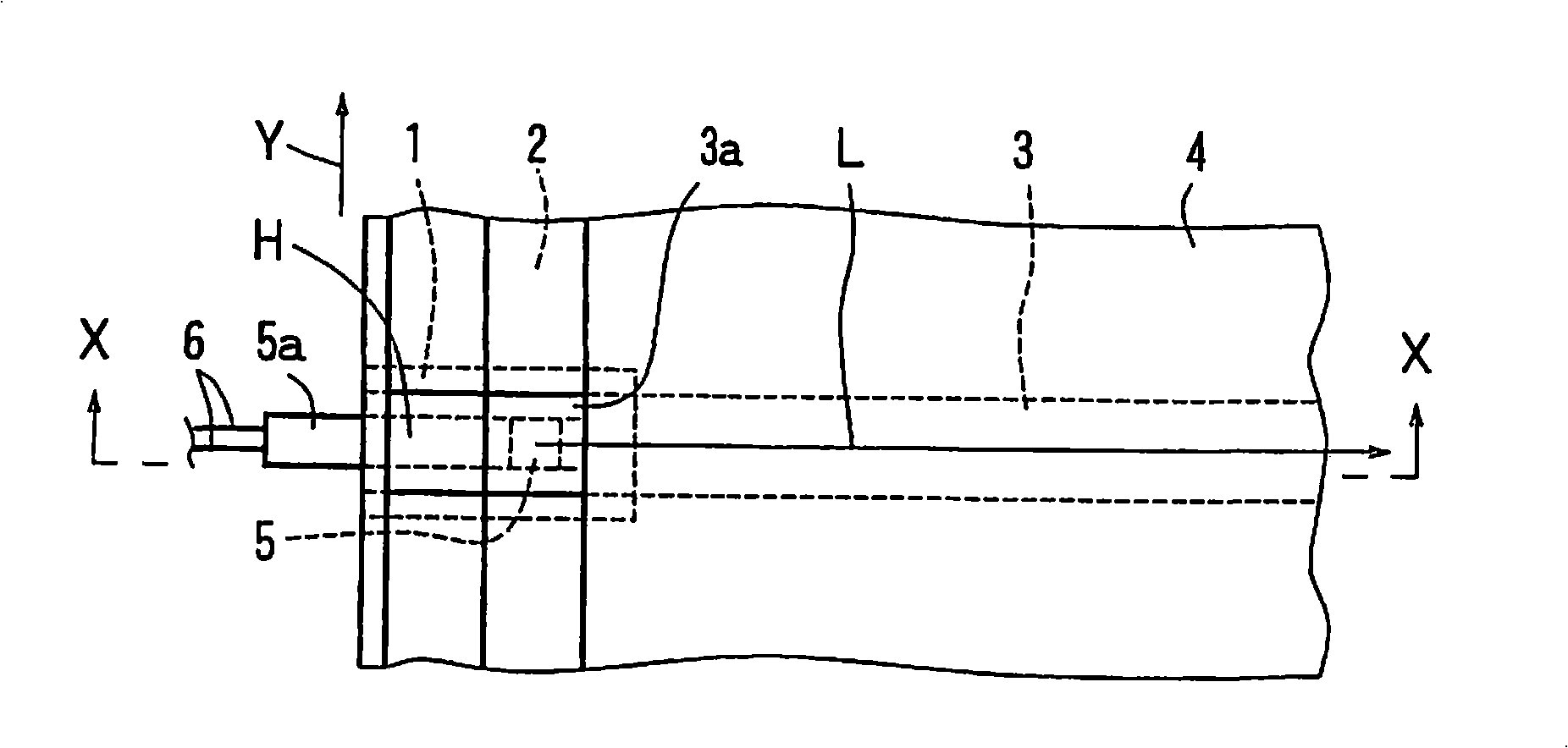

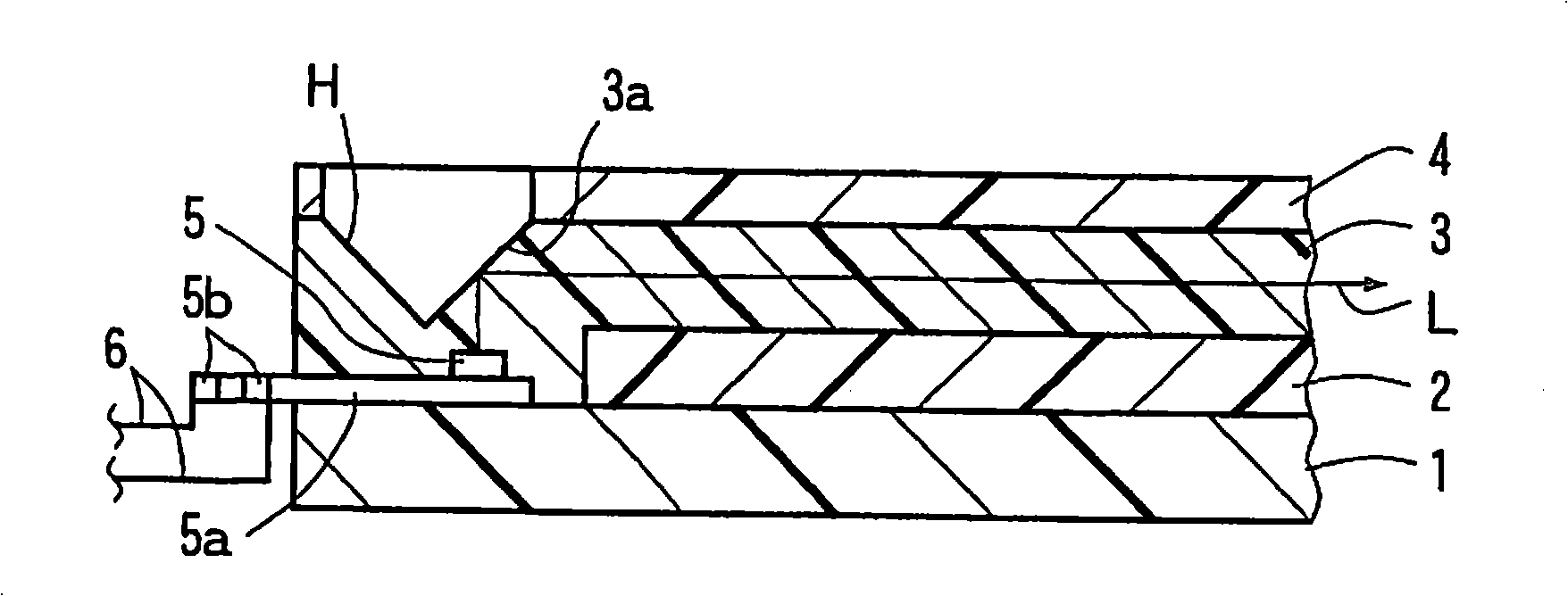

Optical waveguide device and manufacturing method thereof

A technology for the manufacture of optical waveguides and equipment, which is applied in the directions of optical waveguides and optical waveguides, coupling of optical waveguides, and optical waveguides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

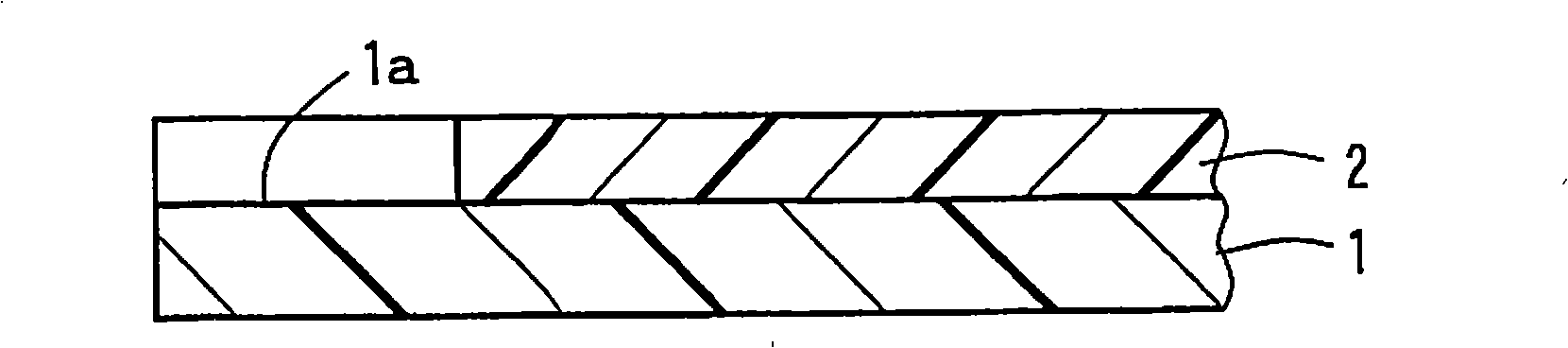

[0042] Forming material of lower cladding layer and upper cladding layer

[0043] 35 parts by weight of 9,9-bis[(4-hydroxyethoxy)phenyl]fluorene diglycidyl ether (ingredient A), 40 parts by weight of 3',4'-epoxy as alicyclic epoxy resin Cyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (manufactured by DAICEL CHEMICALINDUSTRIES, LTD., Celloxide 2021P) (ingredient B), 25 parts by weight of (3',4'-epoxycyclohexane) methyl -3',4'-epoxycyclohexyl carboxylate (manufactured by DAICEL CHEMICAL INDUSTRIES, LTD., Celloxide 2081) (ingredient C), 1 part by weight of 4,4'-bis[bis(β-hydroxyethoxy ) phenylsulfinyl] phenyl sulfide-bis-hexafluoroantimonate 50% propylene carbonate solution (photoacid generator, component D) mixed, thus preparing the lower cladding and surface cladding forming material.

[0044] Core forming material

[0045] 70 parts by weight of the above component A, 30 parts by weight of 1,3,3-tri{4-[2-(3-oxetanyl)]butoxyphenyl}butane, 0.5 parts by weight of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com