Support ring of needle-stand sealing ring assembling device of safe self-destruction injection syringe

A sealing ring and syringe technology, applied in the field of medical machinery, can solve the problems of low assembly speed, needle seat pollution, unqualified product hygiene requirements, etc., and achieve the effects of simple structure, stable operation and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

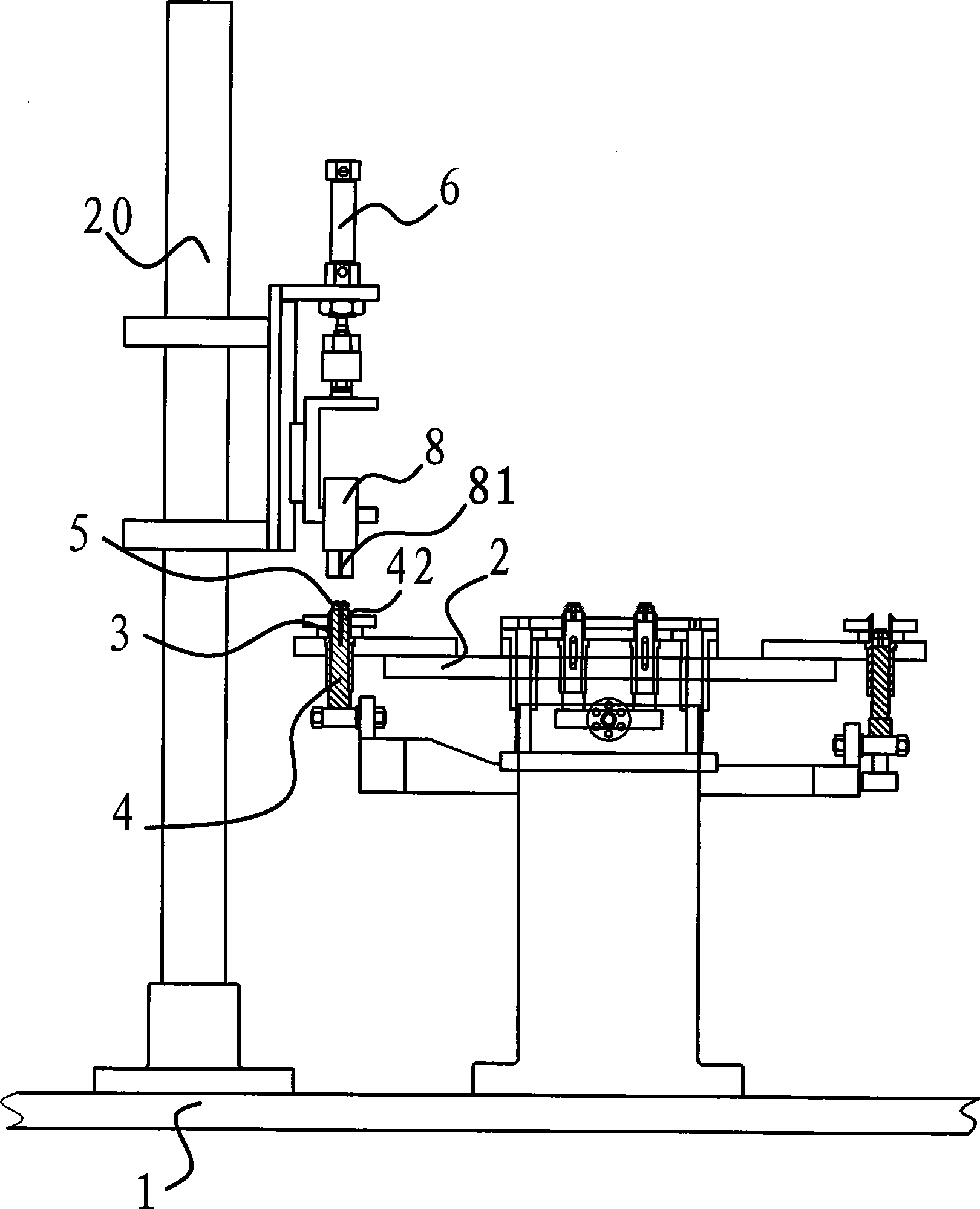

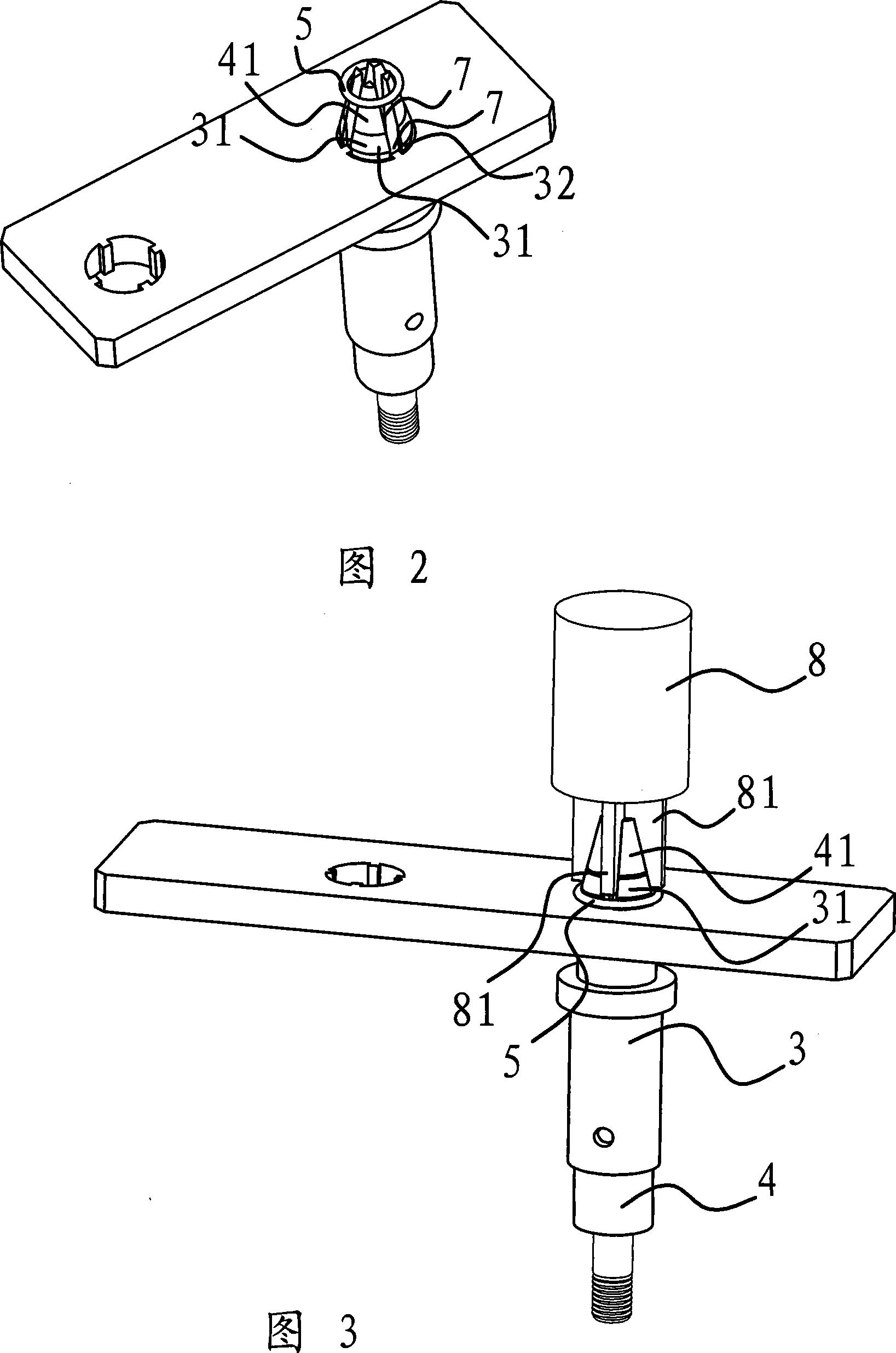

[0032] Such as figure 1, shown in Figure 2 and Figure 3, the support ring device of the needle seat sealing ring assembly machine of the safety self-destructing syringe is arranged on the support 1 between the feeding station of the sealing ring assembly machine and the sealing ring assembly station A turntable 2 is arranged on the machine base 1, and several sleeves 3 are arranged vertically at the edge of the turntable 2. The upper end of the sleeve 3 is conical, and a ring-shaped groove 32 is formed on the outer surface of the sleeve 3. After the sealing ring 5 is pushed down, the sealing ring 5 falls into the groove 32. The depth of the groove 32 is very shallow. After the sealing ring 5 falls into the groove 32, the sealing ring 5 can be easily removed from the groove. Slot 32. A support rod 4 is provided in the sleeve 3, the upper end of the support rod 4 stretches out from the sleeve 3 and the minimum inner diameter of the rod body 42 of the support rod 4 is the same a...

