Polymer film splicing method and device, and stretching method

A technology of polymer film and bonding method, which is applied in the fields of polymer film bonding and devices and stretching, can solve the problems of inability to obtain bonding strength, wrinkles, etc., and achieve the effects of shortening heat transfer distance, preventing pits, and reducing energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

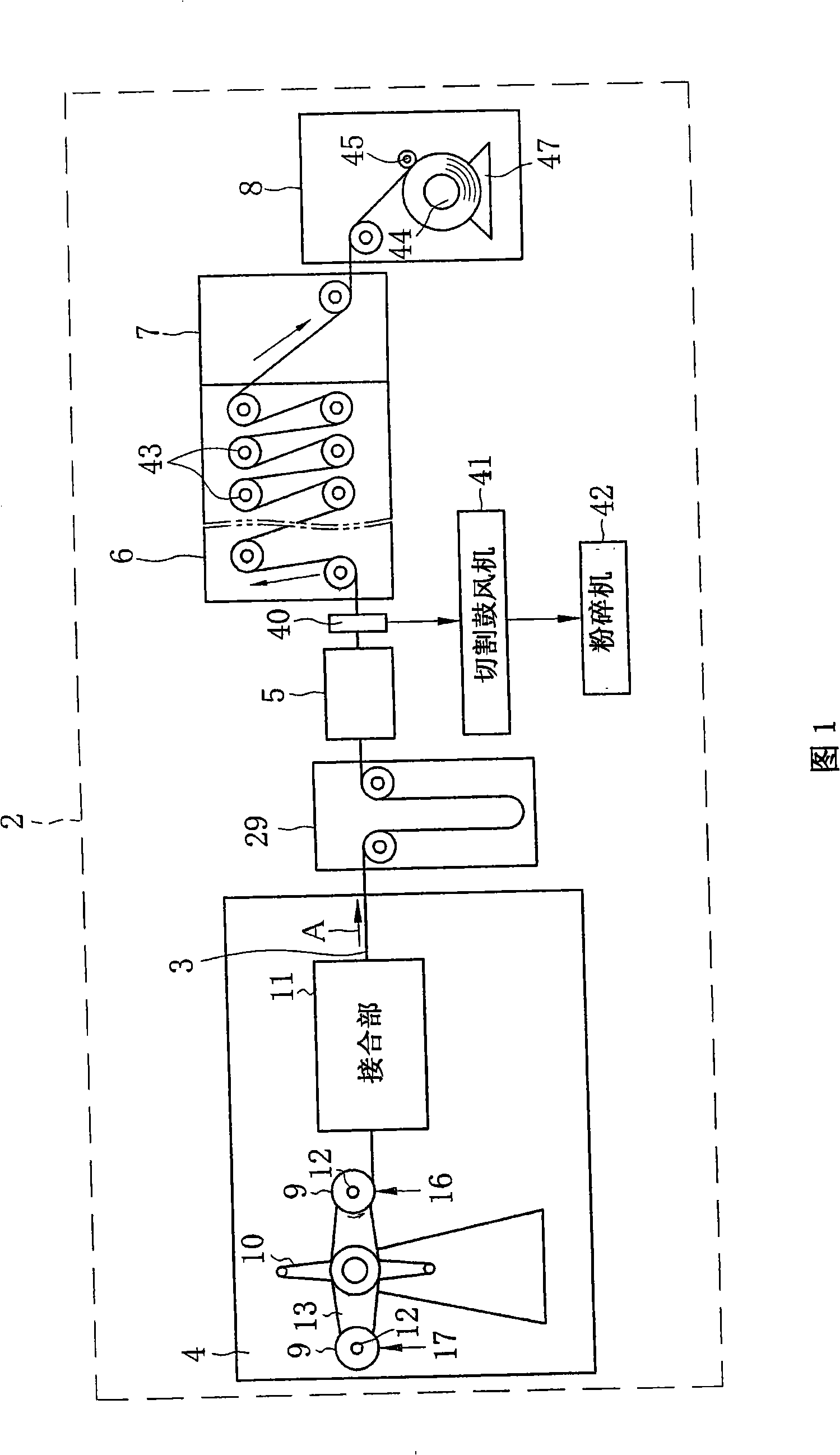

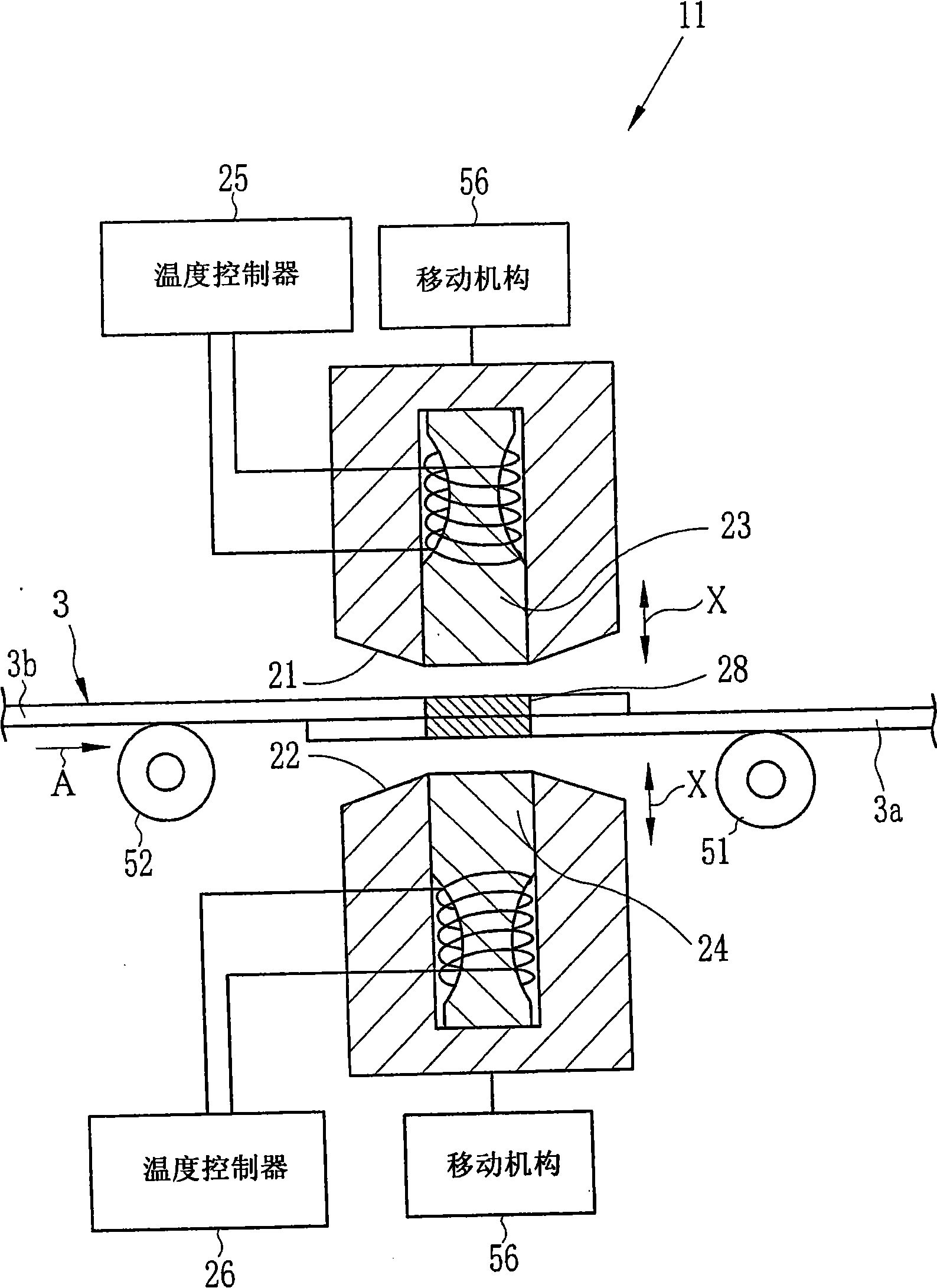

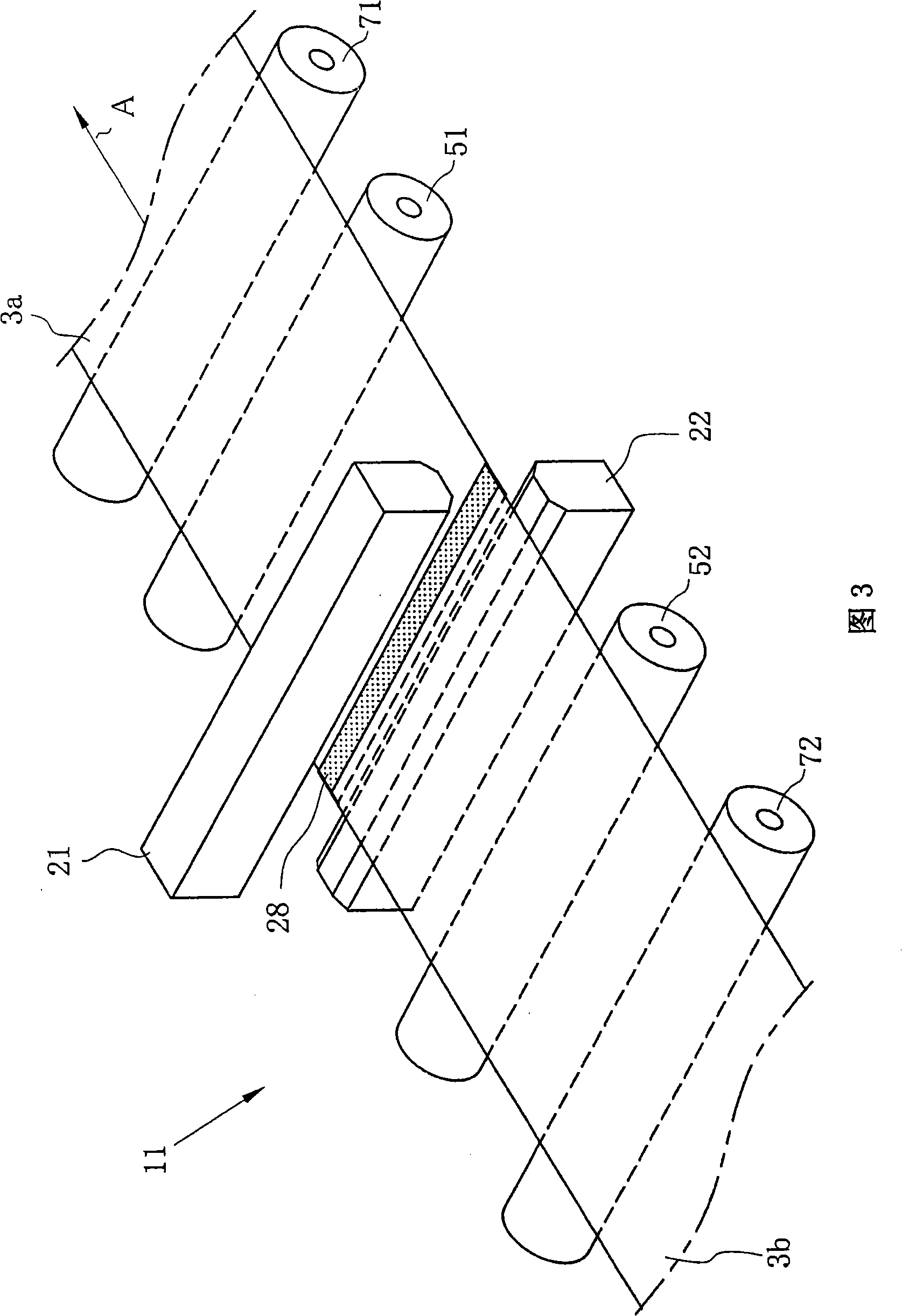

[0034] As shown in FIG. 1 , an off-line stretching device 2 is used to stretch a TAC film 3 (hereinafter referred to as film 3 ), and includes a film supply chamber 4 , a tenter, and Machine part 5, relaxation chamber 6, cooling chamber 7 and winding chamber 8. The film web 9 prepared in the solution casting apparatus is loaded into the film supply chamber 4 . The film roll 9 is obtained by winding the film 3 in roll form around a core. The film 3 is supplied into the tenter section 5 from the film web 9 loaded in the