Controller for electric vehicle with indention pressing bar

An electric vehicle controller, sawtooth technology, applied to the circuit layout on the support structure, elastic/clamping device, etc., can solve problems such as uneven coating thickness, water seepage through screw holes, and affect the sealing effect, and achieve accurate positioning Performance requirements are reduced, the effect of ensuring sealing and waterproofing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

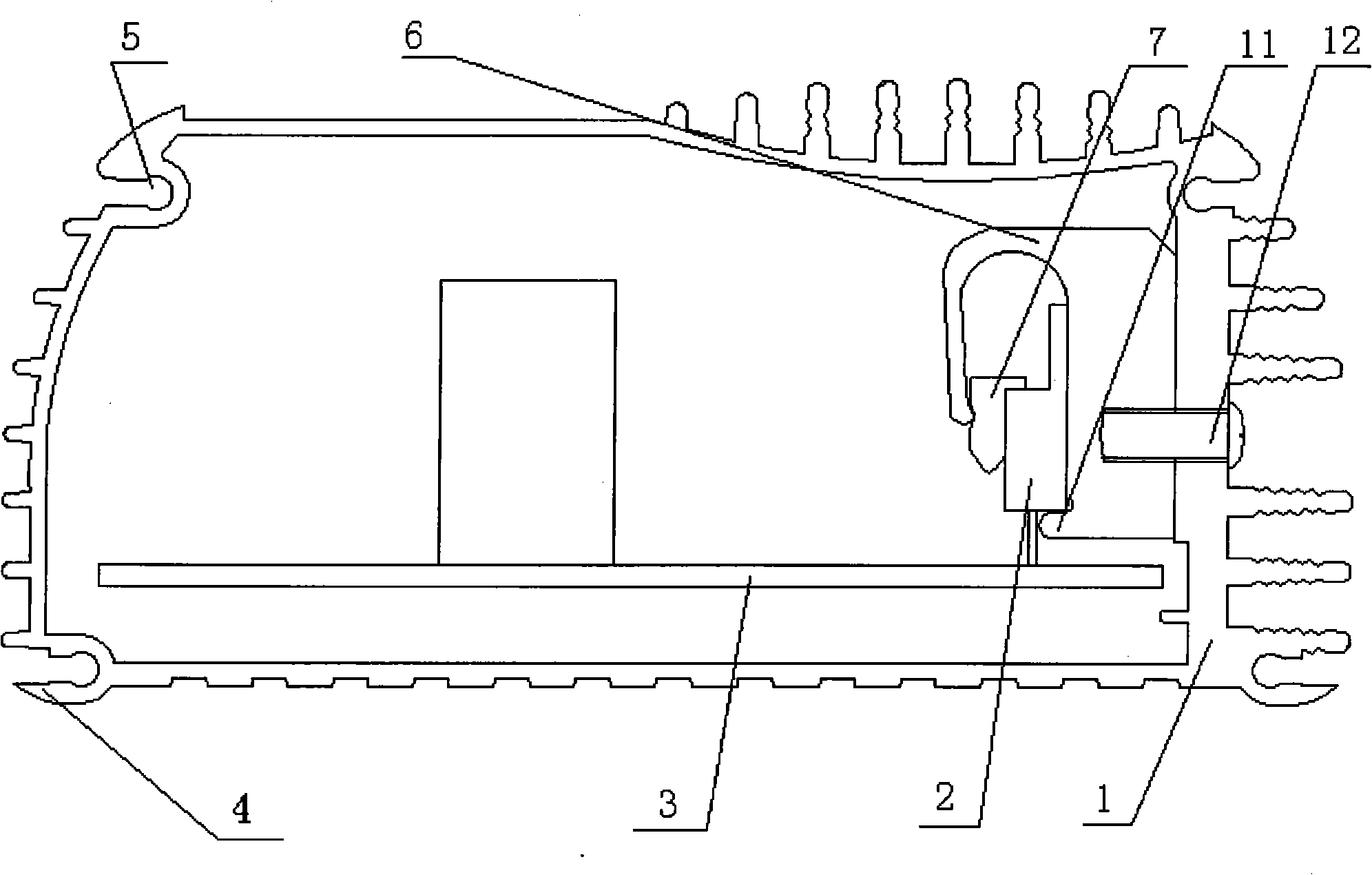

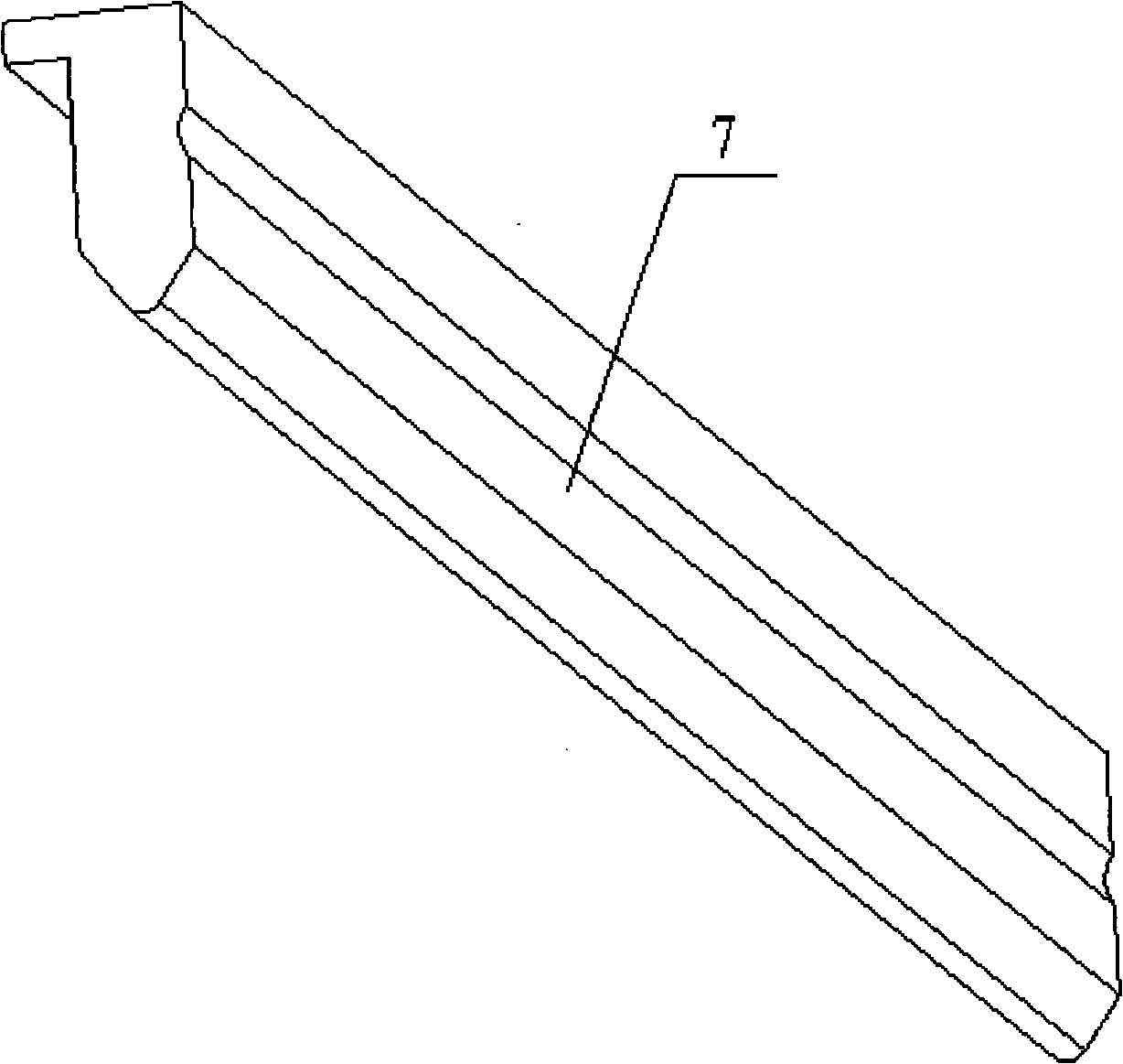

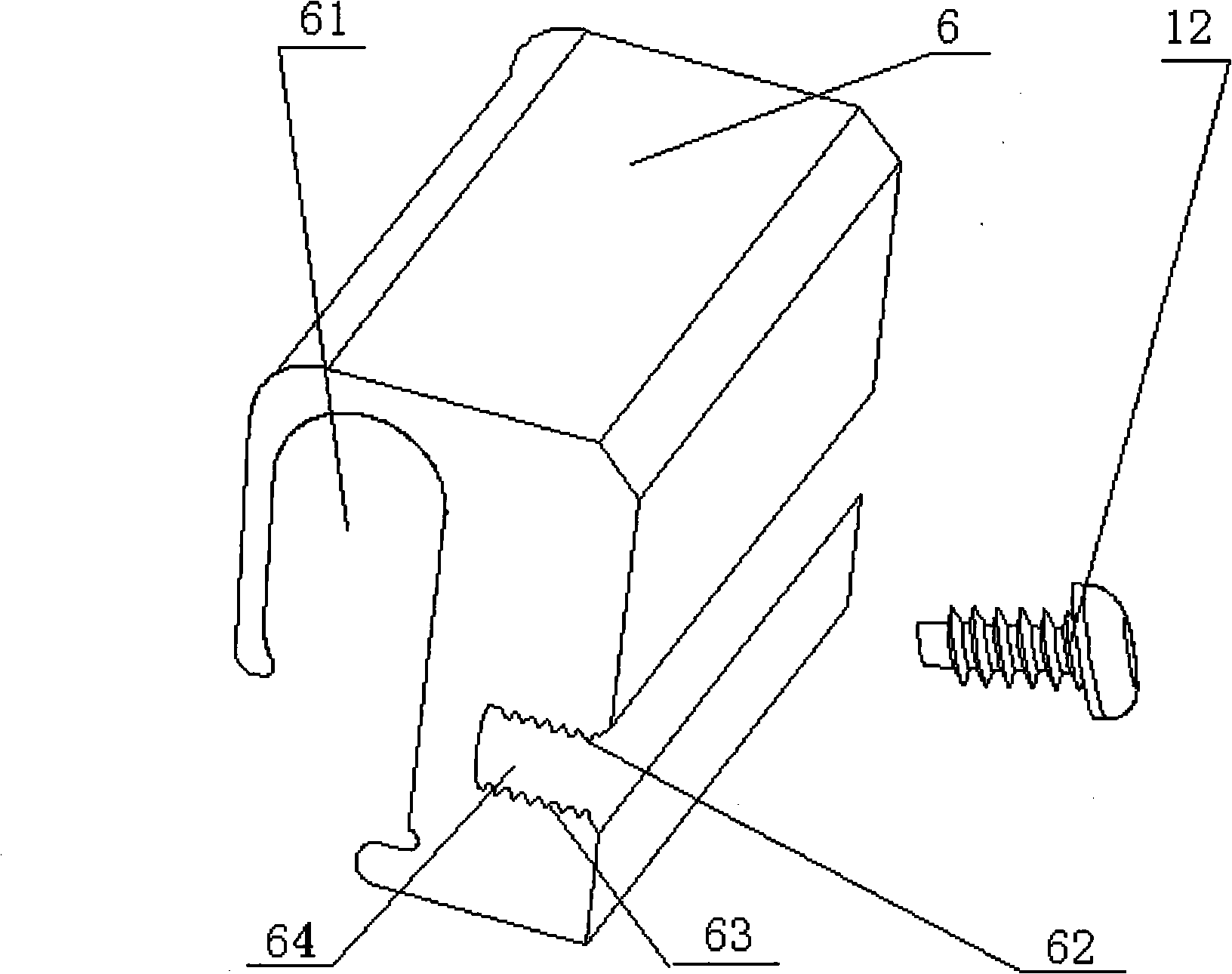

[0033] Such as Figure 1-7 As shown, 1 is the casing, 2 is the power tube, 3 is the circuit board, 4 is the heat sink, 5 is the screw hole, 6 is the bead, 61 is the deep groove, 62 is the upper thread, 63 is the lower thread, 64 is the groove, 7 is a strip wedge, 8 is an end cover, 9 is a card, 10 is an outer cover, 11 is a card platform, 12 is a fastener, 13 is a heat-conducting silicon layer, 14 is an insulating material layer, and 15 is a heat-conducting silicon layer.

[0034] The electric vehicle controller with serrated bead of the present invention comprises the casing 1 of integral cavity structure, circuit board 3 and end cover 8 (when there is outlet hole at end cover 8, can include the card of strip-shaped gap 9 and decorative outer cover 10), the inner cavity of the housing 1 is provided with a bead 6 for supporting the power tube 2 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com