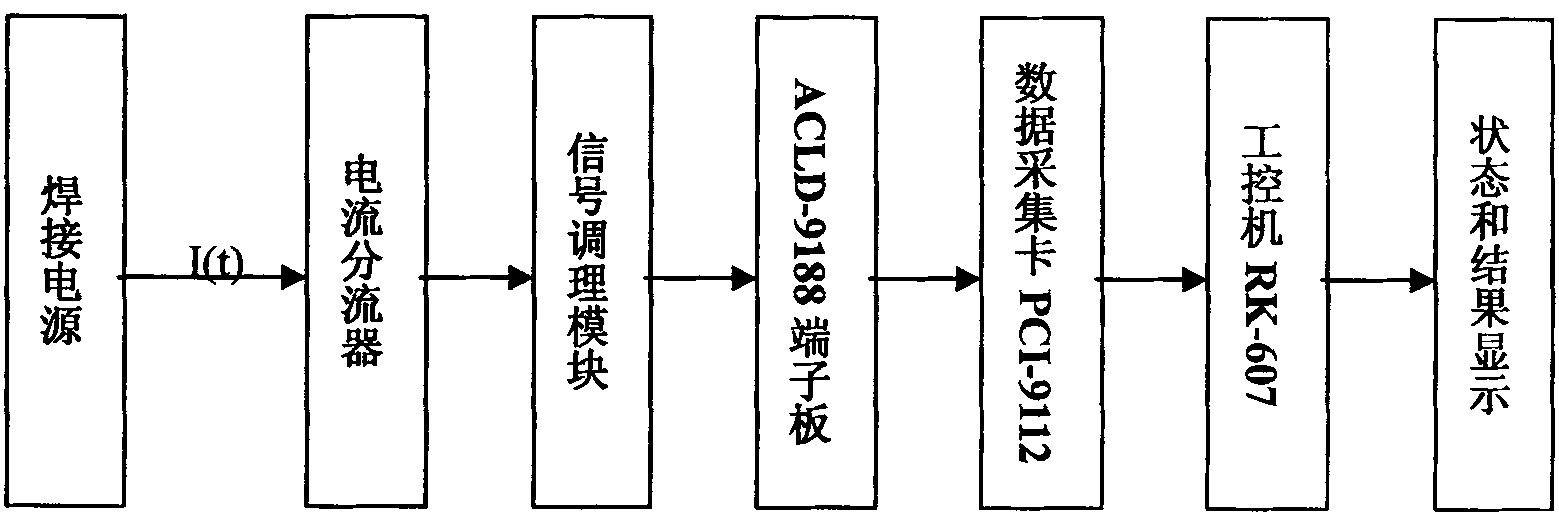

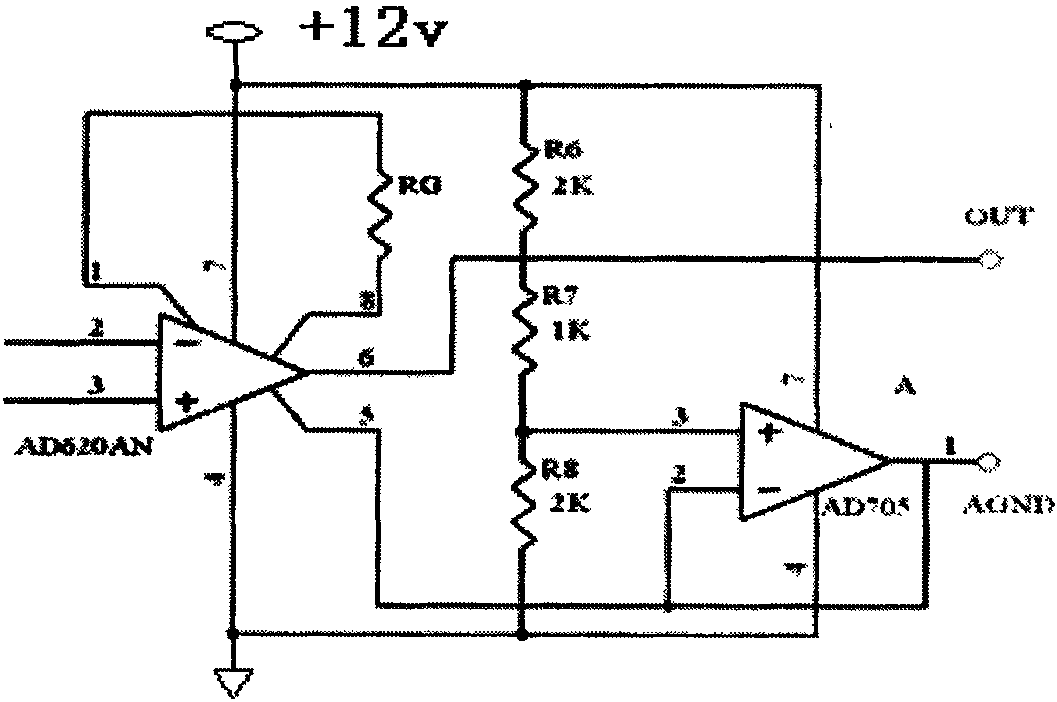

[0038] The arc stud welding waveform detection device and its quality evaluation method of the present invention include a real-time collection and processing system for current waveforms and a defect waveform evaluation method. Its special feature is that the messy waveform in the stud welding process is reasonably and effectively processed by hardware and software methods, and the real-time judgment of welding quality is realized by analyzing the key signals in the current waveform. The hardware waveform acquisition and processing device includes a current shunt, a signal conditioning module, a data acquisition card, and a computer. The software waveform processing system includes a data acquisition module and a data filtering module written in Visual Basic language.

[0039] Among them, the current shunt can obtain the current signal of tens of millivolts during stud welding in the environment of large current and strong magnetic field.

[0040]The signal conditioning modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com