film supply chamber 4 . In the tenter section 5, the film 3 is continuously stretched in the film width direction while being heated. The stretched film 3 is cooled by the relaxation chamber 6 and the cooling chamber 7 . The cooled film 3 is wound up in the winding chamber 8 . In the tenter section 5, the film 3 is stretched by 100.5% to 300% in the film width direction. In each of the film supply chamber 4, the tenter section 5, the relaxation chamber 6, th...

Embodiment approach 2

[0060] Although in Embodiment 1, the front film 3a and the rear film 3b are joined to each other using the fusion machine 20 in the joining section 11, alternatively, as in Figure 8 As shown in , an ultrasonic bonder 50 may be used to bond the front film 3a and the rear film 3b.

[0061] The ultrasonic bonder 50 mechanically vibrates the film 3 , for example, 20,000 to 28,000 times / second with an amplitude of 0.03 mm, to heat and fuse the film 3 . The ultrasonic adapter 50 includes two transducers 57 , a horn 59 and a transmitter 53 . Permanent magnets 54 are disposed between transducers 57 . A coil 55 is connected across each transducer 57 . Transmitter 53 causes coil 55 to drive transducer 57 . The transducer 57 converts electrical vibrations into mechanical vibrations. The horn 59 amplifies the mechanical vibration generated by the transducer 57 to apply energy to the rear end of the front membrane 3a and the front end of the rear membrane 3b mounted on the mounting ba...

Embodiment approach 3

[0063] Although in Embodiment 1, the front film 3a and the rear film 3b are joined to each other using the fusion machine 20 in the joining section 11, alternatively, as shown in FIG. Acetone, one of the film solvents, is used for bonding.

[0064] Acetone was applied by spraying to the bonding area 28 at the rear end of the preceding film 3a, and then the leading end of the following film 3b was placed on the rear end of the preceding film 3a. After that, the rear end of the front film 3a and the front end of the rear film 3b were bonded to each other by acetone in a press-contact manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com