Digital controlled demonstrator for failure of gear transmission

A gear transmission and demonstration device technology, applied in instruments, educational appliances, teaching models, etc., can solve the problems of long test period, high cost, and lack of judging gear failure modes on the gear life test bench, so as to broaden the content of the system teaching experiment. , Small size, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

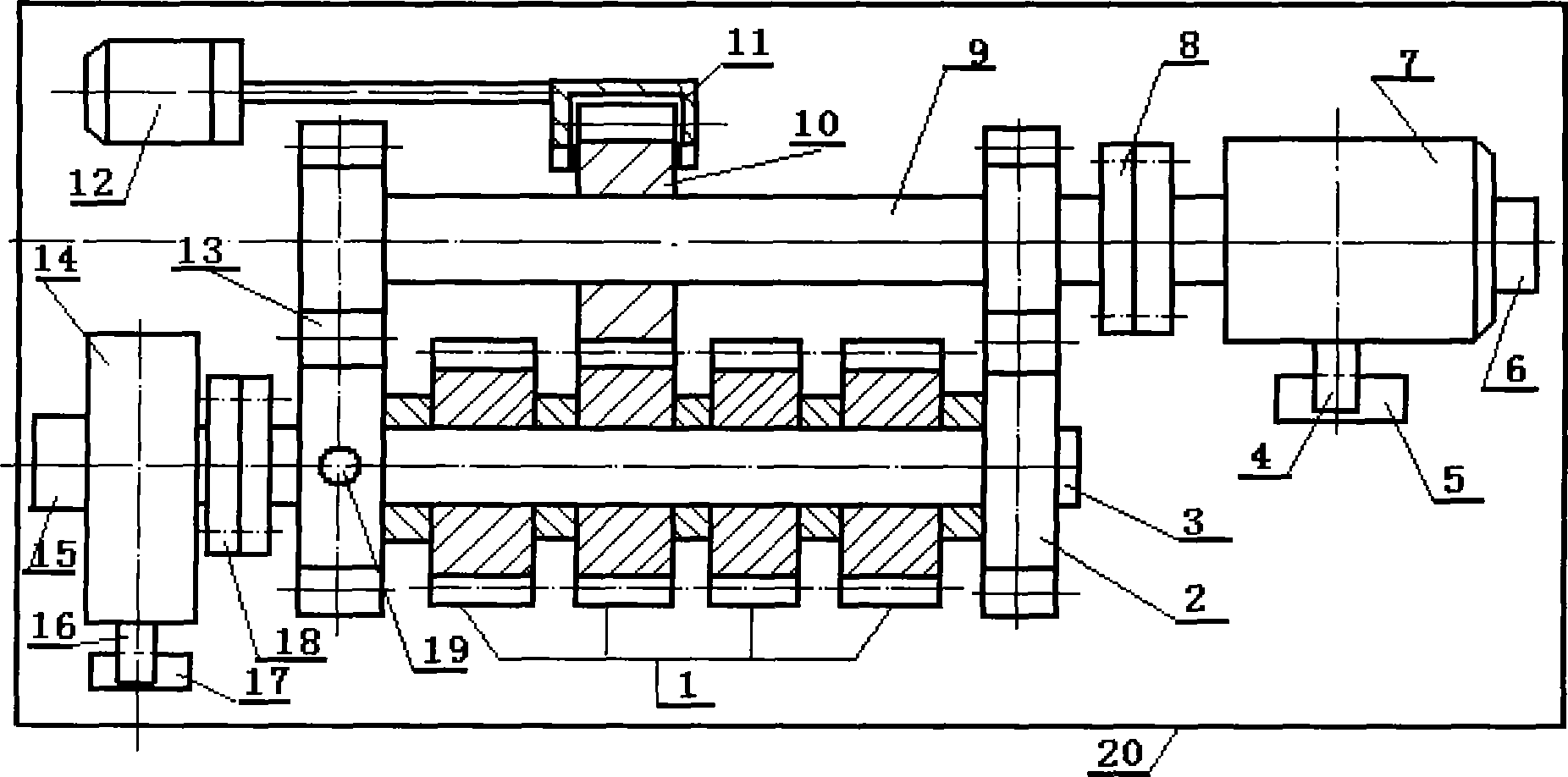

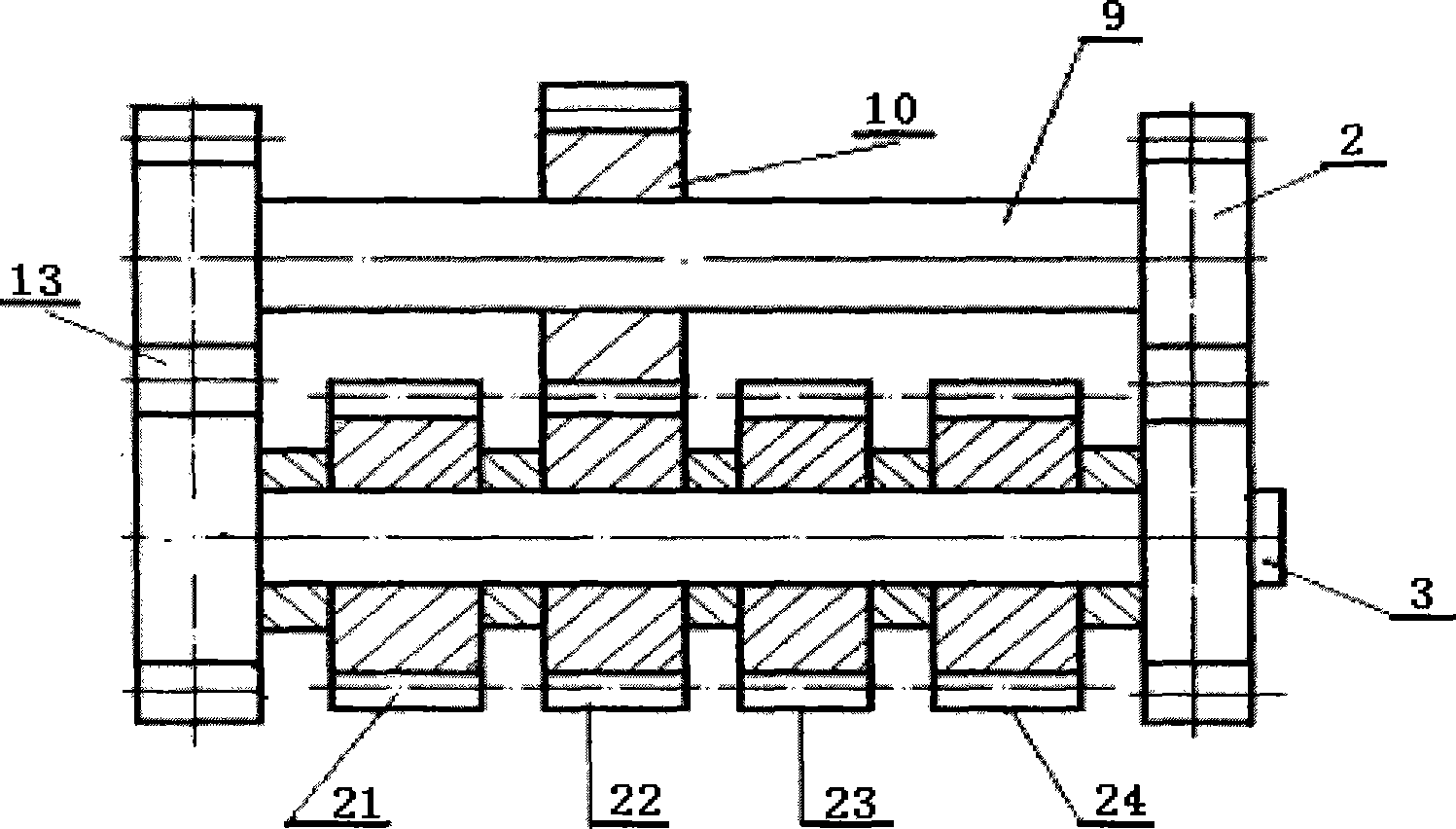

[0014] The present invention is a kind of numerical control demonstrator which integrates the demonstration of gear failure, rotation efficiency and rotation precision, and can realize the teaching experiment of the transmission phenomenon after the failure form occurs in the gear transmission system. Its structure is as follows figure 1 As shown: it is mainly composed of gear failure characteristic group 1, magnetic powder clutch 14, vibration sensor 19, speed change system, motor drive system, force sensor, numerical control system and data acquisition and processing system, which are installed on the machine base 20. The gear failure feature group 1 is installed on the transmission shaft 3 , and the transmission shaft 3 is installed on the base 20 through the first bearing seat 2 and the second bearing seat 13 . The left end of the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com