Method for lithium battery injection molding encapsulation

A technology of lithium batteries and batteries, which is applied in the field of plastic packaging of battery components, can solve the problems of high precision and process requirements of injection molding equipment, difficulty in meeting equipment requirements, and increased battery thickness. The effect of low and high injection molding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for injection molding and encapsulating lithium batteries of the present invention will be described in detail below through specific embodiments

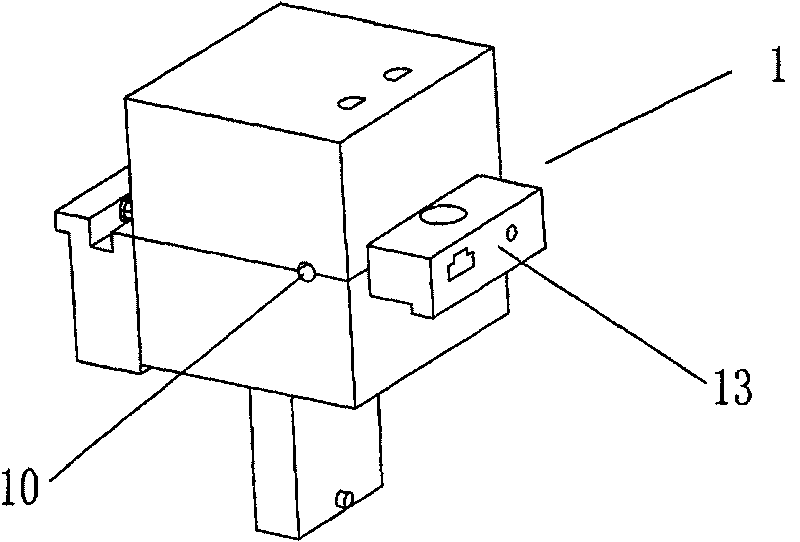

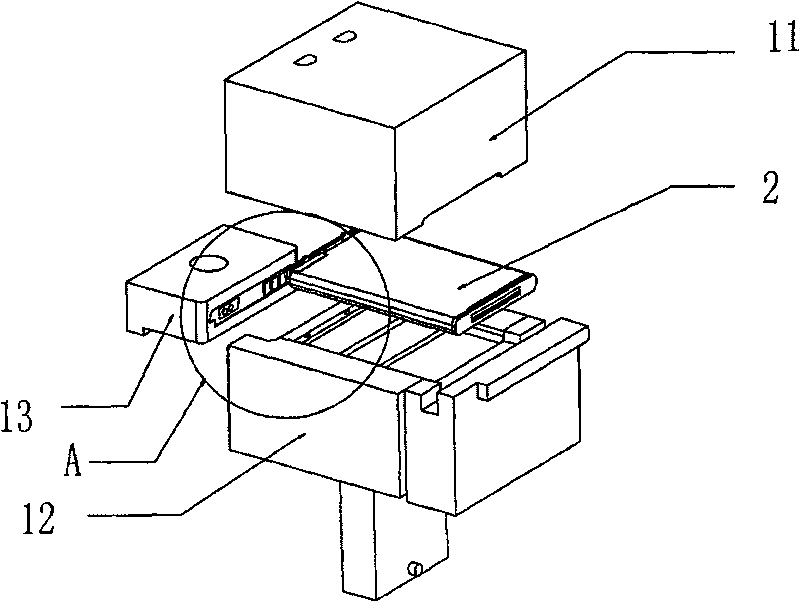

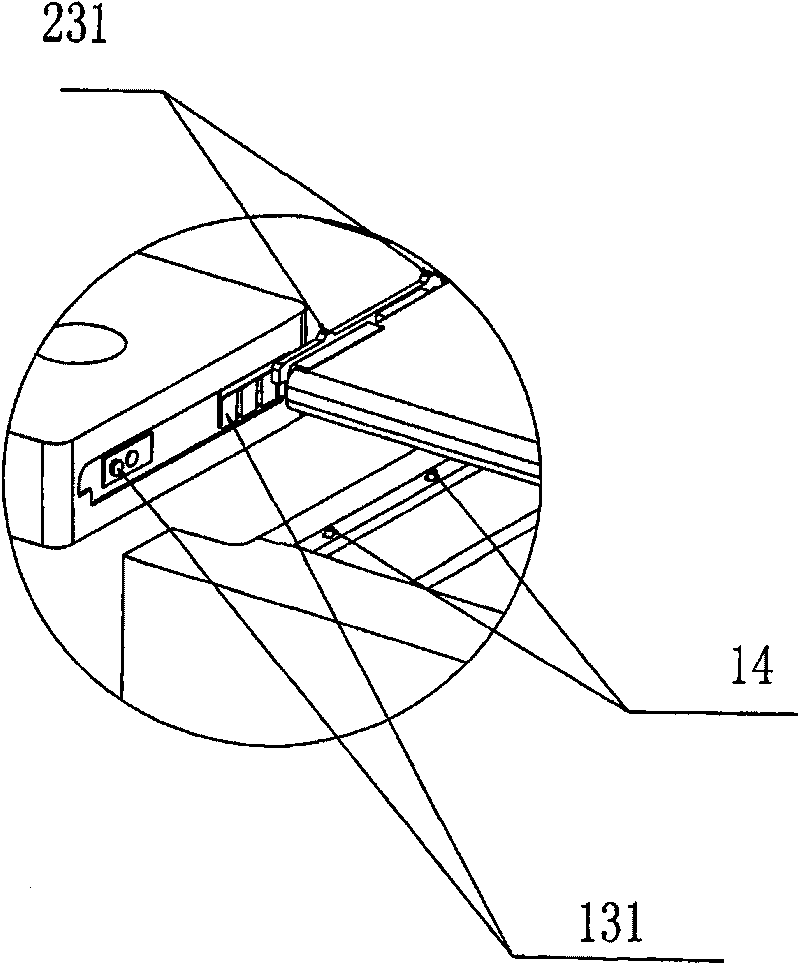

[0029] The method of the invention can form a surface cover for encapsulating the electric core assembly, and the surface cover wraps the electrode end of the electric core and the output terminal of the electric core therein. The mold that adopts in the inventive method is as Figure 1~3 As shown, the mold includes an upper mold 11 and a lower mold 12, the upper mold and the lower mold respectively have inner concave parts, and the inner concave parts of the upper and lower molds are combined to form an injection molding cavity, and the cell assembly 2 to be packaged is placed in the cavity Inside. A glue injection hole is provided at the joint of the upper and lower molds, and thermoplastic resin is injected through the glue injection hole 10, and an injection molded surface cover is formed on the front surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com