Conical-double-screw extruder for producing XPS thermal insulation board

A twin-screw extruder, insulation board technology, applied in the application, household appliances, other household appliances and other directions, can solve the problem of unable to produce XPS insulation board and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiments and drawings.

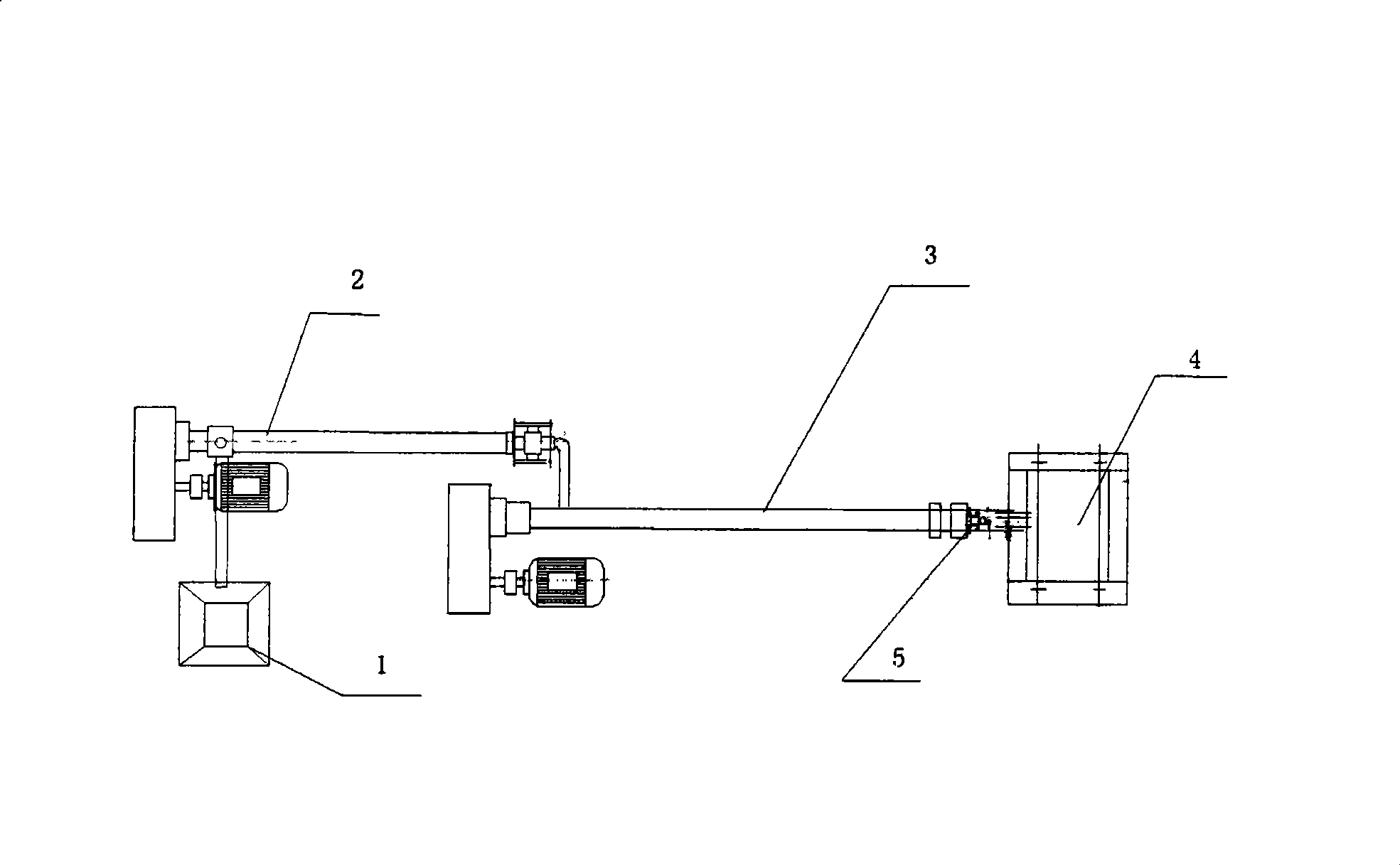

[0014] see figure 1 As shown, the conical twin-screw extruder 2 and the single-screw extruder 3 of the present invention are combined in series to form "one double cone, one single and double stage" to produce XPS insulation board, and the feeding mechanism 1 sends the raw materials into the first stage cone. The twin-screw extruder 2 performs mixing, melting and plasticization, and then enters the second-stage single-screw extruder 3, and foams in the shaping device 4 through the extrusion die 5 to obtain a molded product.

