Molten glass supply apparatus and method for producing glass molded article

A technology of molten glass and supply device, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve problems such as poor fluidity of molten glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

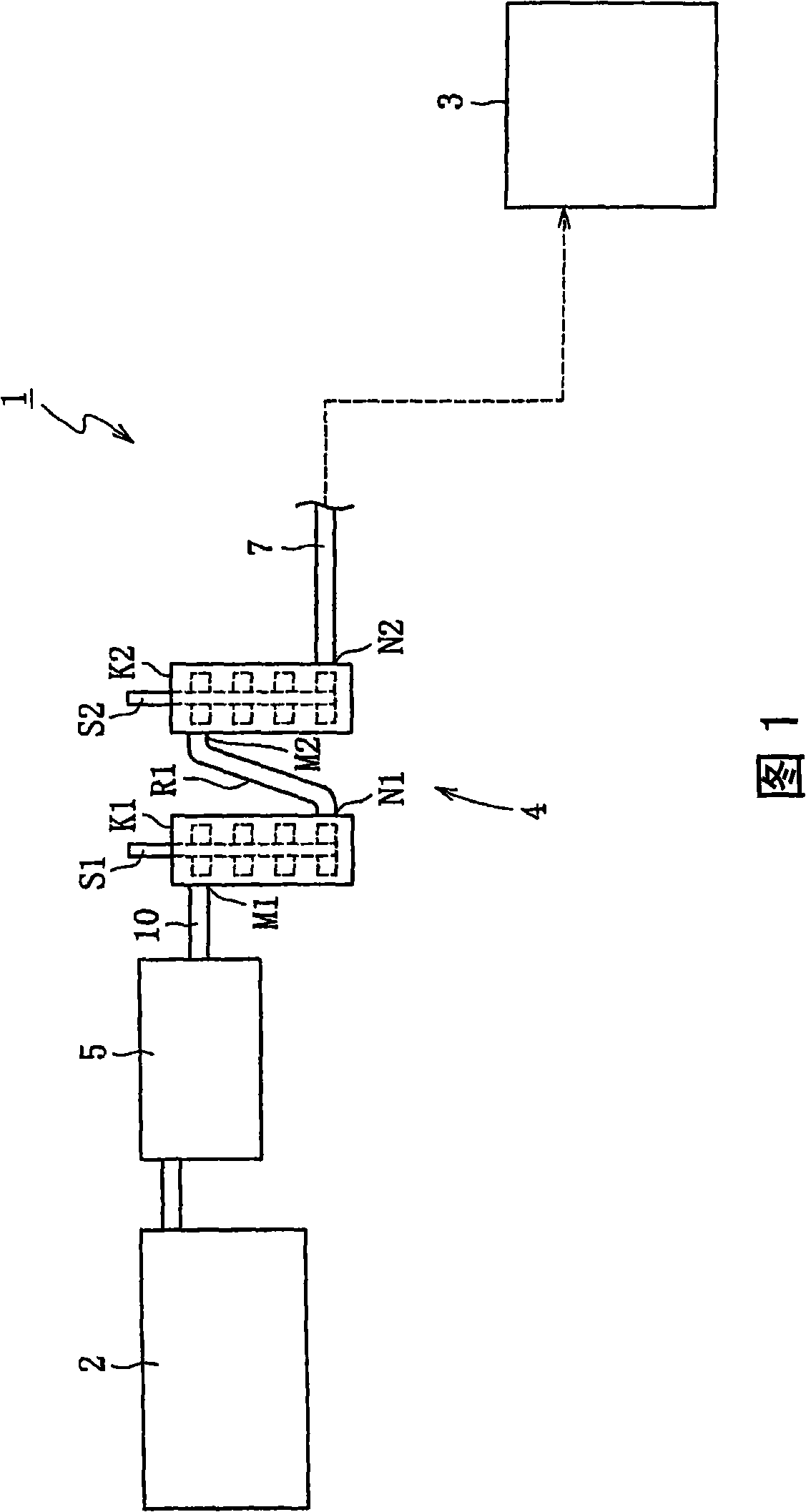

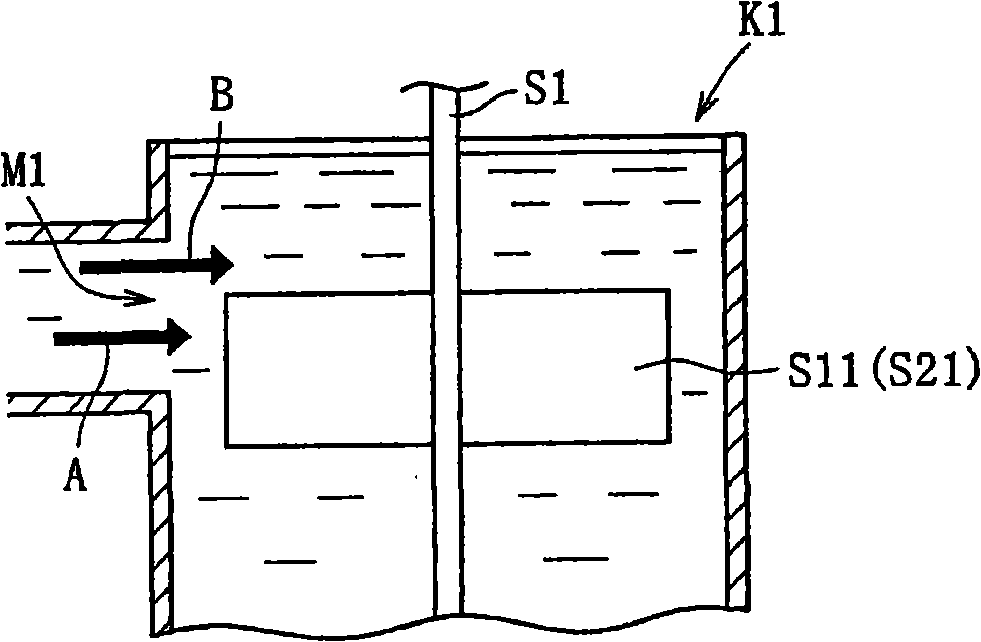

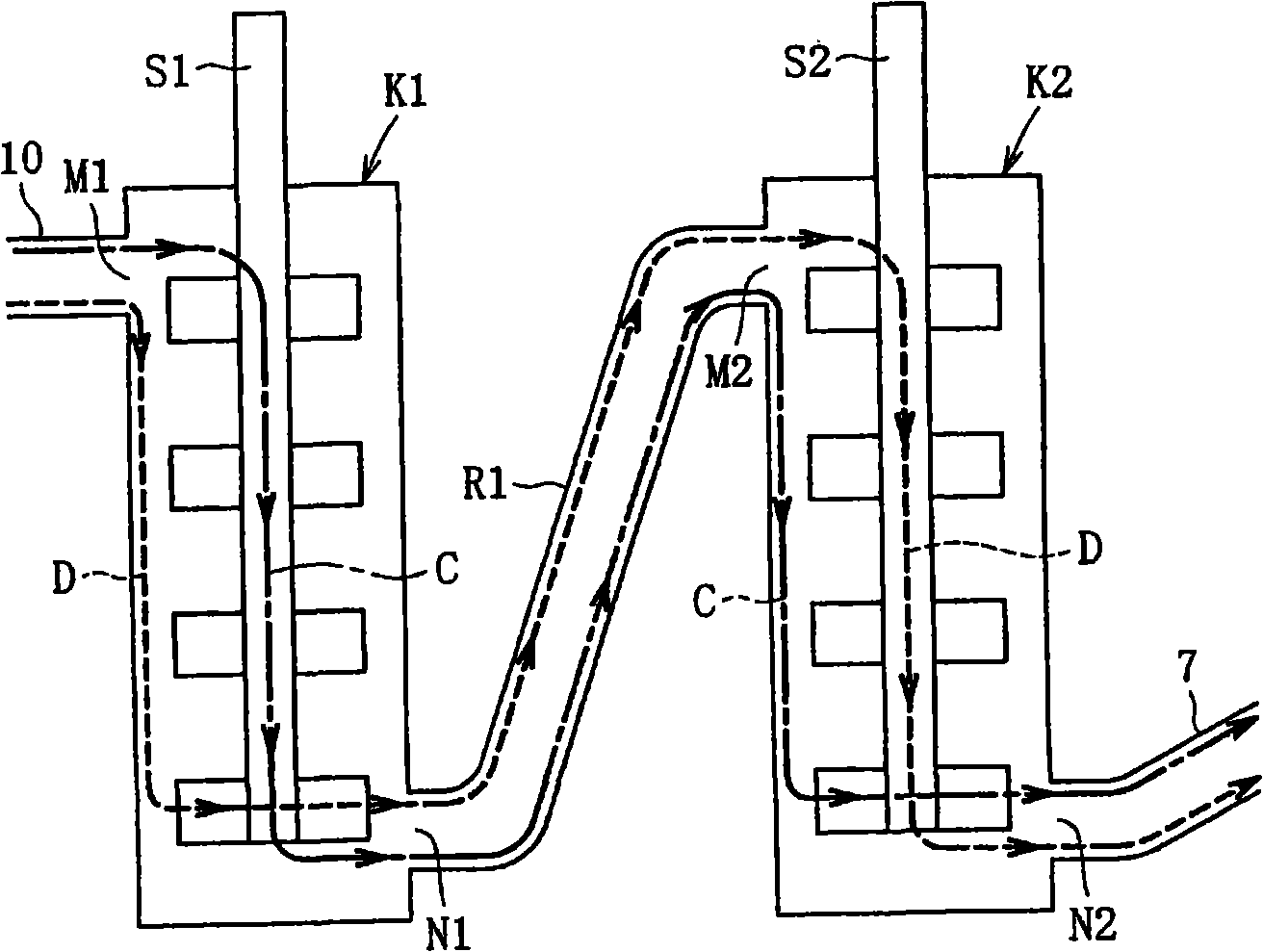

[0117] First, based on FIG. 1, the schematic structure of the molten-glass supply apparatus which concerns on 1st Embodiment of this invention is demonstrated. As shown in Fig. 1, the molten glass supply device 1 is provided with: a melting kiln 2 equipped with an upstream end and a molten glass raw material, and the highly viscous molten glass (having a temperature commensurate with a viscosity of 1000 poises) flowing out from the melting kiln 2 is 1350° C. or higher) is supplied to the forming body of the forming device 3 for forming flat glass through the supply flow path 4 by the overflow wire drawing method. Specifically, the high-viscosity glass supplied here can be used by mass %, for example, containing SiO 2 60%, Al 2 o 3 15%, B 2 o 3 10%, CaO5%, BaO5%, SrO5% composition, the temperature corresponding to the viscosity of 1000 poise is about 1450 ℃ non-alka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com