X-ray detection machine for giant engineering tyres

An engineering tire and testing machine technology, applied in the direction of using radiation for material analysis, etc., can solve the problem that the moving stroke of the ball head group cannot meet the testing requirements of super-giant engineering tires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The X-ray inspection machine for extra-large OTR tires provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

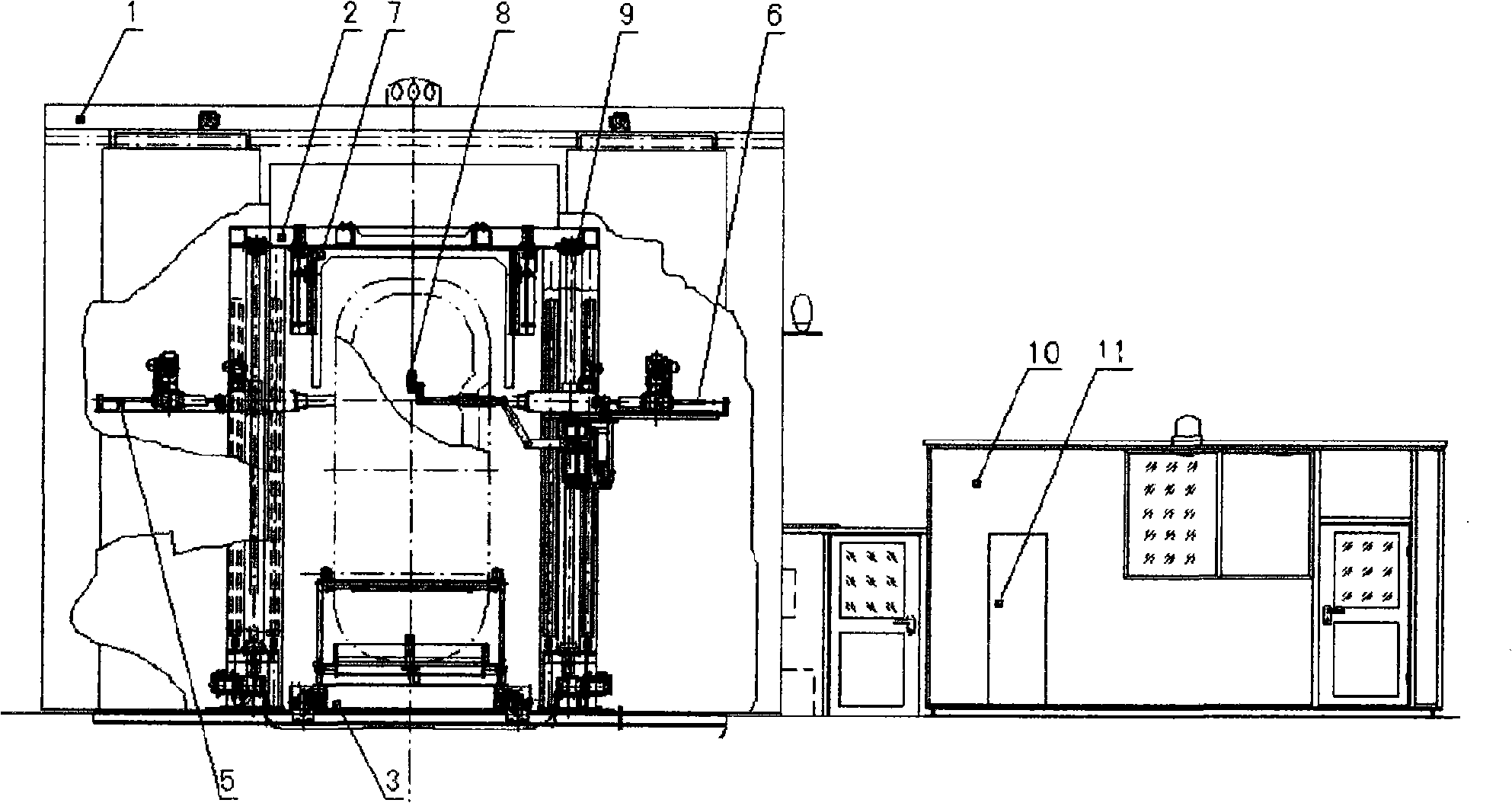

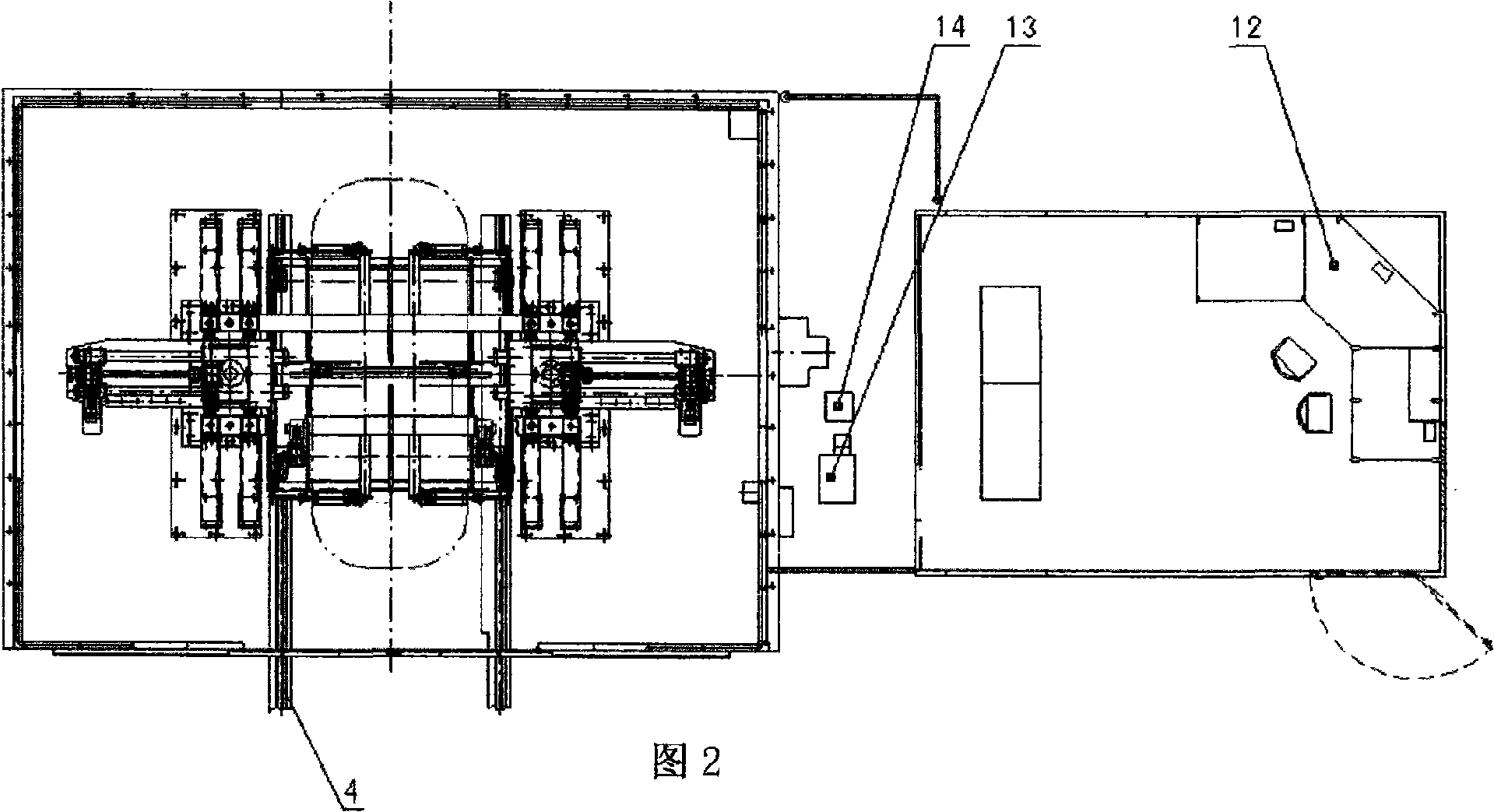

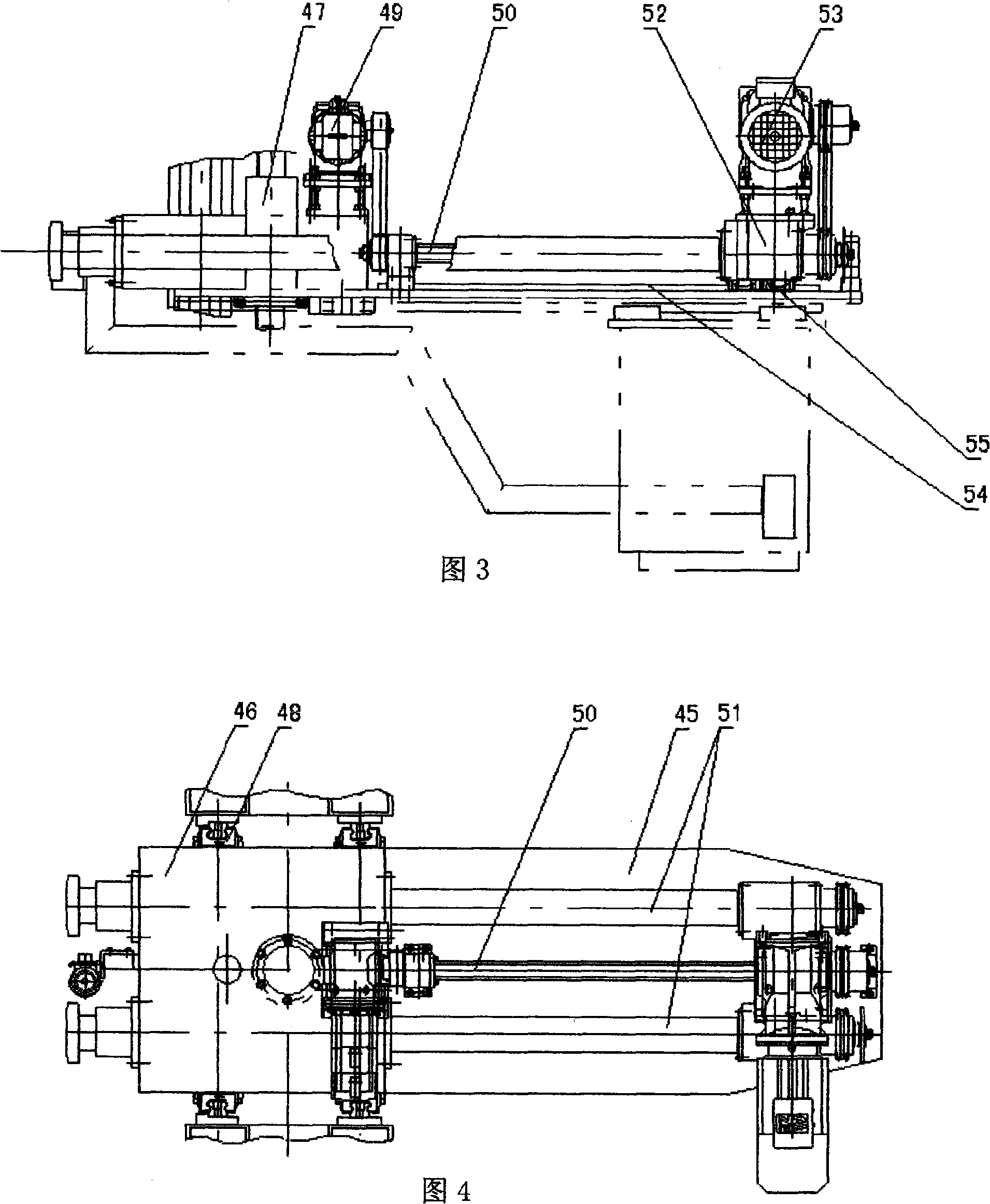

[0020] Such as figure 1 , as shown in Fig. 2, the X-ray inspection machine for extra-large engineering tires provided by the present invention is composed of a lead room 1, a fixed frame group 2, a tire transport positioning vehicle 3, a track 4, a left support shaft group adjustment device 5, and a right support shaft Group adjustment device 6, adjustable U-shaped X-ray receiving device 7, ray emission ball head adjustment mechanism 8, lifting mechanism group 9, isolated main control room 10, electrical control cabinet system 11, detection feedback display system 12, high-voltage electric energy generation 13 and water circulation cooling system 14; wherein the fixed frame group 2 is set in the lead room 1, the two sides of the fixed frame group 2 are fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com