Swing type compressing device of rubbish compressing device

A garbage compression and compression device technology, which is applied in the direction of garbage transmission, garbage collection, storage devices, etc., can solve the problems of high equipment failure rate, poor environmental protection, and reduced work efficiency, and achieve stable work operation, high compression efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

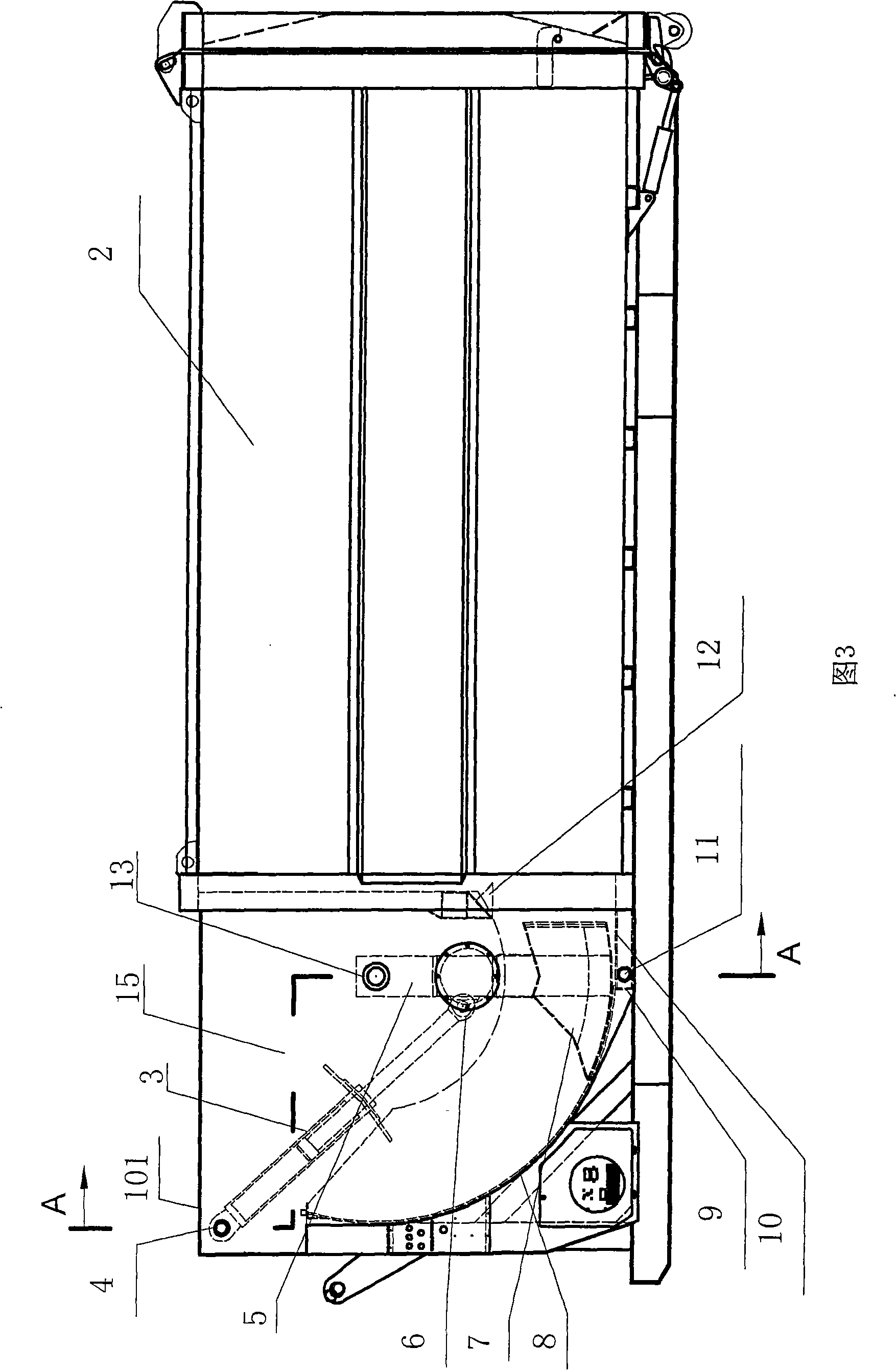

[0020] This embodiment is a one-piece flow type garbage compression equipment using the swing type compression device of the present invention.

