Digital absolute code optical fiber liquid level sensor

A liquid level sensor and absolute code technology, applied in the direction of buoy liquid level indicator and other directions, can solve the problems of difficult to work accurately in dynamic conditions, measurement results are easily affected by changes in liquid density, environmental pressure changes, and difficult to achieve high-precision measurement. Measures the effect of improved immunity to interference, high sensitivity and reliability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

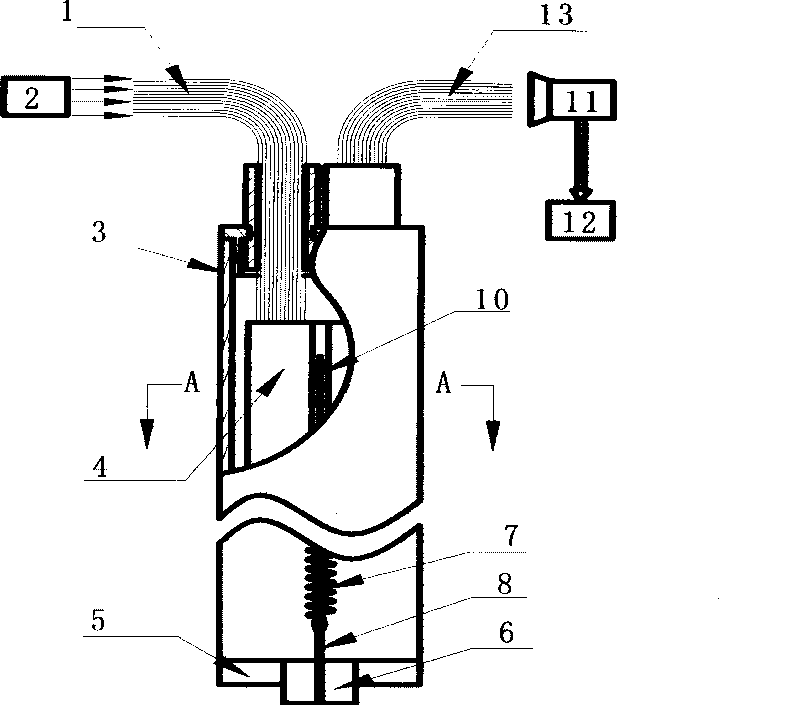

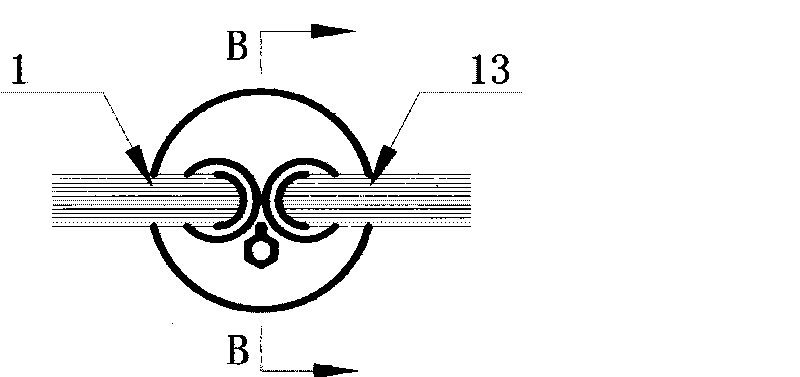

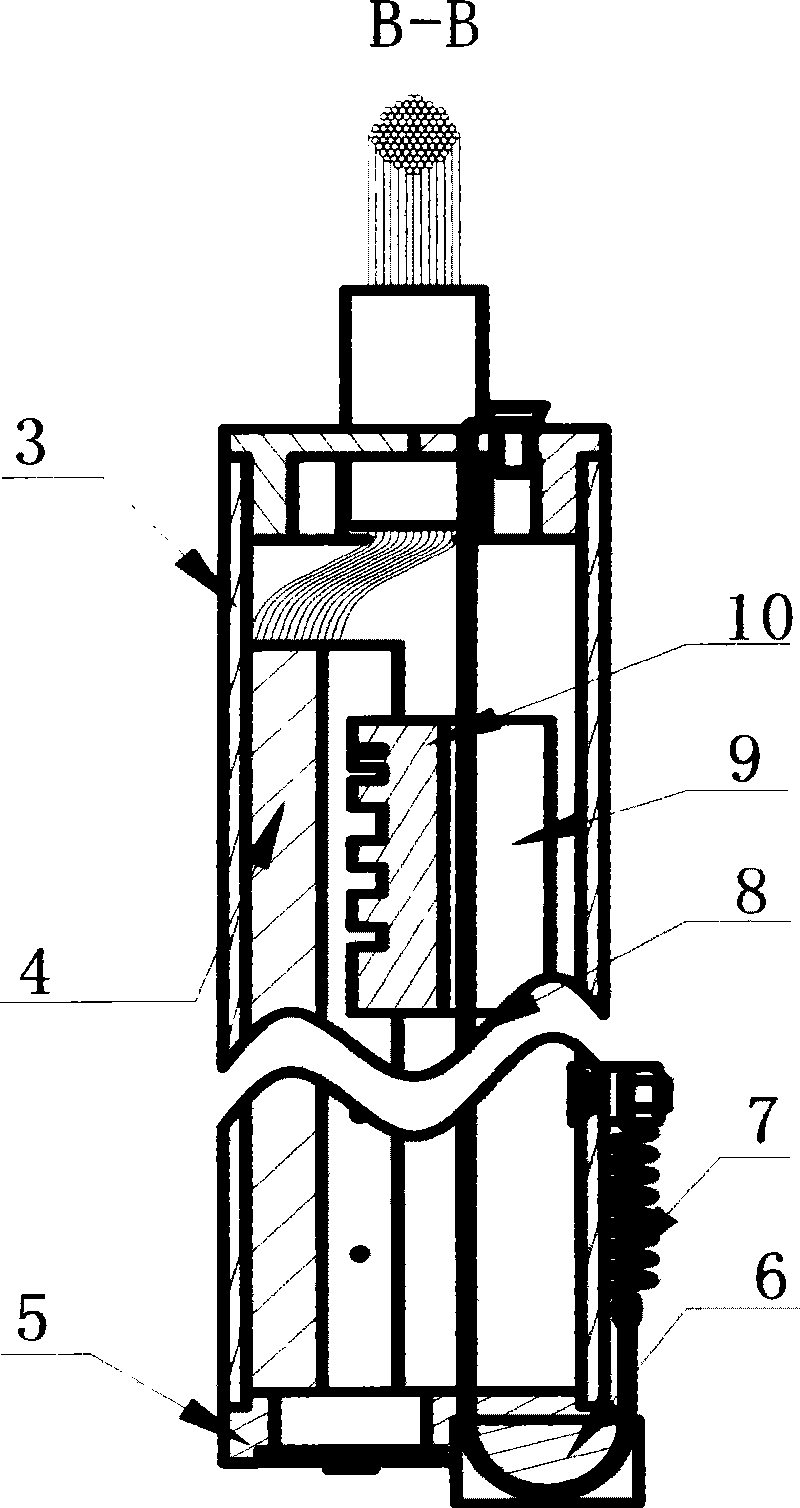

[0026] Example 1: Figure 5 It is required that the baffle can accurately reflect the liquid level, and can achieve the resolution of b / 2. The size of the convex platform in the vertical direction of the two subdivision baffles enables the outgoing optical fiber to obtain the corresponding liquid level signal, and the digital value of the liquid level is obtained by the processing unit. encoded signal.

Embodiment 2

[0027] Example 2: Image 6 It is a four-subdivision baffle structure that requires the baffle to accurately reflect the liquid level and meet the resolution requirements of b / 4. The size of the boss in the vertical direction of the baffle enables the outgoing optical fiber to obtain the corresponding liquid level signal, which is processed by the processing unit. A digitally encoded signal of the liquid level is obtained.

Embodiment 3

[0028] Example 3: Figure 7 It is a ten-subdivided baffle structure design that requires the baffle to accurately reflect the liquid level and meet the resolution requirements of b / 10. The size of the boss in the vertical direction of the baffle enables the outgoing optical fiber to obtain the signal of the corresponding liquid level. The digital coding signal of the liquid level is obtained through the processing unit. The ten subdivision proposed in the third embodiment can obtain a resolution of 1 mm when the distance between optical fiber pairs is 10 mm.

[0029] The above three examples are just an application of two subdivisions, four subdivisions, and ten subdivisions of the present invention. According to different requirements, the baffles can be designed with different boss sizes to perform different subdivisions to obtain the liquid level. Corresponding coding at the exit fiber end. The invention can greatly reduce the number of optical fiber pairs under the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com