Direct coal liquefaction sewage treatment system and method

A sewage treatment system, a technology for direct coal liquefaction, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

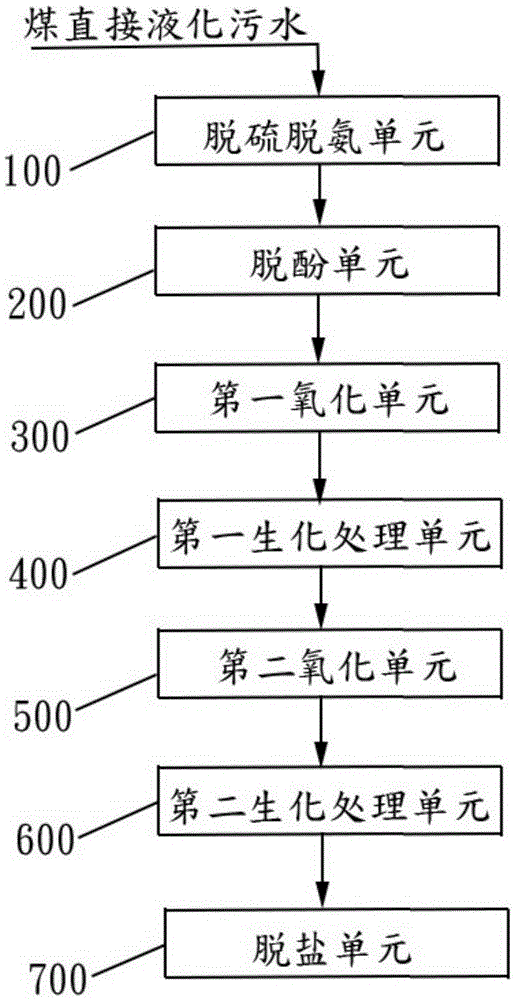

[0180] Sewage W0 is treated by process P1 to obtain sewage W1; then processed by process P2 to obtain sewage W2; then processed by process P3 to obtain sewage W3; and then processed by process P4 to obtain sewage W4; P5 is processed to obtain purified water W5.

[0181] Among them, the main indicators of sewage W4 are shown in Table 3; the main indicators of purified water W5 are shown in Table 4.

[0182] table 3

[0183] project oil BOD5 CODCr Ammonia nitrogen pH suspended matter index ≤5mg / l ≤10mg / l ≤50mg / l ≤5mg / l 6.5~9.0 ≤5mg / l

[0184] Table 4

[0185]

[0186]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com