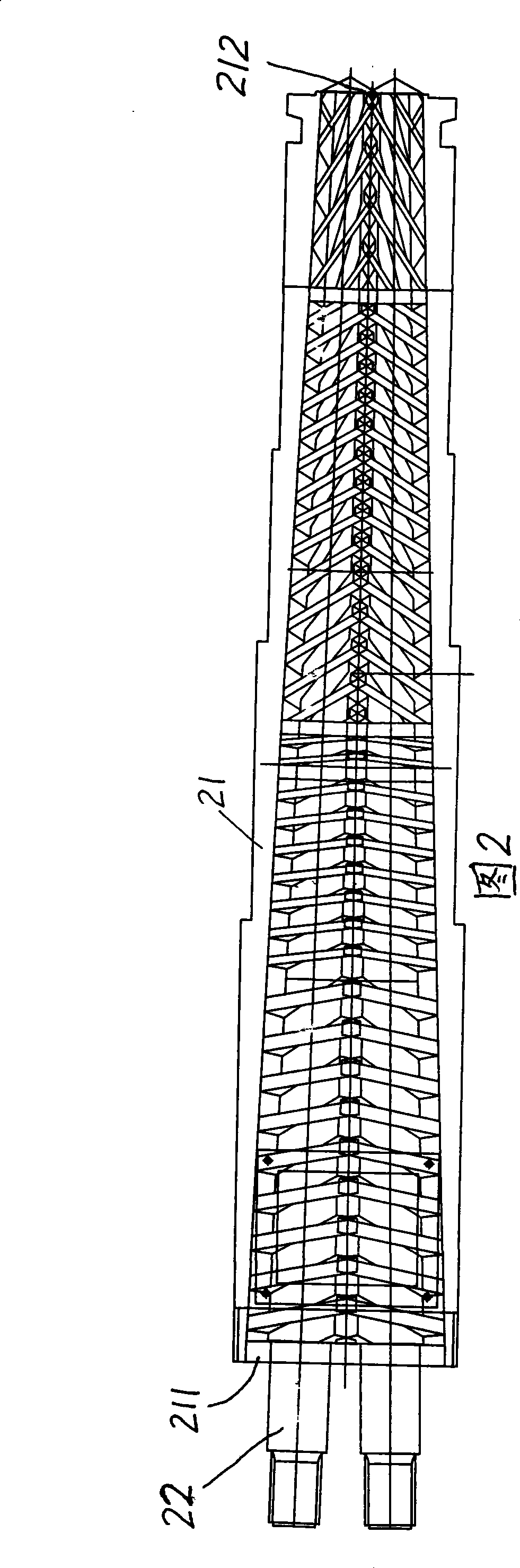

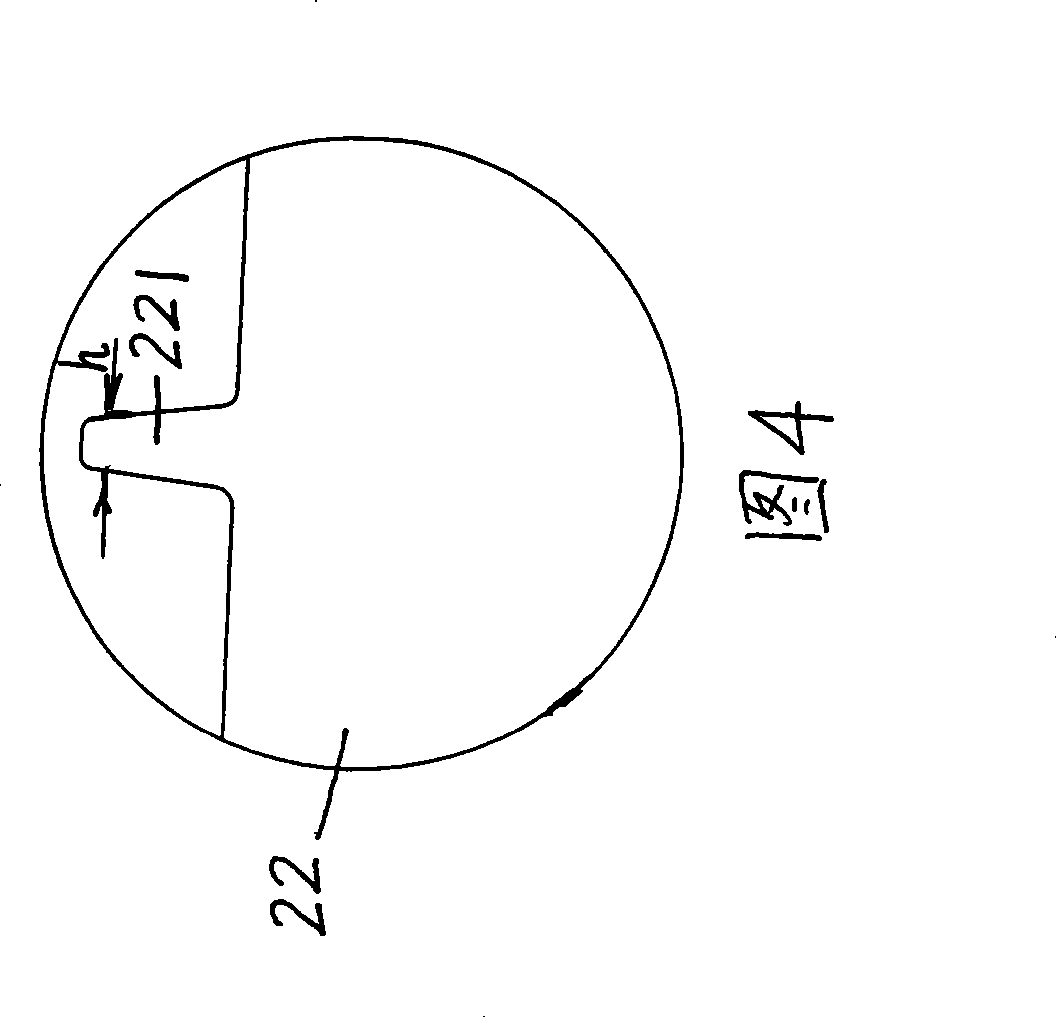

[0015] As shown in Figure 2 and Figure 3, the barrel 21 of the conical twin-screw extruder 2 is a continuous and uninterrupted sealed barrel structure from the inlet 211 to the outlet 212, which eliminates the existing conical double-screw extruder. The opening of the barrel of the screw extruder also eliminates the suction pump, so that it can be appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com