Embodiment 2

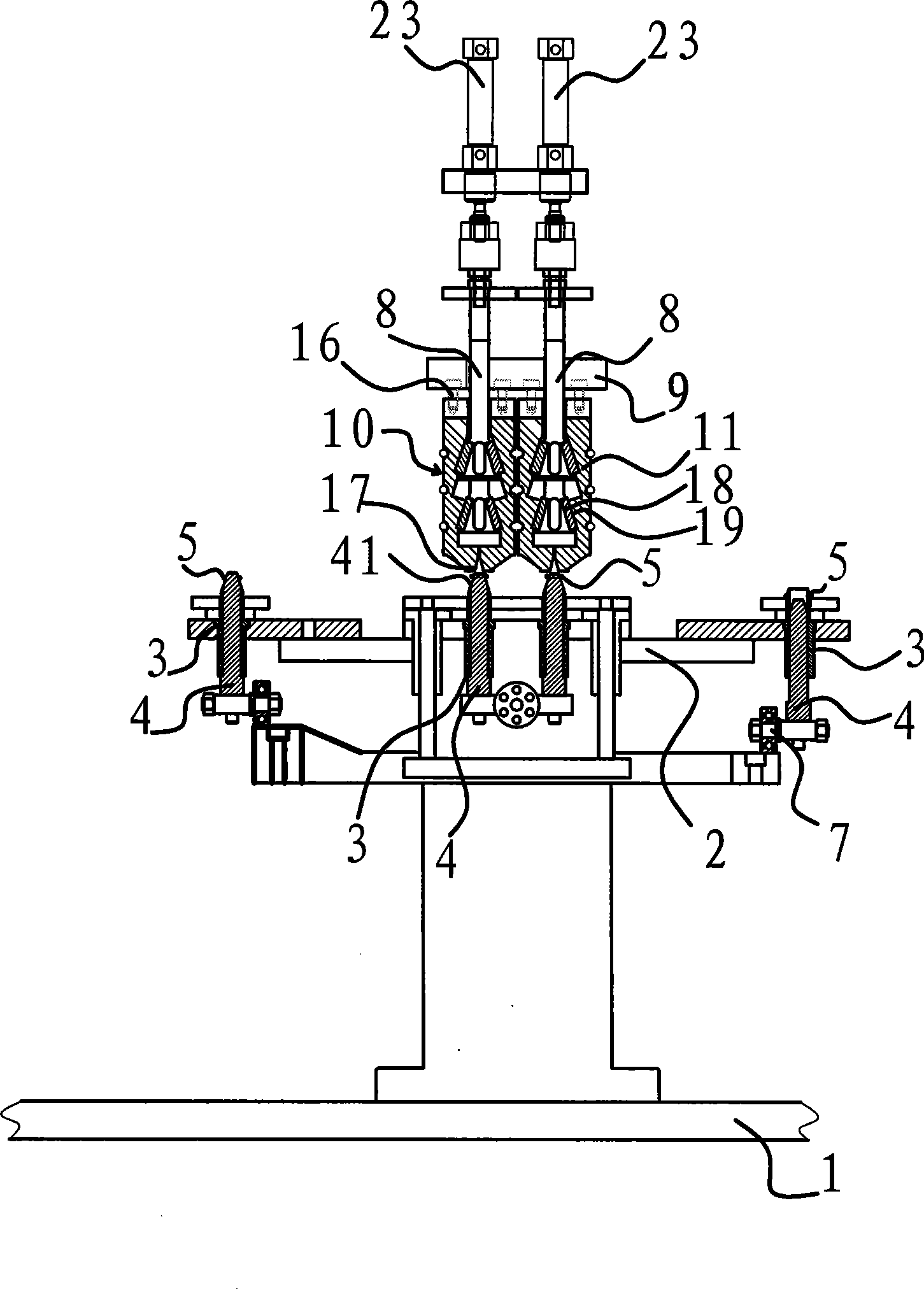

[0037] The content of embodiment 2 is basically the same as the content of embodiment 1, and its difference is, as Figure 4 As shown, the ring-pushing mechanism includes a ring-pushing mechanism including a fixed shaft 21 fixed on the base 1, a support plate 9 and a lift cylinder 23 that drives the support plate 9 to move up and down. The combined cylinder 10 that moves axially relative to the fixed shaft 21, the combined cylinder 10 is formed into a cylindrical shape surrounded by four push blocks 11, each push block 11 is horizontally slidably connected to the support plate 9, and the fixed shaft 21 and the push block 11 There is a separation structure between them when the support plate 9 moves down so that the combined cylinder 10 pushes the sealing ring 5 on the support rod 4 and the push block 11 is horizontally separated. Push block 11 is folded into two groups of elastic rings 12 of cylindrical shape. When the support plate 9 is in the original position, the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com