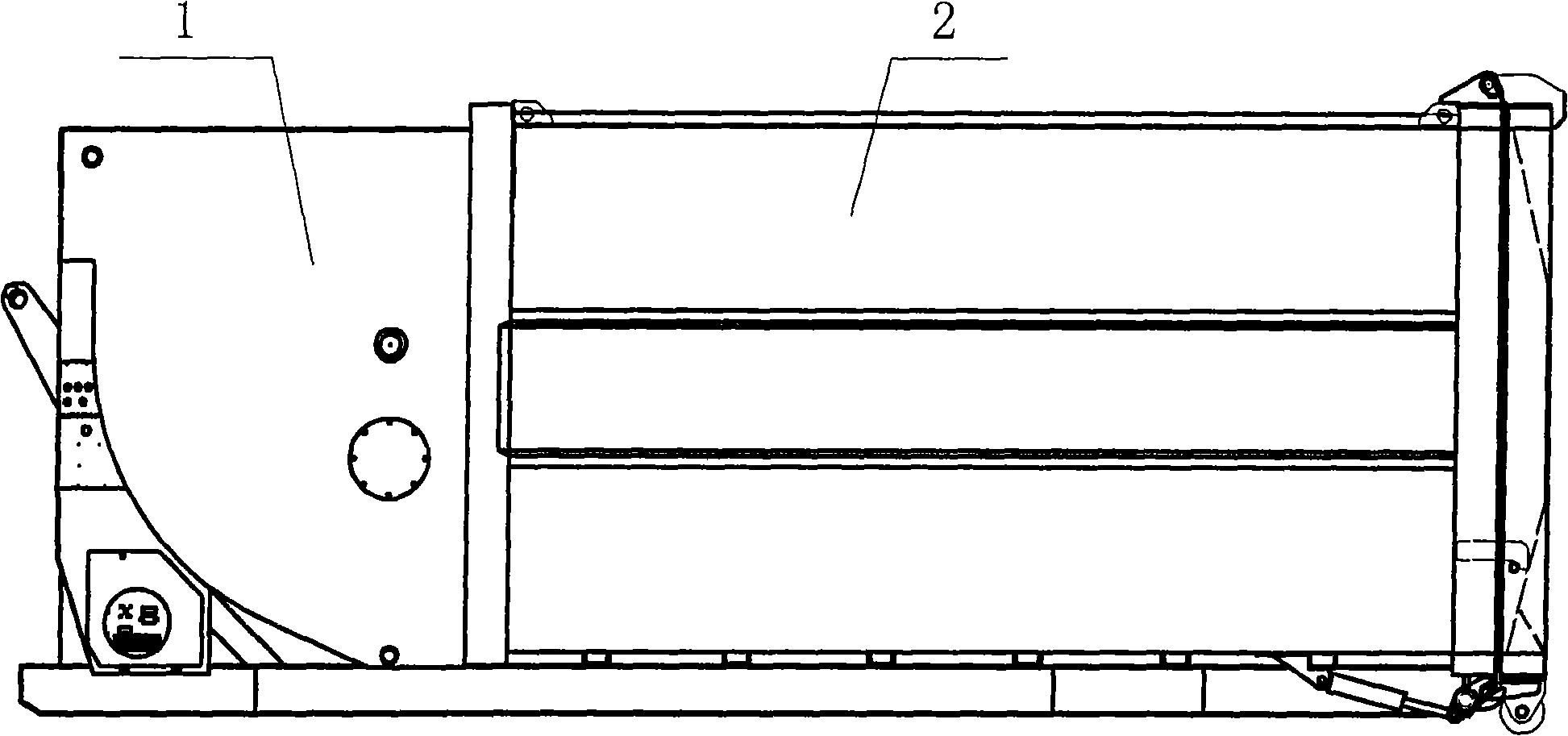

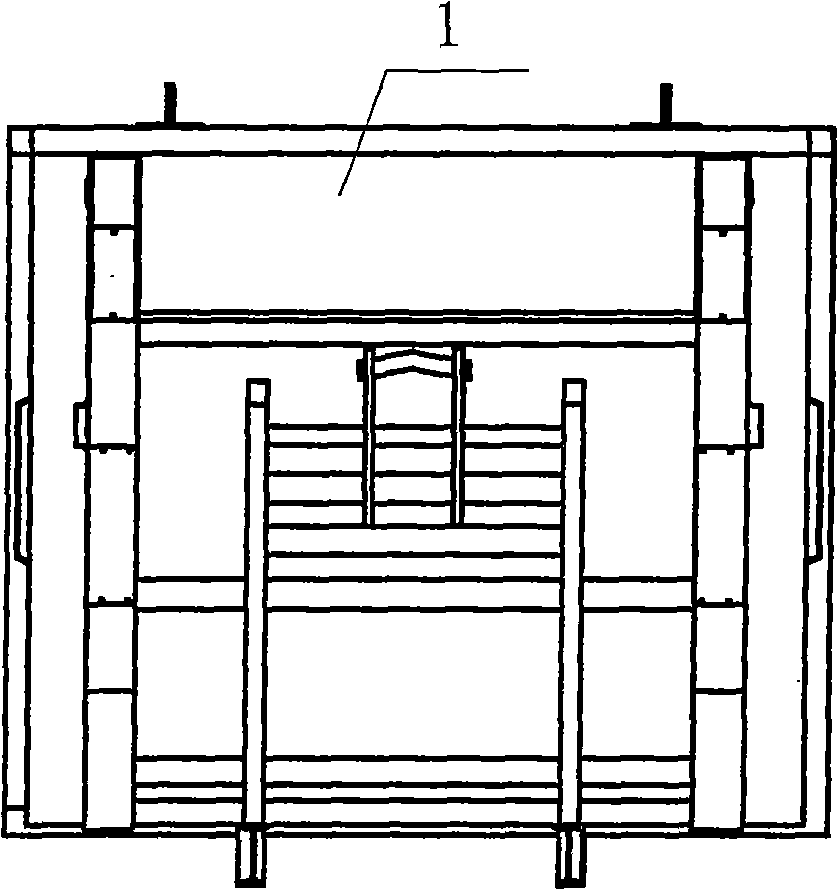

[0021] see Figure 1 to Figure 4 , the present embodiment includes a swing-type compression device 1 and a dustbin 2, and their base plates and connecting plates are respectively designed as one body, and the structure of the dustbin 2 is an existing structure, which will not be described in detail here.

[0022] See Figure 3 to Figure 10 , the swing type compression device 1 in the present embodiment includes a compression box, and a hydraulic cylinder 3 as shown in Figure 8 is respectively arranged on both sides of the compression box, and two pushing head swing arms 5 and A push head 7 and two push head swing arms 5 are respectively located on both sides of the compression box, the rear end of the push head swing arm 5 is hinged on the push head hinge seat 13 through a large pin, and the push head hinge seat 13 is fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com