Multi-domain vertical alignment mode liquid crystal display panel and method for producing same

A liquid crystal display panel, vertical alignment technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of light leakage that cannot be completely solved, limited light leakage reduction, reduced device transmittance and brightness, etc. Effects of phase delay, improved contrast and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

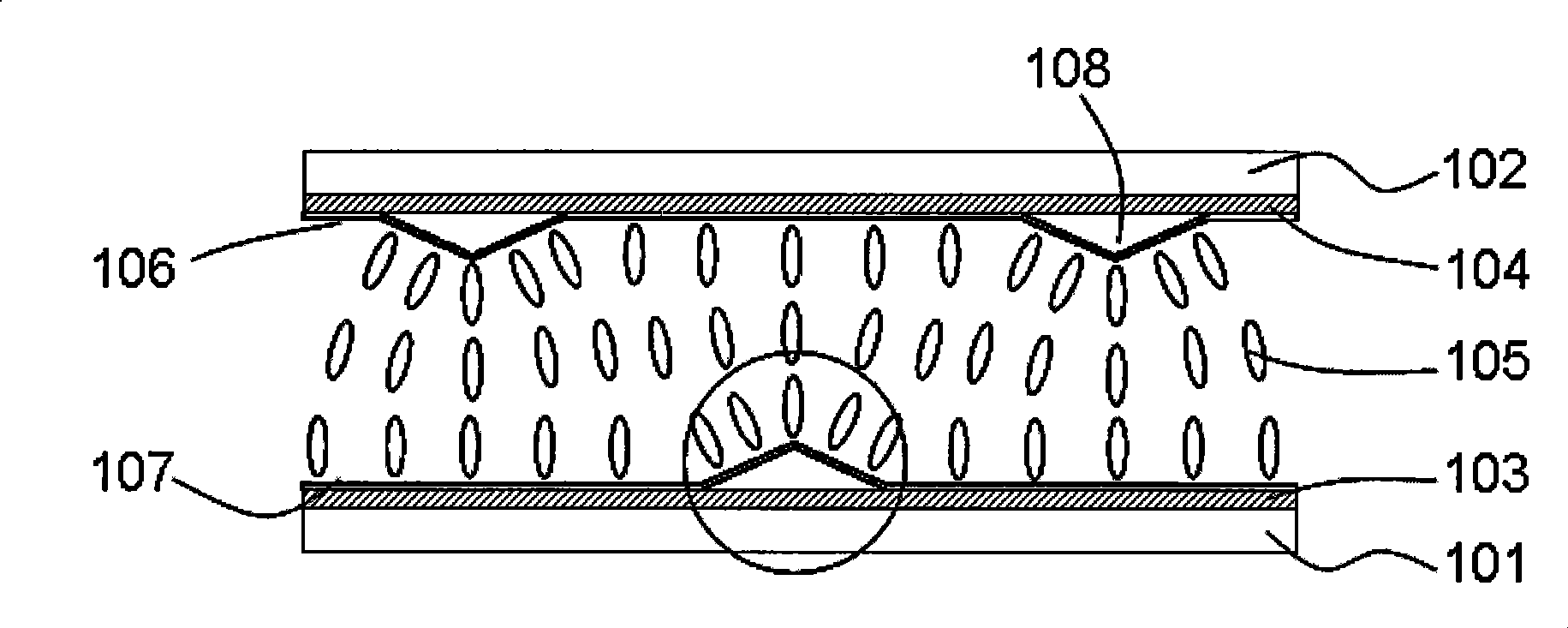

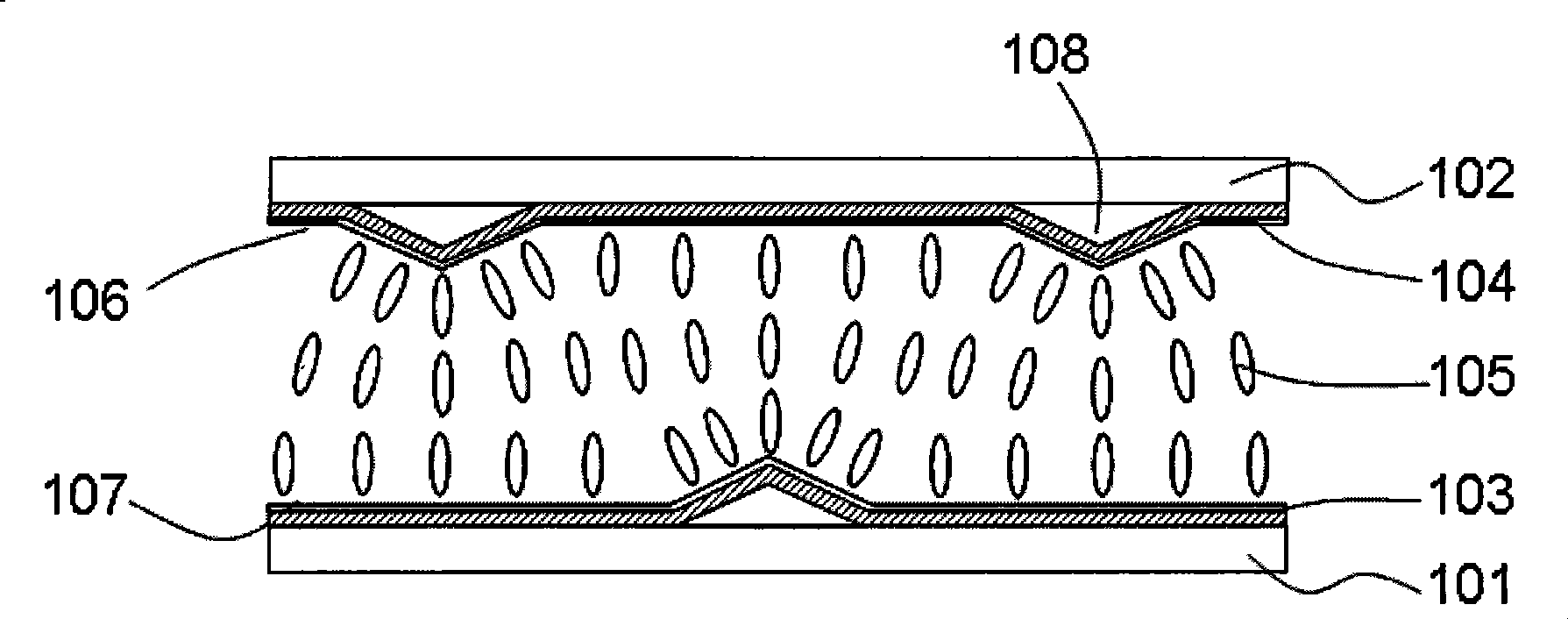

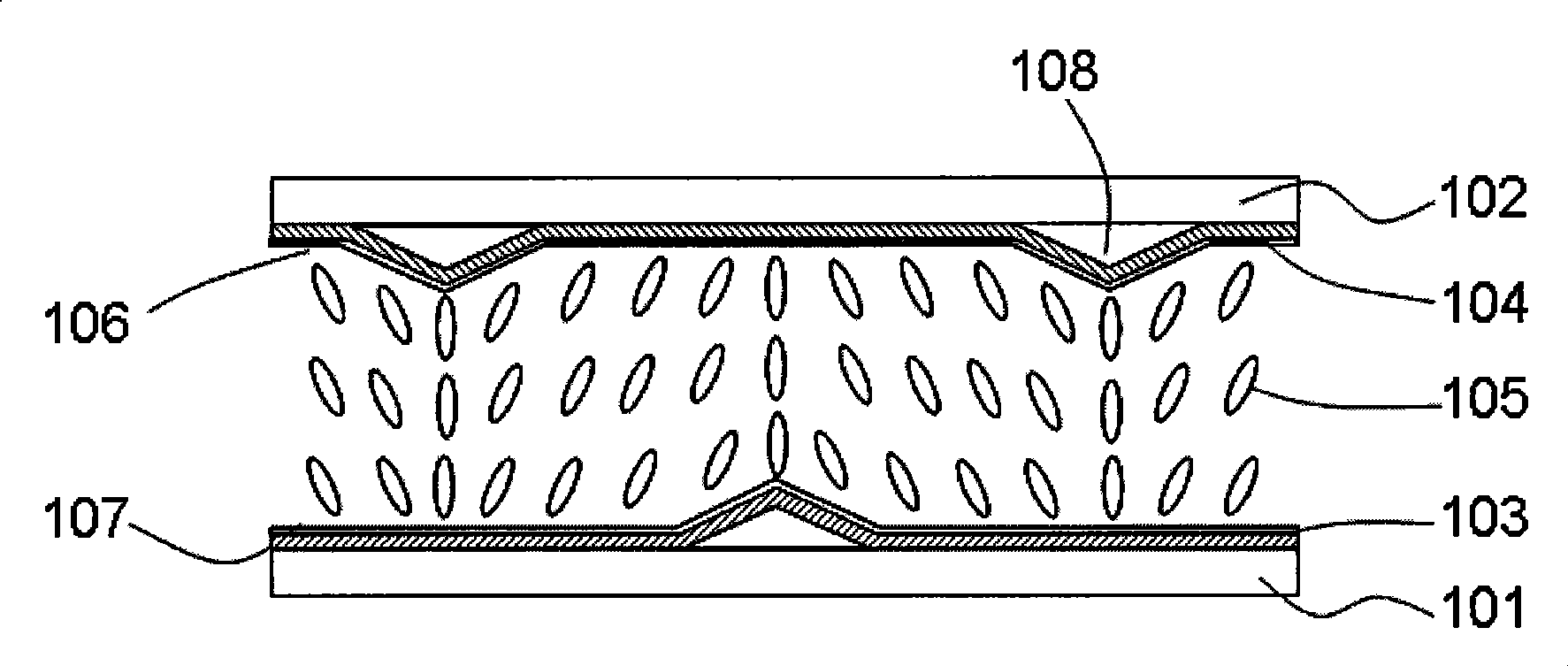

[0036] Please refer to FIG. 2 for the multi-domain vertical alignment liquid crystal display panel of the present invention, which includes an array substrate 101 and a color filter substrate 102 placed parallel to each other, and liquid crystal molecules 105 sandwiched between the two substrates. There are transparent electrodes 103 and 104 and vertical alignment films 106 and 107 on the array substrate 101 and the color filter substrate 102 respectively. Alignment protrusions 108 are disposed on the array substrate 101 and / or the color filter substrate 102 .

[0037] image 3 It is a schematic diagram of the implementation process of the present invention.

[0038] See image 3 , add a photo / thermal curing polymer to the liquid crystal, in this embodiment, the liquid crystal acrylate monomer UCL-001 manufactured by Dainippon Ink and Chemicals, Inc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com