Nozzle cleaning device and cleaning method

A technology for cleaning devices and nozzles, which is applied in the manufacturing of spray devices, electrical components, semiconductor/solid-state devices, etc., and can solve the problems of impossible coating, exposed slit nozzles, and prolonged exposure of nozzles to the outside.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

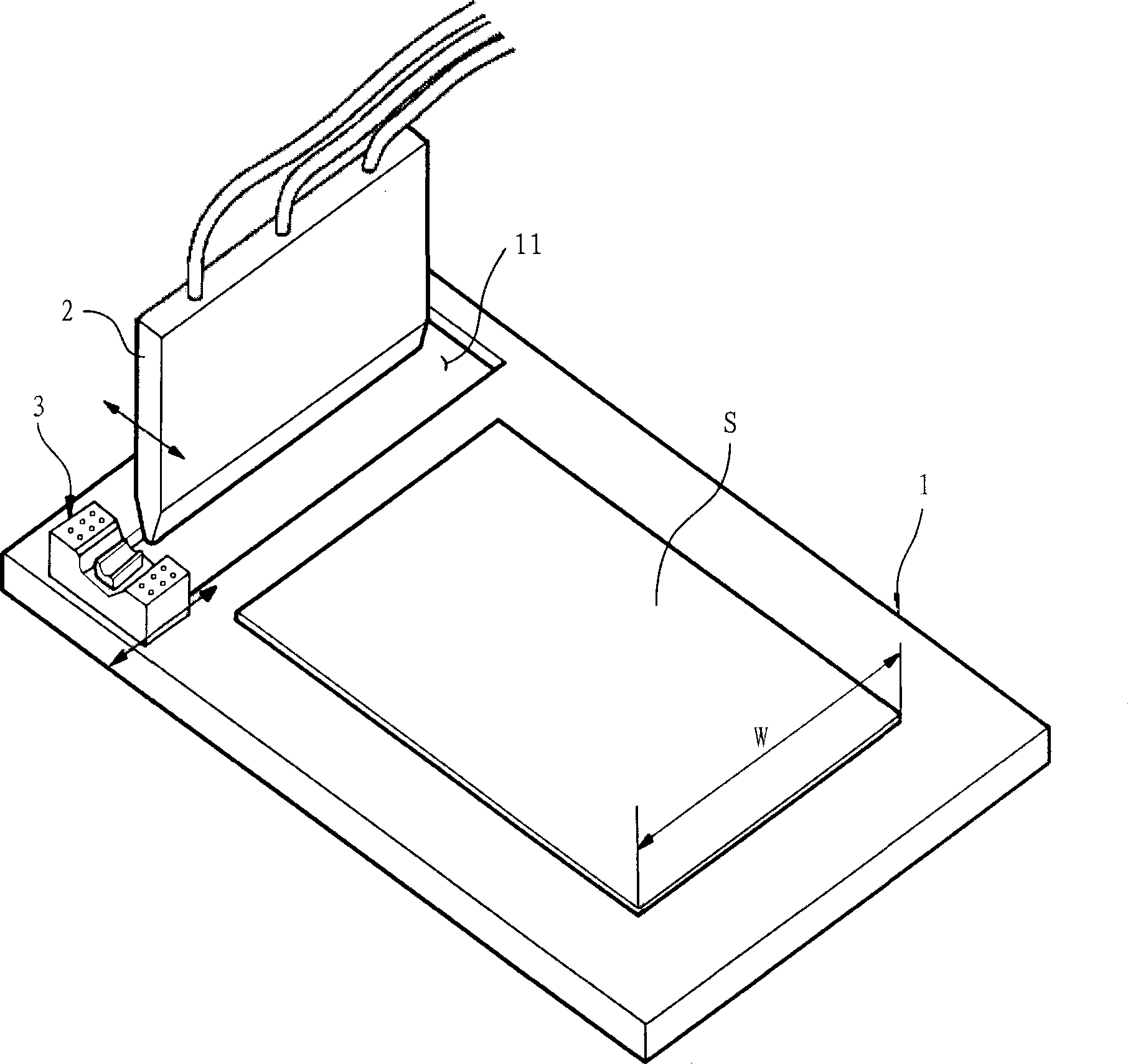

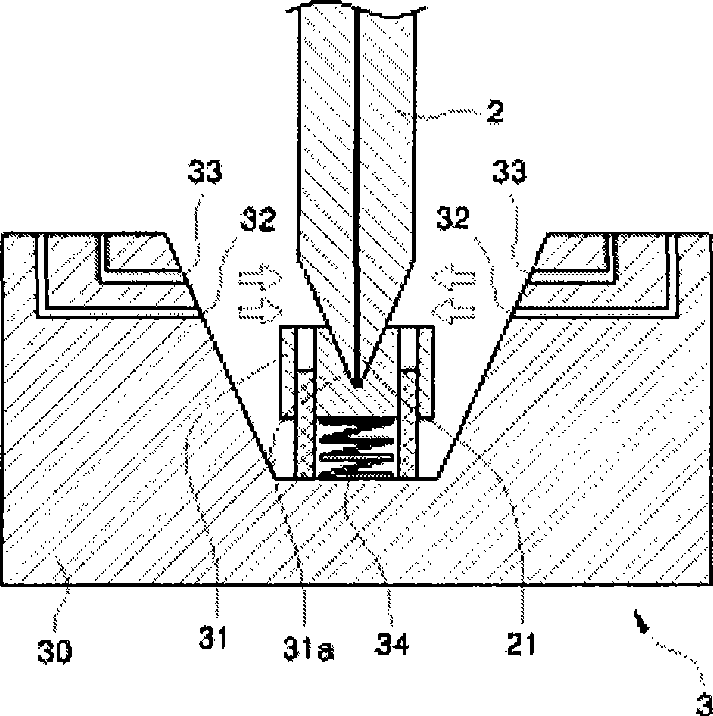

[0031] image 3 with Figure 4 It is a side structural view and a perspective view briefly showing the nozzle cleaning device provided according to the embodiment of the present invention.

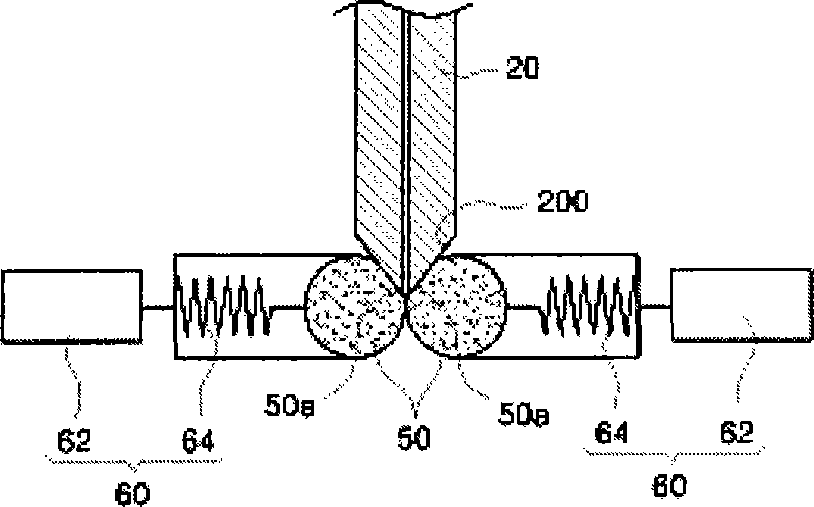

[0032] Such as image 3 with Figure 4 As shown, the nozzle cleaning device includes: a pair of facing cleaning blocks 50 whose length corresponds to the length in the width direction of the slit nozzle 20 ; and a moving part 60 that moves the pair of cleaning blocks 50 forward and backward. Through the operation of the moving part 60 , the pair of cleaning blocks 50 are in close elastic contact with each other with the slit nozzle 20 in the middle, so as to perform contact cleaning on the slit nozzle 20 .

[0033]Specifically, a pair of the cleaning blocks 50 are arranged to face each other with the slit nozzle 20 interposed therebetween. This pair of cleaning block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com