Bent tube type slag water sealing squeezing slag removal machine

A technology of bent pipe and slag discharger, which is applied in the petroleum industry and the manufacture of combustible gas, etc., can solve the problems of reducing the output of gas-making furnaces, poor working environment, and waste of energy, so as to improve the reliability of safe production and improve the efficiency Working hours, the effect of solving gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

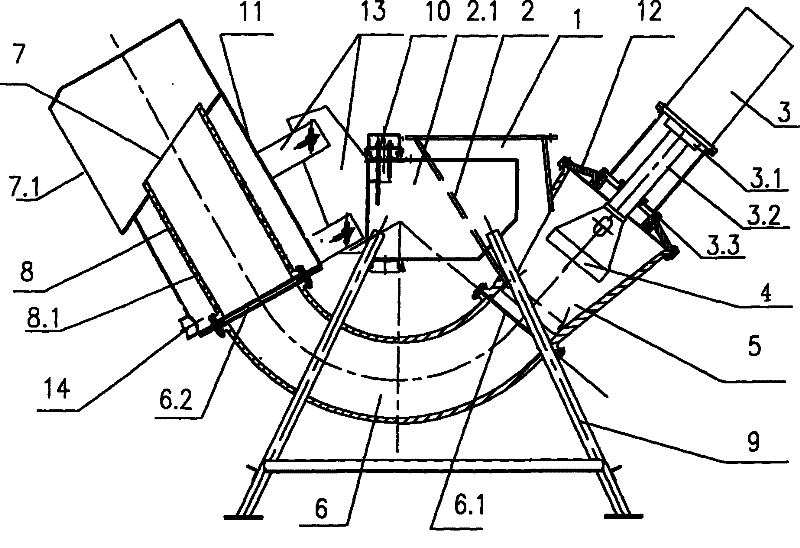

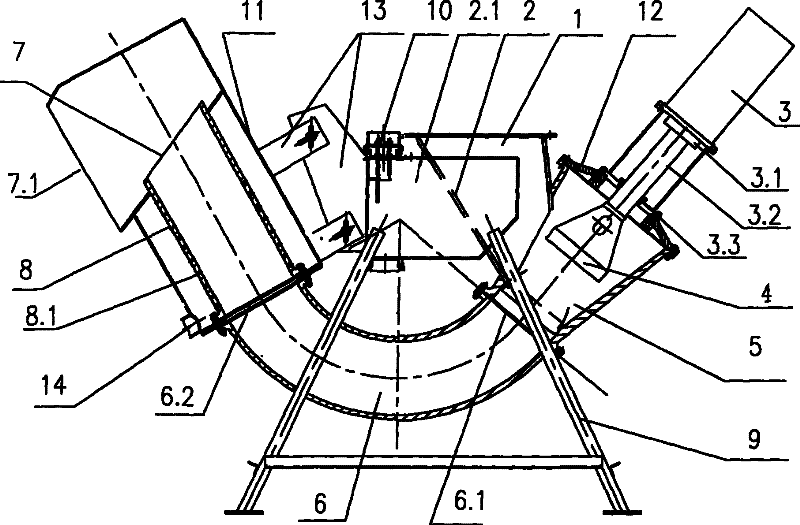

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] The present invention includes a casing, a pressure head and its driving part. The pressure head 4 driven by the driving part is placed in the compression chamber 5; It is connected with the curved casing 6 through a natural transition, and the bend of the curved casing 6 is lower than the compression chamber 5; the other end of the curved casing 6 is the slag outlet 7.

[0022] A water inlet 2 is arranged on the side of the slag feeding funnel. The water inlet 2 is communicated with the replenishing water tank 2.1, so that the water level in the slag-feeding funnel is equal to the water level of the replenishing water tank. A water level controller 10 is arranged in the replenishing water tank, and the control water level is higher than the sealing port 3.3 on the compression chamber 5, so as to ensure that the sealing port 3.3 obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com